The Role of Precision Measurement Tools in Metalworking

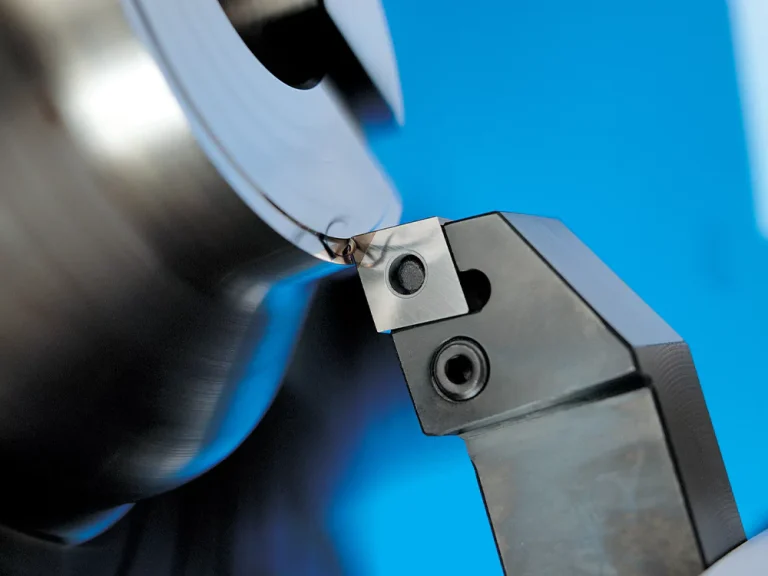

Importance of Precision Measurement Tools in Metalworking

Precision measurement tools are indispensable in the field of metalworking. These instruments ensure that components meet exact specifications, reducing errors and improving product quality. Accurate measurements are critical in industries such as automotive, aerospace, and manufacturing, where even minor deviations can lead to significant issues. Investing in precision tools not only enhances accuracy but also boosts efficiency, ensuring products meet stringent standards. Companies adept in utilizing precision measurement tools often lead their fields due to their commitment to quality and reliability.

Types of Precision Measurement Tools

Analog (Mechanical Readout)

Analog measurement tools have been stalwarts in metalworking for decades. Known for their simplicity and durability, these mechanical instruments provide precise readings without the need for batteries or electronic components. They are ideal for environments where electronic interference could be an issue or in situations where ruggedness is paramount. Analog tools are often preferred for their tactile feedback and the ability to make incremental adjustments manually.

Electronic (Digital Readout)

Electronic measurement tools feature digital readouts, making it easier to read measurements without any guesswork. With their ability to store data and interface with computers, these tools enhance efficiency and accuracy. Digital tools can perform functions such as data logging and complex calculations, which simplifies tasks that would be time-consuming with traditional methods. Their precision and ease of use make them popular choices in modern metalworking environments.

Wireless Electronic Tools

Wireless electronic measurement tools represent the cutting edge in precision measurement. By eliminating cables, these tools offer greater flexibility and mobility. Data can be transmitted in real-time to a central system, enabling instant analysis and decision-making. This is particularly useful in large manufacturing operations where efficiency and quick adjustments are crucial. Wireless tools reduce the risk of tripping on cables and simplify the workspace, streamlining operations further.

Key Requirements for Quality Control

Statistical Process Control (SPC)

Statistical Process Control (SPC) is a method of quality control that uses statistical methods to monitor and control a process. It is essential in metalworking to ensure processes remain within predetermined limits. By using SPC, manufacturers can detect and correct variations in the manufacturing process before they result in defective products. This proactive approach to quality control minimizes waste and enhances consistency in production.

Measurement Documentation

Accurate measurement documentation is critical in maintaining quality standards. It involves recording all measurements taken during the manufacturing process to ensure traceability and accountability. Proper documentation helps identify trends, track performance, and provide a historical record in case of product failures. This practice is vital for compliance with industry regulations and for continuous improvement initiatives.

Micrometers

Overview of Micrometers

Micrometers are precision tools used to measure small distances with high accuracy. They are a staple in metalworking for tasks requiring exact measurements, such as the thickness of materials or the diameter of small parts. With their ability to measure dimensions down to the micrometer level, these tools ensure every component fits correctly and functions as intended.

Accuracy and Applications

The accuracy of micrometers is typically within one-thousandth of an inch (0.001 inches) or one-hundredth of a millimeter (0.01 mm). This exceptional level of precision makes micrometers indispensable in industries where exact measurements are critical. Applications range from manufacturing and engineering to quality inspection and scientific research. The ability to achieve consistent, repeatable results is a major advantage of using micrometers.

Types of Micrometers

Outside Micrometers

Outside micrometers, or external micrometers, are designed to measure the outside dimensions of an object. They are widely used in metalworking to gauge the width, thickness, and diameter of parts. These micrometers feature a screw mechanism that advances the spindle towards the anvil, allowing for precise measurement of the external surfaces of various components.

Inside Micrometers

Inside micrometers are used to measure the internal dimensions of an object, such as the diameter of a hole or the distance between two internal surfaces. These tools are essential for ensuring that drilled holes and other internal features meet specified tolerances. The ability to accurately measure internal dimensions is crucial for the proper assembly and function of many mechanical parts.

Disc Micrometers

Disc micrometers have disc-shaped anvils and spindles, making them ideal for measuring the thickness of materials such as paper, rubber, and plastics. These specialized micrometers offer precision in applications where standard micrometer anvils may not fit or provide accurate readings. Industries utilizing thin materials often rely on disc micrometers for their specific measurement needs.

Blade Micrometers

Blade micrometers feature narrow, blade-like anvils and spindles, making them suitable for measuring small grooves, slots, or keyways. They provide excellent accuracy in places where conventional micrometer anvils would be too large to fit. The ability to measure small, intricate features makes blade micrometers valuable tools in precision engineering and manufacturing.

Features of Micrometers

Mechanical Micrometers

Mechanical micrometers operate using a screw mechanism to provide highly accurate measurements. They offer tactile feedback, making them preferred by users who require a manual and methodical approach. These micrometers are incredibly reliable and do not rely on batteries, making them suitable for environments where electronic tools may be compromised.

Electronic Micrometers

Electronic micrometers integrate digital displays, providing clear and easy-to-read measurements. They can store measurement data and perform additional functions such as metric/imperial conversion. The digital readout eliminates human error associated with reading analog scales, enhancing precision and efficiency during measurement tasks.

Wireless Micrometers

Wireless micrometers transmit measurement data to computers or other devices in real-time, facilitating immediate analysis and documentation. This capability streamlines workflows and reduces the need for manual recording, ensuring higher accuracy and productivity. Wireless micrometers are ideal for modern manufacturing environments where data integration and connectivity are essential.

IP67 Compliant Models

IP67 compliant micrometers are designed to withstand harsh industrial environments. These models are dustproof and can withstand temporary immersion in water, making them suitable for use in conditions where exposure to dust, coolant, or other contaminants is common. Their robust construction ensures long-term durability and reliable performance even under adverse conditions.

Usage in Harsh Environments

Protection Against Coolant, Water, Oils, Dirt, Dust, and Mist

Micrometers used in harsh environments must be designed to resist various contaminants. Protection against coolant, water, oils, dirt, dust, and mist is essential to maintain accuracy and extend the tool’s lifespan. Features such as seals, gaskets, and anti-corrosion coatings are commonly employed to safeguard the instrument. IP67 compliance further ensures that micrometers can operate reliably in demanding conditions, making them indispensable tools for industrial applications. Regular maintenance and proper storage are also vital practices to ensure the longevity and functionality of these precision instruments.

Slide Calipers

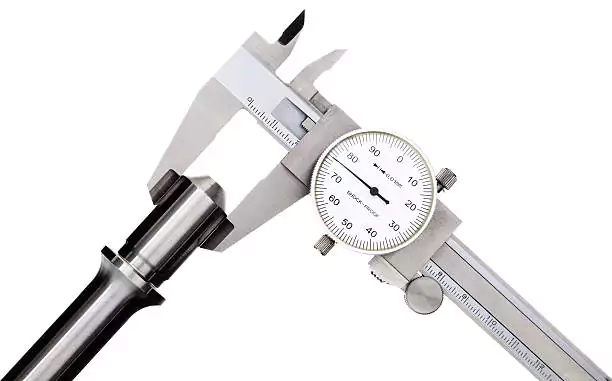

Overview of Slide Calipers

Slide calipers are versatile measurement tools that are widely used in the metalworking industry. These instruments allow for the measurement of internal and external dimensions, as well as depths. Their ability to provide quick and accurate measurements makes them invaluable in settings where speed and precision are critical. Slide calipers are commonly used for quality control, inspection, and production processes, ensuring that parts meet strict tolerances.

Measurement Range and Flexibility

Slide calipers typically offer a broad measurement range, from a few millimeters to several hundred millimeters. This flexibility allows them to be used for a variety of applications, from measuring small components to larger assemblies. The broad range of calipers available means there is a suitable tool for nearly every measurement task. The ease of use and adaptability make slide calipers essential tools for anyone involved in precise measurement.

Types of Slide Calipers

Electronic Slide Calipers

Electronic slide calipers feature digital displays that make it easy to read measurements with minimal error. These calipers often include functions such as data hold, incremental measurement, and metric/imperial conversion. The digital readout improves accuracy and reduces the possibility of misreading measurements, enhancing efficiency in the workplace. Electronic slide calipers are ideal for modern manufacturing environments where precision and speed are critical.

Dial Calipers

Dial calipers utilize a mechanical dial to display measurements. They offer high precision and are appreciated for their ease of use and reliability. The dial provides a clear visual representation of measurements, which can be easier to interpret than a vernier scale. Dial calipers are durable and do not require batteries, making them a dependable choice in various industrial settings.

Vernier Scale Calipers

Vernier scale calipers are traditional tools that utilize a sliding scale for measurements. They require the user to read two scales – the main scale and the vernier scale – to determine the measurement. While they can be more challenging to read than digital or dial calipers, they offer high precision and do not rely on electronic components. Vernier calipers are often used in environments where ruggedness and simplicity are paramount.

Features and Variations

Common Sizes (6”/150mm, 8”/200mm, 12”/300mm)

Slide calipers are available in various sizes to accommodate different measurement needs. Common sizes include 6 inches (150 mm), 8 inches (200 mm), and 12 inches (300 mm). The size of the caliper dictates its maximum measurement capacity, with larger calipers providing greater range. Choosing the appropriate size ensures that measurements can be taken accurately and efficiently.

Carbon Fiber Models

Carbon fiber slide calipers are designed to be lightweight yet strong. They are ideal for applications where ease of handling and reduced weight are important, such as in repetitive measurement tasks. Carbon fiber calipers offer the additional benefits of being non-magnetic and resistant to corrosion, making them suitable for use in various industrial environments. Their durability and precision make them a valuable addition to any measurement toolkit.

Specialized Tools (Long Jaws, Alternative Contacts)

Specialized slide calipers are available to address specific measurement challenges. Long jaw calipers, for example, allow for the measurement of larger or awkwardly shaped objects. Alternative contact calipers can be used to measure difficult-to-access features or materials with unique properties. These specialized tools enhance the versatility and utility of slide calipers, enabling accurate measurements in a wide range of applications.

Custom Built Slide Calipers

Custom built slide calipers can be designed to meet specific measurement requirements that standard tools cannot address. This customization can include unique jaw shapes, extended measurement ranges, or specialized materials. By tailoring the caliper to the specific needs of the application, users can achieve greater efficiency and accuracy in their measurement tasks. Custom calipers are ideal for specialized industries and applications where standard tools fall short.

Wireless Models

Wireless slide calipers incorporate technology that allows measurement data to be transmitted directly to a computer or data collection system. This capability enables real-time data analysis and improves workflow efficiency by reducing the need for manual data entry. Wireless models are particularly useful in environments where data integration and connectivity are critical. They enhance productivity and minimize the risk of errors associated with manual recording.

Height Gages

Overview of Height Gages

Height gages are precision instruments used to measure vertical distances or heights. They play a crucial role in quality control and inspection processes, ensuring that components meet specified height tolerances. Height gages are widely used in metalworking, machining, and metrology applications. Their ability to provide accurate height measurements is essential for ensuring the proper alignment and fit of parts.

Function and Accuracy

Height gages function by moving a measurement probe along a vertical column and reading the position on a scale or digital display. The accuracy of height gages can be within a few micrometers, making them suitable for high-precision applications. These tools are essential for tasks that require precise measurement of dimensions such as the height of a workpiece, the depth of a slot, or the distance between features. The high accuracy of height gages ensures consistent and reliable measurements.

Components of Height Gages

Scriber

The scriber is a pointed tool attached to the height gage, used for scribing lines or points on a workpiece. It ensures that measurement markings are highly accurate, enabling precise layout work. The scriber is typically made from hardened steel or carbide to maintain sharpness and durability. Accurate scribing is critical for ensuring that subsequent machining processes are aligned correctly.

Test Indicator

A test indicator can be attached to a height gage to measure slight deviations or runout in a component’s surface. The indicator enhances the gage’s versatility, allowing it to perform additional measurement tasks beyond basic height measurement. Test indicators are sensitive to small changes in position, providing precise readings that are essential for high-accuracy applications.

Touch Probe

Touch probes are used in height gages to contact the surface of a workpiece and register precise height measurements. They are often employed in automated measurement systems, where they can quickly and accurately capture data. The touch probe minimizes human error and ensures consistent measurement results, making it ideal for quality control processes.

CMM-style Probe

CMM-style probes (Coordinate Measuring Machine probes) combine the features of traditional touch probes with advanced sensors to provide highly accurate measurements. These probes can capture data points in three dimensions, offering a comprehensive analysis of a workpiece’s geometry. The use of CMM-style probes in height gages enhances their functionality and precision, making them suitable for complex measurement tasks.

Depth Gages

Overview of Depth Gages

Depth gages are specialized tools used to measure the depth of holes, slots, and recesses. They are essential for ensuring that machined features meet specified depth tolerances. Depth gages are widely used in metalworking, machining, and quality control applications. Their ability to provide precise depth measurements ensures that components are manufactured to exact specifications.

Function and Applications

Depth gages function by positioning a measurement probe or base against a reference surface and measuring the depth to a specific point. Applications of depth gages include measuring the depth of drilled holes, slots, and counterbores, as well as the height of steps and shoulders. Accurate depth measurements are critical for ensuring the proper assembly and performance of components in various industries.

Types of Depth Gages

Depth Micrometers (Electronic, Dial, Vernier)

Depth micrometers are precision tools designed to measure depth with high accuracy. They come in electronic, dial, and vernier versions, each offering different features and levels of precision. Electronic depth micrometers provide digital readouts for easy and accurate measurement. Dial depth micrometers offer clear visual readings through a mechanical dial. Vernier depth micrometers use a sliding scale for traditional, high-precision measurements. Each type serves specific needs and preferences in the metalworking industry.

Rule Gages

Rule gages are simple depth measurement tools that use a graduated scale to measure depth. They are easy to use and provide quick measurements, making them suitable for general-purpose depth measurement tasks. While they may not offer the same level of precision as micrometers or electronic gages, rule gages are valuable for their simplicity and ease of use.

Combination Rule Gages

Combination rule gages incorporate multiple measurement functions into a single tool. These gages can measure depth, height, and sometimes even angle, making them versatile and convenient for a variety of tasks. Combination rule gages are ideal for applications requiring multiple types of measurements, reducing the need for multiple tools and streamlining the measurement process.

Bore Gages

Overview of Bore Gages

Bore gages are precision instruments used to measure the internal diameter of cylindrical objects such as pipes, tubes, and machined holes. They are essential for ensuring that these features meet specified tolerances and are correctly sized. Bore gages are widely used in industries such as manufacturing, automotive, and aerospace, where precise internal measurements are critical.

Function and Applications

Bore gages function by expanding inside a hole to measure its internal diameter. They provide highly accurate measurements, making them indispensable for quality control and inspection processes. Applications of bore gages include checking the diameter of drilled or bored holes, measuring the wear and ovality of cylinders, and verifying the dimensions of precision parts. Accurate bore measurements are essential for ensuring the proper fit and function of components in various assemblies.

Types of Bore Gages

Wireless Bore Gages

Wireless bore gages incorporate technology that allows measurement data to be transmitted wirelessly to a computer or data collection system. This feature enhances workflow efficiency by reducing the need for manual data entry and enabling real-time data analysis. Wireless bore gages are ideal for modern manufacturing environments where data integration and connectivity are critical. They improve productivity and reduce the risk of errors associated with manual recording.

IP67 Compliant Models

IP67 compliant bore gages are designed to withstand harsh industrial environments. These models are dustproof and can withstand temporary immersion in water, making them suitable for use in conditions where exposure to dust, coolant, or other contaminants is common. Their robust construction ensures long-term durability and reliable performance even under adverse conditions. IP67 compliant bore gages are essential for maintaining accuracy in demanding industrial applications.

Indicators and Gages

Overview of Indicators and Gages

Indicators and gages are essential tools used to measure and compare dimensions in metalworking and other precision industries. They play a critical role in quality control, ensuring that parts meet specified tolerances and are free from defects. Indicators and gages are used in a variety of applications, from checking the flatness and alignment of surfaces to measuring the runout and concentricity of rotating parts. Their ability to provide accurate and repeatable measurements makes them indispensable in precision manufacturing.

Major Classes of Gages

The major classes of gages include fixed gages, such as plug and ring gages, and adjustable gages, such as snap and thread gages. Fixed gages are used to check specific dimensions or tolerances, offering a quick and reliable pass/fail assessment. Adjustable gages can be set to measure a range of dimensions, providing greater flexibility in the measurement process. Both types of gages are essential for ensuring that parts conform to specified standards.

Types of Indicators

Mechanical Dial Indicators

Mechanical dial indicators use a plunger mechanism to translate linear movement into rotational movement on a dial. They provide high-precision measurements and are widely used for tasks such as checking the flatness, alignment, and runout of surfaces. The dial provides a clear visual representation of measurements, making it easy to interpret the results. Mechanical dial indicators are durable and reliable, making them a staple in many industrial applications.

Electronic Display Indicators

Electronic display indicators feature digital readouts, providing clear and easy-to-read measurements. They offer high precision and can include additional functions such as data hold, preset values, and metric/imperial conversion. Electronic indicators eliminate reading errors associated with mechanical dials and enhance efficiency in measurement tasks. They are ideal for modern manufacturing environments where precision and speed are essential.

Lever Style Test Indicators

Lever style test indicators use a lever mechanism to measure small deflections or deviations in a surface. They are highly sensitive and provide precise measurements, making them suitable for tasks such as checking the flatness and parallelism of surfaces. The lever mechanism allows the indicator to access hard-to-reach areas, enhancing its versatility. Lever style test indicators are commonly used in inspection and quality control processes.

Back Plunger Indicators

Back plunger indicators have a plunger mechanism located at the back of the tool, allowing for measurements in tight or confined spaces. They are ideal for tasks where conventional indicators cannot fit or provide accurate readings. The back plunger design ensures that measurements can be taken from different angles, making these indicators versatile and useful in various applications. Their precision and compact design make them valuable tools in precision manufacturing.

Applications and Requirements

Checking Run-Out

Indicators and gages are commonly used to check the run-out of rotating parts, ensuring that they are concentric and free from wobbling. Accurate run-out measurements are essential for maintaining the performance and longevity.

Hardness and Surface Testers

Overview of Hardness Testers

Hardness testers play a critical role in evaluating the resistance of materials to deformation. These tools are essential in ensuring the durability and quality of materials in industries such as automotive, aerospace, and construction. Hardness measurement is often a predictor of a material’s performance, reliability, and wear resistance.

Function and Applications

Hardness testers function by applying a specific force to an indenter, pressing it into the material’s surface, and measuring the depth or size of the indentation. This data helps in determining the hardness level, which is crucial for selecting the right materials for different applications. For example, in the automotive industry, ensuring that parts meet hardness specifications prevents premature wear and failure.

Types of Hardness Testers

There are several types of hardness testers, each designed for specific testing environments and material types:

- Analog and Digital Bench Solutions: These are typically stationary units used in laboratories or testing facilities. They provide high precision and are often used for quality control in manufacturing environments.

- Portable Versions: These testers are designed for on-site testing and are ideal for large structures or immovable objects. They offer flexibility and the capability to test materials in their actual usage locations.

- Shore Portable Hardness Testers: Primarily used for measuring the hardness of softer materials like rubber or plastics, these tools are portable and easy to use, providing quick and reliable readings.

- Electronic Durometers: These advanced devices offer digital readouts and enhanced precision, suitable for various industrial applications. They often come with data storage capabilities, making it easier to track and analyze test results over time.

Ultrasonic Thickness Gages

Ultrasonic thickness gages are indispensable for measuring the thickness of materials without destroying them. They use ultrasonic waves to gauge thickness, which is crucial in industries where material integrity and thickness uniformity are vital, such as in metal fabrication and pipeline maintenance.

Coating Thickness Gages

These tools measure the thickness of coatings applied to surfaces, ensuring that they meet specified thickness standards. Coating thickness gages are widely used in automotive, aerospace, and manufacturing industries to verify the quality of paint and other protective coatings.

Surface Roughness Testers

Surface roughness testers assess the texture of a surface, which is important for determining how a material will interact with other surfaces and its performance under different conditions. These testers are used in fields like metalworking, where the surface finish can significantly impact the functionality and lifespan of a part.

Data Collection Systems

Overview of Data Collection Systems

In the age of the Internet of Things (IoT) and Industry 4.0, data collection systems have become indispensable. They facilitate the real-time collection, analysis, and storage of data from various measurement tools, enhancing accuracy and efficiency in manufacturing processes.

Importance in IoT and Industry 4.0

Data collection systems are the backbone of smart manufacturing environments. By integrating these systems, industries can monitor processes in real-time, make data-driven decisions, and quickly adapt to changing conditions. This capability is fundamental to the automation and continuous improvement paradigms of Industry 4.0.

Features of Data Collection Systems

Modern data collection systems come equipped with various features that enhance their functionality:

- Wireless and Mobile Retrieval: These systems support wireless connectivity, allowing data to be collected and accessed remotely. This feature is particularly beneficial in large manufacturing plants where manual data collection would be inefficient.

- Robustness and Encryption: Ensuring data integrity and security is crucial. Advanced data collection systems provide robust encryption protocols to protect sensitive information from unauthorized access.

- Gage Compatibility: Compatibility with a wide range of gages and measurement tools ensures that data can be collected from various sources, providing a comprehensive overview of the manufacturing process.

Squares and Precision Rulers, Straight Edges & Parallel

Overview of Squares and Precision Rulers

Squares and precision rulers are fundamental tools in any precision work. They help maintain accuracy in measurements and alignments, playing a pivotal role in tasks that demand exactness, such as in carpentry, metalworking, and machining.

Function and Applications

Squares ensure that angles are exact, which is crucial in constructing perfectly aligned parts or assemblies. Precision rulers and straight edges are used for measuring and verifying the straightness of lines and surfaces. These tools are indispensable in ensuring that components meet the required specifications and fit together correctly.

Types of Squares and Rulers

There are several types of squares and precision rulers, each suited for specific tasks:

- Combination Squares: These versatile tools can measure and check angles, depths, and center points. They are commonly used in woodworking, metalworking, and other trades where precision is essential.

- Steel Precision Rules: Made from high-quality steel, these rulers provide accurate measurements and are essential in technical fields for marking and measuring materials.

- Steel Straight Edges: Used to check the flatness of surfaces, steel straight edges are critical in ensuring components meet flatness specifications.

- Steel Parallels: These tools are used to set up workpieces accurately in machinery, ensuring that they are positioned correctly for drilling, milling, or other machining operations.

Protractors and Angle Measurements

Overview of Protractors

Protractors are tools designed for measuring and laying out angles precisely. They are crucial in various fields, including carpentry, metalworking, and engineering, where accurate angle measurements are necessary for the creation of parts and assemblies.

Function and Applications

Protractors function by providing a scale for measuring angles, which can range from simple to complex geometries. They are essential for tasks such as drafting, model making, and machining, where precise angle measurements ensure the proper fit and function of parts.

Types of Protractors

- Graduated Scales with Movable Blade: This type of protractor includes a blade that can be adjusted to measure various angles. It’s versatile and is often used in drafting and layout work.

- Bevel Protractors: These are more advanced protractors with a vernier scale, allowing for very precise angle measurements. They are often used in machining and metalworking where high precision is required.

- Protractor/Depth Gages: These dual-function tools can measure both angles and depths, making them versatile for a range of applications from woodworking to metalworking.

- Special Drill Point Gages: Specifically designed for checking the angle and lip clearance of drill points, these gages ensure that drills function properly and produce accurate holes.

Machinist Precision Levels

Overview of Machinist Precision Levels

Machinist precision levels are devices used to ascertain and maintain level surfaces in various industrial settings. They are designed to be highly accurate and are crucial in the setup and calibration of machinery and equipment.

Function and Applications

These levels ensure that machinery is set up correctly, which is crucial for achieving precision in manufacturing processes. They are used in metalworking, aerospace, and automotive industries where even the slightest deviation can lead to significant errors in production.

Importance of Levelness in Machinery Setup

Ensuring machinery is level is fundamental for operational efficiency and product quality. A level setup prevents issues such as improper alignment, uneven wear of parts, and inaccuracies in machining. This importance is magnified in industries where precision is of utmost priority, like aerospace or high-performance automotive sectors.

Fixed Gage Standards

Overview of Fixed Gage Standards

Fixed gage standards are tools used to measure and verify specific dimensions in manufacturing processes. They ensure that parts and components meet stringent specifications and are critical for maintaining quality control.

Function and Applications

These gages function as reference standards against which part dimensions are measured. They are widely used in industries like automotive, aerospace, and precision engineering to verify the dimensions of manufactured parts and ensure they comply with design specifications.

Types of Fixed Gages

- Pin Gages: These are cylindrical gages used to measure hole diameters. They ensure that drilled or machined holes are within tolerance.

- Drill Gages: Used to measure the diameter of drill bits, these gages help in verifying tool sizes and ensuring correct hole dimensions.

- Sheet and Wire Gages: These measure the thickness of sheets and wires. They are crucial in industries where material thickness affects product quality, such as metalworking and electrical manufacturing.

- Center Gages: Used in lathe work for checking the angles of thread cutting tools, ensuring accurate threading operations.

- Screw Pitch Gages: These gages measure the pitch or lead of screws, ensuring that threaded parts mate correctly and securely.

- Radius Gages: Employed to check the radius of curves, these gages are vital in ensuring parts meet design specifications for rounded edges.

- Ball and Diameter Gages: These measure the diameter of balls and similar objects, crucial in quality control for bearings and other spherical components.

- Angle Gages: Used to measure specific angles, these gages ensure components meet precise angular specifications.

- Thickness Gages: Also known as feeler gages, these measure gap widths or thicknesses of narrow spaces, ensuring components fit and function correctly.

- Feeler Stock: These are thin gage strips used to measure gap dimensions, playing a key role in activities like engine assembly where precision is critical.

Dividers, Calipers, Trammels

Overview of Dividers, Calipers, and Trammels

These tools are foundational in precision measurement and layout tasks. Used across multiple industries, they are vital in ensuring that distances and dimensions are accurately measured and transferred.

Function and Applications

Dividers and calipers are primarily used for measuring and setting distances, while trammels are used for drawing large circles or arcs. These tools are indispensable in tasks that require meticulous precision, such as in aviation, automotive, and metalworking industries.

Types of Dividers

- Measuring and Transferring Distances: Dividers are used to measure and transfer precise distances. This function is essential in tasks where dimensions must be replicated accurately across different parts or materials.

Types of Trammels

- Layout and Scribing Circles: Trammels, equipped with adjustable points, are used to layout and scribe large circles or arcs. They are particularly useful in metalworking and carpentry for marking out shapes on large surfaces.

- Measuring Distances and Circles: Trammels also serve to measure large distances or the diameter of large circles. Their versatility makes them valuable in various industrial applications.

Other Precision Shop Tools

Overview of Other Precision Shop Tools

Beyond the commonly known tools, there are various other precision shop tools that play a critical role in ensuring quality and accuracy in manufacturing and engineering tasks. These tools aid in positioning, marking, and holding workpieces during manufacturing processes.

Function and Applications

These tools are essential for setting up workpieces, marking measurements, and maintaining the position of materials during machining and assembly. Their correct use ensures that the manufacturing process runs smoothly and that the final product meets all design specifications.

Types of Other Tools

- Work Positioning Tools: Tools like vises and clamps hold workpieces securely in place during manufacturing processes, ensuring stability and precision.

- Scribes: Used to mark lines on workpieces, scribes are essential in layout tasks, ensuring that cutting and machining operations are carried out accurately.

- Punches: These tools are used to mark positions for drilling and to drive pins or create indentation points on workpieces, which guides further machining processes.

- Vises: Critical for holding workpieces steady during machining, vises ensure that parts do not move, maintaining precision and quality.

- Layout Die Lubricant: Applied to workpieces before scribing, this lubricant ensures that lines are clearly visible and accurately marked, facilitating precise machining and fabrication processes.

Understanding the vast array of measurement tools available and their specific applications is critical for anyone involved in precision work. Accurate measurements are fundamental to quality control, and the appropriate use of these tools ensures that products meet stringent specifications and perform reliably in their intended applications. This primer serves as a comprehensive guide for beginners, helping them grasp the importance and functions of various measurement tools used across diverse industries.