Understanding Hardened Steel

Definition of Hardened Steel

Hardened steel is a type of steel that has undergone specific heat treatment processes to enhance its hardness and strength. This metal is particularly valued in industries that require durable and wear-resistant materials. By altering its internal structure through controlled heating and cooling techniques, hardened steel exhibits increased ability to resist deformation and withstand heavy use without significant wear.

Production Process

The production of hardened steel involves two key processes: quenching and tempering. These processes are carefully controlled to achieve the desired mechanical properties.

Quenching

Quenching is the initial stage in the hardening process. During quenching, the steel is heated to a high temperature, generally above its critical point, and then rapidly cooled. This sudden cooling locks the steel into a hard but brittle state. Quenching mediums can vary, including water, oil, or air, each contributing differently to the cooling rate.

Tempering

Tempering follows quenching and aims to reduce the brittleness of the quenched steel while retaining most of its hardness. During tempering, the steel is reheated to a temperature lower than its critical point and then slowly cooled. This process refines the microstructure of the steel, balancing hardness and toughness, making it more durable for practical applications.

Advantages and Disadvantages of Hardened Steel

Advantages

The enhanced properties of hardened steel make it a favored material for numerous industrial applications. Some of the primary advantages include:

Wear and Abrasion Resistance

Hardened steel is highly resistant to wear and abrasion, making it ideal for tools and machinery parts that face constant mechanical friction. This resistance ensures a longer lifespan and reduced maintenance costs for equipment.

Rust and Corrosion Resistance

Although not as inherently resistant as stainless steel, hardened steel can be treated with coatings or alloys to improve its rust and corrosion resistance. This enhancement extends the usability and effectiveness of the steel in various environments, including those with high moisture levels.

Disadvantages

Despite its many benefits, hardened steel is not without drawbacks. Understanding these disadvantages is crucial for selecting the right material for your specific needs.

Brittleness to Sharp Impacts

One significant disadvantage of hardened steel is its brittleness when subjected to sharp impacts. The increased hardness can make the material less able to absorb energy without fracturing, which could lead to potential failures in certain applications.

Sensitivity to High Temperatures

Hardened steel can lose its desirable properties when exposed to high temperatures. The heat can temper the material, reducing its hardness and making it more pliable, which may not be suitable for high-temperature applications unless specific steps are taken to mitigate this effect.

Rockwell Hardness of Hardened Steel

Rockwell Scale Overview

The Rockwell hardness scale is a standardized method for measuring the hardness of materials. The scale uses indentation hardness, which indicates how deeply a material is indented by a specific force applied with a designated indenter.

Typical Hardness Range for Hardened Steel

High Hardened Steels Classification (55-70HRC)

Hardened steels generally fall within the 55-70HRC range on the Rockwell C scale. This classification signifies a high level of hardness, making the steel suitable for applications that require enhanced wear resistance and durability. Tools, dies, and blades often use steel within this hardness range to ensure performance and longevity.

Machining Hardened Steel

Tool Selection

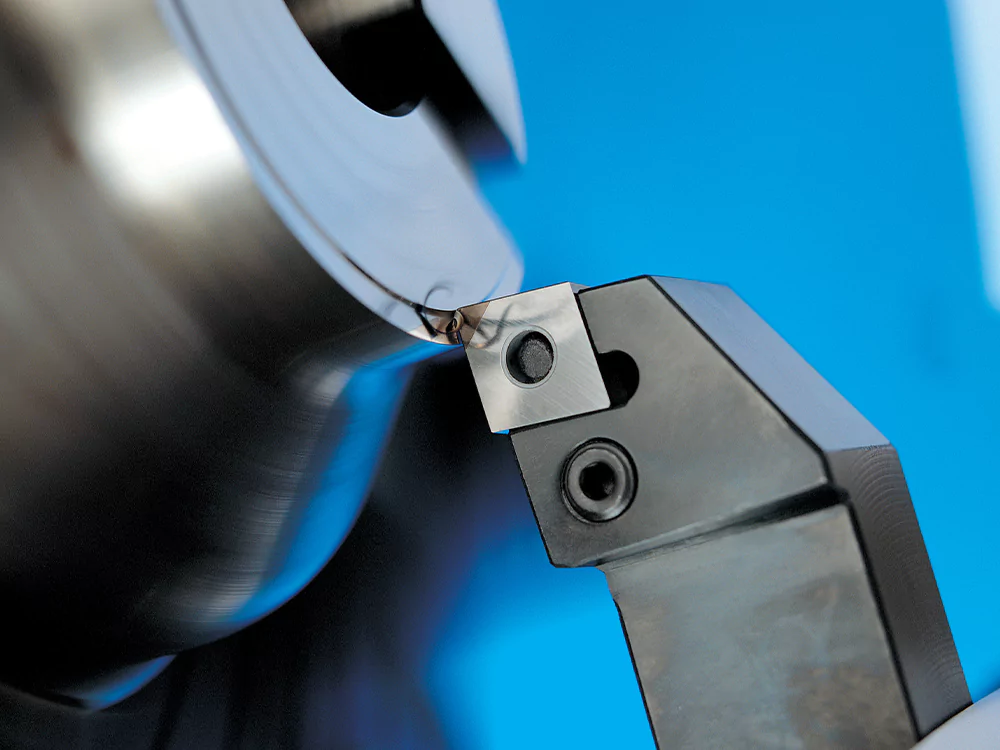

Selecting the right tools for machining hardened steel is critical for achieving precision and extending tool life. The two main types of tools used are ultrafine and nanograin carbide tools and CBN (Cubic Boron Nitride) tools.

Ultrafine and Nanograin Carbide Tools

Ultrafine and nanograin carbide tools are preferred for their robustness and longevity. Their fine grain structure provides the strength and wear resistance necessary to machine hardened steel effectively, reducing the frequency of tool changes.

CBN (Cubic Boron Nitride) Tools

CBN tools are another excellent option for machining hardened steel. These tools are exceptionally hard and maintain their integrity at high temperatures, making them ideal for prolonged use in demanding conditions. Their ability to cut through hard metals without significant wear leads to higher precision and efficiency.

Cutting Data (Speeds and Feeds)

Understanding the appropriate cutting data is paramount when working with hardened steel. This involves both the speeds at which tools move and the feeds, or the rate at which material is removed.

Manufacturer Recommendations

Manufacturers often provide detailed recommendations for cutting speeds and feeds specific to their tools. Following these guidelines ensures optimal performance and extends the tool’s lifespan while maintaining the quality of the machined part.

Adjustments for Optimal Performance

In some cases, adjustments to the recommended speeds and feeds may be required to optimize machining performance based on specific project needs. This could involve adapting the parameters to the material’s hardness, tooling life, and the desired surface finish, ensuring an efficient and effective machining process.

Modern High-Speed Tooling Technologies

Advancements in tooling technologies have revolutionized the machining of hardened steel, making it more efficient and cost-effective.

High Feed Rates and Small Cutting Depths

Modern high-speed tooling technologies allow for higher feed rates and smaller cutting depths, significantly improving machining efficiency. When combined, these techniques reduce the overall machining time while maintaining surface quality. The enhanced cutting parameters also lead to lower heat generation, which is advantageous when working with hardened steel that is sensitive to high temperatures.

EDM (Electric Discharge Machining)

Electric Discharge Machining (EDM) is a non-traditional method particularly useful for machining hardened steel. EDM employs electrical discharges to remove material, making it possible to create complex shapes and intricate details without direct contact between the tool and workpiece. This method is especially beneficial for materials that are difficult to machine using traditional techniques.

Key Factors for Successful Machining

Effective machining of hardened steel hinges on several key factors that ensure precision, efficiency, and tool longevity.

Chip Load Management

Importance of Constant Chip Load

Maintaining a constant chip load is imperative for the success of machining hardened steel. Consistent chip load ensures that the tool does not experience excessive wear or damage, leading to a more stable cutting process and superior surface finish.

Calculation of Chip Load

Accurate calculation of chip load involves considering factors such as tool diameter, cutting speed, and feed rate. By precisely determining these parameters, machinists can optimize the cutting conditions, thereby extending tool life and improving machining efficiency.

Reduced Tool Runout

Impact of Tool Runout

Tool runout, or the degree to which a tool deviates from its intended path, can have significant adverse effects on the machining process. High tool runout can lead to uneven cutting forces, accelerated tool wear, and compromised workpiece quality.

Toolholder Selection

Selecting the appropriate toolholder is crucial for minimizing tool runout. High-precision toolholders can significantly reduce runout, ensuring the tool maintains its accuracy and performance over extended periods of use. This selection, combined with proper maintenance, enhances the overall effectiveness of the machining operation.

Tool Life Management

Cutting Temperatures and Tool Life

Managing cutting temperatures is vital for prolonging tool life. Excessive heat can degrade the cutting edge, leading to premature tool failure. Monitoring and controlling temperatures during machining processes help in maintaining tool integrity and performance.

Cooling Methods

Air Jet Cooling

Air jet cooling employs a high-velocity stream of air to remove heat from the cutting zone. This method is particularly effective for applications where liquid coolants cannot be used.

Oil Mist and Air Mist

Oil mist and air mist cooling involve a fine spray of oil or air, providing lubrication and cooling simultaneously. These methods are beneficial for reducing heat buildup and enhancing tool life without the mess associated with traditional liquid coolants.

Selecting the Right Tool

Thermal Barrier Coating and Cobalt Content

Tools with thermal barrier coatings and high cobalt content are well-suited for machining hardened steel. These features provide superior heat resistance and durability, ensuring consistent performance under demanding conditions.

Negative Rake Angle Tools

Negative rake angle tools are designed to withstand the high stresses associated with cutting hardened steel. These tools effectively reduce cutting forces and improve tool life, making them a preferred choice for tough machining applications.

CBN Tooling Advantages

CBN tooling offers several advantages, including exceptional hardness and thermal stability. These tools maintain their cutting edge at high temperatures, providing excellent wear resistance and prolonged tool life. Their ability to deliver precision and efficiency in machining hardened steel makes them highly valuable in industrial applications.

Industry Applications of Hardened Steel

Hardened steel is widely utilized across various industries due to its unmatched durability and strength. In the automotive industry, it is used for manufacturing gears, axles, and other critical components that require high wear resistance. The aerospace sector relies on hardened steel for making engine parts and structural elements that must endure extreme conditions. Additionally, the tool and die industry extensively employs hardened steel for crafting molds, dies, and cutting tools, ensuring longevity and precision. Its versatility and reliability make hardened steel indispensable in construction, heavy machinery, and numerous other industrial applications.

Comparison with Other Metals

Understanding the distinct properties of hardened steel in comparison with other metals aids in selecting the right material for specific applications.

Hardened Steel vs Steel

Hardened steel differs from regular steel primarily in its hardness and strength. While standard steel offers malleability and ease of machining, hardened steel provides superior wear resistance and durability, making it suitable for applications subjected to high stresses and abrasion.

Hardened Steel vs Stainless Steel

Stainless steel is renowned for its corrosion resistance, whereas hardened steel boasts exceptional hardness. While stainless steel is preferred for applications where corrosion resistance is crucial, hardened steel is chosen for its outstanding wear and impact resistance, often in tooling and machinery.

Hardened Steel vs Exotics/HRSA’s

Exotic alloys and High-Temperature Resistant Alloys (HRSA’s) like Inconel and titanium offer unique properties such as high strength-to-weight ratios and exceptional heat resistance. However, hardened steel provides a cost-effective solution with excellent wear resistance for many industrial applications not constrained by weight or extreme temperatures.

Hardened Steel vs Cast Iron

Cast iron offers good wear resistance and is relatively inexpensive, but lacks the hardness and strength of hardened steel. Hardened steel provides superior tensile strength and durability, making it a better choice for applications requiring long-term resilience and performance.

Hardened Steel vs Aluminium

Aluminium is lightweight and easy to machine but lacks the strength and hardness of hardened steel. For applications where weight is a concern and moderate strength suffices, aluminium is chosen. However, for high-stress environments demanding superior wear resistance, hardened steel is the material of choice.

Coolant Use in Machining Hardened Steel

Coolants play a pivotal role in machining hardened steel, impacting tool life and the overall efficiency of the process.

Coolant Impact on Tool Life

The use of coolants significantly affects tool life by reducing the heat generated during machining. Efficient cooling mitigates thermal stress on the cutting tool, preventing premature wear and breakage, thus extending tool life.

Alternatives to Flood Coolant

While flood coolant is the traditional method, alternatives are gaining popularity due to their efficiency and environmental benefits.

Dry Cutting Benefits

Dry cutting eliminates the need for liquid coolants, reducing environmental impact and simplifying cleanup. With advancements in tooling technology, dry cutting can efficiently manage heat and extend tool life while maintaining machining quality.

Air or Mist Coolant

Air or mist coolants offer a balanced approach, providing sufficient cooling and lubrication without excessive fluid use. These methods enhance cutting performance and tool longevity, making them suitable alternatives to traditional coolants in machining hardened steel.

Recommended Tools for Hardened Steel

Selecting the appropriate tools is crucial for efficient machining of hardened steel, with specific recommendations for different machining processes.

Milling Tools

For milling hardened steel, tools with high-speed steel or carbide inserts are recommended. These tools offer the necessary hardness and wear resistance to handle the demanding conditions of milling operations, ensuring precision and longevity.

Turning Tools

Turning hardened steel requires tools that can withstand high stresses and temperatures. CBN inserts are highly effective, providing exceptional hardness and thermal stability, making them ideal for turning applications.

Drilling Tools

Carbide drills with specialized coatings are preferred for drilling hardened steel. These drills offer superior heat resistance and precise cutting, ensuring smooth and accurate holes without excessive wear.

Machine Taps

Machine taps designed for hardened steel utilize high-speed steel or carbide, often with advanced coatings that enhance their wear resistance and performance. These taps ensure clean, precise threading in hardened steel, optimizing both efficiency and tool life.

Further Advice and Resources

For those seeking additional information and resources on machining hardened steel, numerous industry publications, online forums, and manufacturer guidelines are available. Engaging with professional organizations and attending industry workshops can provide valuable insights and keep you updated on the latest advancements and best practices. Staying informed and continually refining your techniques will ensure success in working with hardened steel, maximizing both efficiency and performance in your projects.