Thickness gauges are essential tools in various industries, underpinning the accuracy and quality assurance of material dimensions. These precision instruments ensure the correct thickness of materials, which is pivotal for product performance and safety compliance. This article delves into the different types of thickness gauges and their industrial significance, highlighting their measurement principles and applications.

The Significance of Thickness Gauges in Industry

Importance of Thickness Gauges in the Processing Industry

In the processing industry, maintaining precise material thickness is crucial for several reasons. Firstly, it ensures the structural integrity and safety of manufactured products. Incorrect thickness can lead to material failure, potentially causing accidents and costly product recalls. Secondly, accurate measurement reduces material wastage, enhancing cost-efficiency and sustainability. Lastly, thickness gauges contribute to quality control by ensuring that products meet specified standards and regulatory requirements, thereby protecting both the manufacturer and the consumer.

Overview of Non-Destructive Testing Technology

Non-destructive testing (NDT) technology, of which thickness gauges are a part, is invaluable in modern industry. NDT methods allow for the inspection and measurement of materials and components without causing them harm. This means that products can be tested without being destroyed or altered, maintaining their usability. Thickness gauges employ various NDT techniques to measure material thickness accurately, ensuring that parts and products are safe and reliable while also saving time and resources.

Categories of Thickness Gauges

Magnetic Measurement Thickness Gauges

Magnetic measurement thickness gauges are particularly useful for measuring the thickness of ferromagnetic materials such as steel and iron. These gauges operate based on the principle of magnetic attraction, where a magnetic field is used to detect the distance between the probe and the substrate. This method is highly precise and efficient, making it suitable for industrial applications where high accuracy is paramount. Additionally, magnetic measurement thickness gauges are commonly used in the automotive and construction industries to inspect metal structures and components.

Eddy Current Measurement Thickness Gauges

Eddy current measurement thickness gauges are designed for non-ferrous metals like aluminum and copper. These gauges function by inducing eddy currents in the material through a probe. The impedance caused by the eddy currents is then measured to determine the material’s thickness. Although they offer a lower accuracy compared to magnetic measurement gauges, eddy current gauges are still highly effective for applications where non-destructive testing is required on conductive metals. Such applications include electronic components and aircraft maintenance.

Ultrasonic Measurement Thickness Gauges

Ultrasonic measurement thickness gauges use high-frequency sound waves to measure material thickness. These gauges are versatile, suitable for a wide range of materials including metals, plastics, and ceramics. Ultrasonic thickness gauges are particularly advantageous for measuring the thickness of plates, pipelines, and other processed parts. They are also extensively employed in monitoring corrosion and erosion in pipes and pressure vessels. This makes them a popular choice in industries such as oil and gas, shipbuilding, and power generation.

Principles Behind Thickness Gauge Measurement

Magnetic Measurement Principle

Suitable Materials: Steel, Iron, Silver, Nickel

Magnetic measurement thickness gauges operate based on the attraction of a magnetic probe to the material’s surface. This method is primarily suitable for ferromagnetic materials such as steel, iron, silver, and nickel. The magnetic force varies with the distance between the probe and the material, allowing for precise thickness measurements. The high sensitivity of magnetic measurement gauges ensures that even minor thickness variations can be detected, which is essential for applications demanding stringent quality control.

High Accuracy Measurement

The principle of magnetic measurement offers high accuracy, typically within a range of a few micrometers. This precision makes magnetic measurement thickness gauges ideal for applications where exact measurements are critical, such as in the manufacturing of automotive parts and heavy machinery. The significant reliability and repeatability of these gauges contribute to maintaining high standards in product manufacturing and inspection processes.

Eddy Current Measurement Principle

Suitable Materials: Conductive Metals

Eddy current measurement gauges work on the principle of electromagnetic induction, making them suitable for conductive metals such as aluminum, copper, and brass. A high-frequency alternating current is passed through a coil in the probe, generating an electromagnetic field. When brought near a conductive material, this field induces eddy currents in the material. By measuring the impedance variations caused by these currents, the gauge determines the material’s thickness.

Lower Accuracy than Magnetic Measurement

Eddy current measurement generally offers lower accuracy compared to magnetic measurement techniques. However, they are still essential for inspecting non-ferrous metals without causing damage. Despite the lower accuracy, they provide sufficient precision for various industrial applications, including aerospace and electronics, where maintaining the integrity of non-ferrous materials is crucial.

Ultrasonic Measurement Principle

Suitable for Plates and Processed Parts

Ultrasonic measurement thickness gauges use ultrasonic pulses to measure material thickness. A transducer emits ultrasonic waves that travel through the material and reflect back from the opposite surface. By measuring the time taken for the waves to return, the gauge calculates the material’s thickness. This method is particularly suited for measuring the thickness of plates, pipelines, and other processed parts, providing a non-destructive means to ensure product conformity and quality.

Monitoring Corrosion in Pipes and Pressure Vessels

One of the significant applications of ultrasonic thickness gauges is monitoring the thickness of pipes and pressure vessels, particularly in detecting corrosion and erosion. As these structures are critical to the safe operation of industrial processes, regular monitoring ensures that any deterioration is identified early and managed appropriately. This helps in preventing potential failures, guaranteeing safety and reliability in operations where corrosion could pose a serious risk.

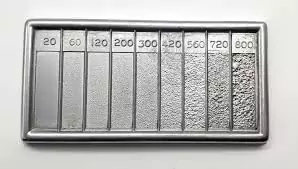

Classification of Thickness Gauges by Detection Principle

Magnetic Attraction Principle Thickness Gauge

Magnetic Attraction Thickness Gauges operate using a permanent magnet probe. This type of thickness gauge is specifically designed for use with ferromagnetic materials since it relies on the fundamental property of magnetic attraction. The probe generates a magnetic field which varies based on the gap between the probe and the material, allowing for accurate thickness measurement. An advantage of this method is it requires no external power source, simplifying its use in various environments.

Measurement Using Permanent Magnet Probe

These gauges measure the thickness by observing the strength of the magnetic field between a permanent magnet probe and the ferromagnetic material’s surface. As the distance changes, the magnetic field strength changes proportionally, enabling the technician to calculate the material’s thickness with high precision. Such reliable measurements are essential in industries where material integrity cannot be compromised.

Dependence on Magnetic Permeability Difference

The accuracy and reliability of magnetic attraction principle gauges depend significantly on the magnetic permeability difference between the base material and the coating or layer being measured. This principle makes it easiest to maintain consistent accuracy for ferromagnetic substances like iron and steel, ensuring proper material assessment for construction, manufacturing, and maintenance applications.

Magnetic Induction Principle Thickness Gauge

Magnetic Induction Thickness Gauges offer another non-contact method for measuring material thickness, particularly focusing on ferromagnetic materials. These gauges leverage magnetic flux to derive thickness values, a principle that ensures high accuracy and repeatability.

Magnetic Flux Measurement

In magnetic induction thickness gauges, an alternating magnetic field is generated within the probe which passes through the ferromagnetic material. The thickness of the material alters the magnetic field, and this change is measured as magnetic flux. By interpreting the variations in magnetic flux, the gauge calculates the thickness with precision.

Influence of Magnetic Flux on Induced Electromotive Force

The principle also involves measuring the electromotive force (EMF) induced by the changing magnetic field as it interacts with the material. Essentially, the magnetic flux alterations create an EMF whose magnitude is inversely proportional to the material’s thickness. These calculations are processed to deliver accurate thickness readings, ensuring material usability and compliance with industry standards.

Eddy Current Measurement Thickness Gauge

Eddy Current Thickness Gauges apply the principle of electromagnetic induction but differ in their approach compared to magnetic induction gauges. These are designed for non-ferromagnetic and conductive materials, distinguishing them from magnetic-based technologies.

High-Frequency Alternating Current and Electromagnetic Field

In eddy current thickness gauges, a high-frequency alternating current (AC) passes through the coil within the gauge’s probe, generating an electromagnetic field. When this electromagnetic field encounters a conductive material, it induces eddy currents. The impedance caused by these eddy currents is influenced by the material’s thickness, thus offering a non-destructive way to measure thickness.

Measurement of Distance Using Eddy Current Feedback

The feedback from eddy currents provides vital information about the distance between the probe and the material, essentially informing the thickness gauge about the material’s thickness. The induced eddy currents generate measurable impedance variations proportional to material thickness, enabling precise assessments over a range of applications such as in aerospace and marine environments, where non-ferrous material integrity is crucial.

Technological Advancements in Thickness Gauges

Improved Probe Structure and Microcomputer Technology

Technological advancements have significantly enhanced the functionality and user experience of thickness gauges. Modern gauges benefit from improved probe structures, resulting in better accuracy and adaptability to various materials and conditions. Moreover, the integration of microcomputer technology has facilitated advanced data processing capabilities. These developments allow for real-time measurements, data storage, and analysis, leading to more efficient and effective thickness measurement procedures in industrial applications.

Automatic Probe Identification and Control Programs

Another significant advancement is the introduction of automatic probe identification systems and control programs. These systems automatically recognize the type of probe connected and adjust the gauge’s settings accordingly. This feature not only simplifies the operation but also minimizes human error, ensuring consistent and reliable results. The automatic control programs can also optimize the measurement process by adjusting parameters to match the specific requirements of different materials and applications.

Multi-Probe Connection Capabilities

Modern thickness gauges also offer multi-probe connection capabilities, allowing multiple probes to be connected and used simultaneously. This advancement is particularly beneficial in complex industrial settings where different types of measurements are required. By enabling the use of various probes with a single device, these advanced thickness gauges enhance flexibility and efficiency, saving time and resources. The ability to switch between probes seamlessly ensures that the most appropriate measurement technique is applied to each task, improving overall accuracy and reliability.

Detailed Look at Ultrasonic Thickness Gauge Technology

Ultrasonic Pulse Reflection Principle

Ultrasonic thickness gauges operate on the principle of ultrasonic pulse reflection. A transducer emits ultrasonic pulses that travel through the material being measured. These pulses reflect off the back surface of the material and return to the transducer. By measuring the time it takes for the pulses to travel to the back surface and return, the gauge calculates the material’s thickness. This non-destructive testing method is suitable for a wide range of materials, providing reliable and accurate thickness measurements.

Measurement of Ultrasonic Propagation Time

The key to the accuracy of ultrasonic thickness gauges lies in the precise measurement of ultrasonic propagation time. The gauge calculates the material thickness based on the known speed of sound in the material and the time measured for the pulses to travel through it. This method allows for high-precision measurements, even for thin or corroded materials. The capability to measure thickness without damaging the material makes ultrasonic thickness gauges invaluable in industries where material integrity is critical, such as aerospace, automotive, and manufacturing.

Calibration Procedures for Thickness Gauges

Selection of Measuring Points and Standard Materials

Proper calibration is crucial for ensuring the accuracy and reliability of thickness gauges. The first step in the calibration process is the selection of appropriate measuring points and standard materials. Calibration points should be chosen based on the specific application and material properties. Standard materials with known thicknesses are used as references to calibrate the gauge. This ensures that the measurements taken by the thickness gauge are accurate and consistent with industry standards.

Common Operational Considerations

Lower Limit on Surface Curvature and Minimum Thickness

When operating thickness gauges, it is essential to consider the lower limit on surface curvature and minimum thickness. Highly curved surfaces can pose challenges for accurate measurement, as the probe may not make uniform contact with the material. Similarly, materials with thicknesses below the gauge’s minimum threshold may produce unreliable readings. Understanding these limitations helps in selecting the appropriate gauge and probe for the task, ensuring accurate measurements and preventing erroneous data.

Probe Orientation and Pressure

The orientation and pressure applied to the probe also play a critical role in obtaining accurate measurements. The probe should be positioned perpendicular to the material’s surface to ensure consistent contact and accurate readings. Applying consistent and appropriate pressure helps maintain good contact between the probe and the material, reducing the risk of measurement errors. Proper training and awareness of these factors are essential for operators to achieve reliable and accurate results.

Interference from External Magnetic Fields

External magnetic fields can interfere with the operation of thickness gauges, particularly those based on magnetic measurement principles. It is important to minimize or eliminate sources of external magnetic interference during measurements. This may involve conducting measurements in a controlled environment or using shielding to block unwanted magnetic fields. By addressing potential sources of interference, operators can ensure the integrity of their measurements and obtain reliable data.

Influence of Temperature and Coupling Agent Viscosity

Temperature variations and the viscosity of coupling agents can also impact measurement accuracy. Thickness gauges should be calibrated and operated within the recommended temperature range to ensure consistent readings. Additionally, the viscosity of coupling agents used in ultrasonic thickness measurement can affect the transmission of ultrasonic pulses. Selecting the appropriate coupling agent and maintaining consistent application conditions are important for obtaining accurate measurements. Proper handling of these factors ensures that the thickness gauge provides reliable and repeatable results under varying conditions.

Synopsis of Investigated Principles and Developments

In summary, thickness gauges are indispensable tools across various industries, providing precise and reliable measurements essential for quality control, safety compliance, and material integrity. The principles behind their operation—magnetic measurement, eddy current measurement, and ultrasonic measurement—each offer unique advantages for different applications and materials. Recent technological advancements, such as improved probe structures, automatic probe identification, and multi-probe connection capabilities, have enhanced the functionality and versatility of thickness gauges, making them more efficient and user-friendly.

Understanding the underlying principles and proper calibration procedures is crucial for maximizing the accuracy and reliability of thickness gauges. By selecting the appropriate type of gauge, considering operational factors, and staying informed about technological developments, industries can ensure that their materials and products meet the highest standards of quality and safety.