Understanding the Importance of Accurate Measurements

The Significance of Precision in Various Fields

Accurate measurements are paramount in various fields, including engineering, manufacturing, and scientific research. Precision ensures that components fit together perfectly, products function as intended, and experimental results are reliable. For instance, in the aerospace industry, the precision of parts can be the difference between a successful flight and a catastrophic failure. Similarly, in scientific research, accurate measurements allow for reproducibility and the validation of hypotheses. Thus, the importance of precision cannot be overstated.

What is a Micrometer?

Definition and Purpose

A micrometer, often known as a micrometer screw gauge, is a device used for precise measurement of small distances, thicknesses, and diameters. Unlike other tools, a micrometer incorporates a calibrated screw mechanism, which allows for fine adjustments and highly accurate readings. In various fields, the micrometer plays a critical role in ensuring components meet stringent standards and specifications.

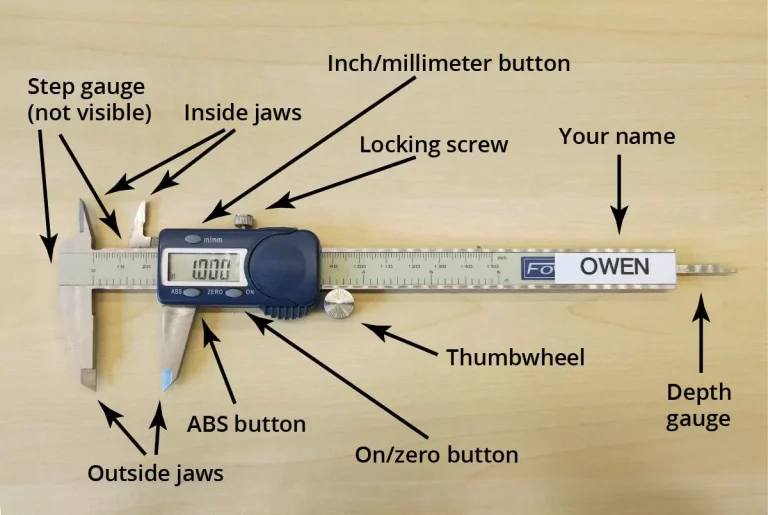

Key Components of a Micrometer

Sleeve with Scale

The sleeve of a micrometer contains a fixed scale marked with increments. This part of the micrometer remains stationary and provides the baseline measurement. Typically, the sleeve will display millimeter or inch graduations, serving as the reference against which further measurements are read.

Thimble with Scale

Attached to the calibrated screw, the thimble rotates and advances over the sleeve. The thimble is marked with additional graduation lines that represent finer increments, allowing users to read minutiae beyond what the sleeve provides. This interplay between the sleeve and thimble is what guarantees the micrometer’s high level of accuracy.

Vernier Scale

Some micrometers incorporate a vernier scale for even greater precision. This secondary scale allows for additional subdivisions, offering increased accuracy by providing measurements to tenths or even hundredths of the smallest units marked on the thimble. The vernier scale is particularly valuable in scientific research and high-precision engineering.

Anvil and Spindle

The anvil and spindle are the contact points of the micrometer used to secure the object being measured. The anvil is a fixed point, while the spindle moves towards or away from the anvil as the thimble is turned. These components ensure a secure and accurate position for the object, essential for obtaining precise measurements.

Measurement Range and Increments

Standard Size Increments (1 inch, 25mm)

Micrometers are typically available in standard measurement ranges, such as 0-1 inch or 0-25 millimeters. Each micrometer is designed to measure within this specific range, specified in precise increments, often down to thousandths of an inch or hundredths of a millimeter. These small increments make micrometers particularly well-suited for tasks requiring exceptional precision, such as in mechanical engineering and material science.

Types of Micrometers

Inside Micrometers

Inside micrometers are specifically designed to measure the inner dimensions of an object, such as the diameter of a hole or the distance between two internal surfaces. Unlike outside micrometers, these tools often feature a set of interchangeable rods or anvils to suit various measurement ranges. This versatility is crucial in applications like engine rebuilding or precision machining, where internal measurements must be exact to ensure compatibility and functionality.

Outside Micrometers

Outside micrometers are the most common type and are used for measuring the outside dimensions of an object, such as the diameter of a rod or the thickness of a plate. These micrometers are widely used in quality control processes across engineering and manufacturing sectors. Their precision enables accurate measurement of components, ensuring they meet specified tolerances and contributing to the reliability and performance of the final product.

Depth Micrometers

Depth micrometers are specialized tools designed to measure the depth of holes, slots, or recesses. These instruments consist of a flat base and a measuring rod that extends into the measured feature. Depth micrometers are particularly useful in tasks such as machining or construction, where precise depth measurements are critical for ensuring parts fit together correctly and function as intended.

Steps to Using a Micrometer Efficiently

Preparation for Measurement

Securing the Object to be Measured

Before using a micrometer, it is essential to properly secure the object being measured to prevent any movement that could affect the accuracy of the reading. Depending on the measurement context, this could involve using a vise, clamp, or other stabilization method to hold the object securely in place. Ensuring the object is stable is the first step in obtaining a precise and reliable measurement.

Selecting the Appropriate Micrometer

Choosing the correct micrometer for the measurement task is crucial. Assess the size and type of the object, and select a micrometer with a suitable range and type—either inside, outside, or depth micrometer. Using an inappropriate tool can result in inaccurate measurements and may even damage the micrometer or the object being measured.

Detailed Measuring Process

Loosening the Thimble

Begin by loosening the thimble of the micrometer, which allows the spindle to move freely. This step is essential as it ensures that the spindle and anvil can be positioned correctly around the object without applying excessive force. Properly loosening the thimble ensures an accurate and secure placement for measurement.

Positioning the Spindle and Anvil Correctly

Carefully place the spindle and anvil around or within the object to be measured. Make sure that the contact points are aligned correctly and are fully in contact with the object’s surfaces. Misalignment can lead to measurement errors, so taking the time to position the spindle and anvil accurately is crucial for achieving precise results.

Adjusting the Thimble Properly

Once the spindle and anvil are correctly positioned, gently turn the thimble to close the gap between them until they touch the object. Ensure that the thimble is turned smoothly and evenly, to avoid applying uneven pressure. Accurate adjustment of the thimble is key to obtaining a reliable measurement without compromising the object’s integrity.

Importance of Avoiding Excessive Force

Applying too much force can damage both the micrometer and the object being measured. Use gentle pressure to ensure that the measurement is true to the object’s actual dimensions. Most micrometers include a ratchet mechanism designed to limit the force applied, ensuring consistent, gentle pressure during measurement.

Utilizing the Ratchet Mechanism

The ratchet mechanism provides a controlled and consistent amount of force to minimize user variability in measurements. Once the spindle and anvil are in position, turn the ratchet knob until it clicks. This mechanism ensures an even application of pressure, enhancing the accuracy and repeatability of the measurement.

Reading the Micrometer Scale Effectively

Traditional Scale System Explained

Understanding the Sleeve Scale

The sleeve scale of a micrometer indicates the larger increments of the measurement. Look at the markings on the sleeve to determine the base measurement. The lines on the sleeve represent the millimeters or inches, and accurate reading of these lines is the first step in interpreting the micrometer’s measurement.

Deciphering the Barrel Scale

The barrel scale, or thimble scale, provides the finer increments of the measurement. These lines represent fractions of the units indicated on the sleeve scale. By aligning the appropriate line on the thimble with the marking on the sleeve, you can determine the precise additional measurement beyond the base provided by the sleeve scale.

Utilizing the Vernier Scale

For micrometers equipped with a vernier scale, this additional scale allows for even finer measurements. The vernier scale typically measures in tenths, enabling precision to a fraction of the smallest unit on the thimble. By carefully aligning the vernier scale’s lines with the thimble’s markings, one can achieve an exceptionally precise measurement.

Example Calculation for Clarity

To illustrate, suppose the sleeve scale reads 10 mm, the thimble scale reads 0.5 mm, and the vernier scale reads 0.03 mm. The final reading would be 10 + 0.5 + 0.03 = 10.53 mm. This precise interpretation of the combined scales highlights the micrometer’s ability to deliver exact measurements critical in high-precision applications.

Digital Scale System Advantages

Benefits of Digital Micrometers

Digital micrometers automate the reading process, offering an easily readable digital display that eliminates the potential for human error in interpreting the scale. These tools are user-friendly and reduce the complexity associated with traditional micrometer scales. The ease of reading and recording measurements makes digital micrometers a valuable tool in environments where speed and accuracy are paramount.

Understanding Digital Readouts

Digital readouts on micrometers provide an instantaneous display of the measurement, often to several decimal places. This automatic calculation saves time and reduces the risk of errors, making digital micrometers ideal for high-throughput environments. The clear, straightforward display ensures that users can quickly and accurately obtain the necessary measurements.

Final Thoughts on Using a Micrometer for Accurate Measurements

Recap of Essential Points Covered

Throughout this guide, we have covered the critical aspects of utilizing a micrometer for precise measurement. Beginning with the importance of precision, we compared common measuring tools and highlighted the superior accuracy of micrometers. We explored the different types of micrometers, their key components, and the steps involved in using them effectively. Additionally, we discussed how to read both traditional and digital micrometer scales.

Overall Benefits of Micrometers in Achieving Precision

Micrometers are indispensable tools for achieving high levels of precision in various fields. Their ability to measure with unparalleled accuracy makes them critical in industries where exact dimensions are crucial. By following the steps and techniques outlined in this guide, users can ensure they obtain reliable, precise measurements, contributing to the quality and integrity of their work. Whether in engineering, manufacturing, or scientific research, the micrometer remains a cornerstone of precision measurement tools.