Understanding Measuring Instruments

Overview of Measuring Instruments

Measuring instruments are vital tools in various industries, ranging from manufacturing and engineering to science and technology. They ensure precision and accuracy in the measurement of physical quantities, which is crucial for maintaining quality and consistency in production processes. These instruments come in many forms, each designed for specific tasks. Understanding their differences and applications can significantly enhance efficiency and productivity in workshops and laboratories.

Importance in Workshops

In workshops, the role of measuring instruments cannot be understated. They are essential for crafting components that meet exact specifications. Without accurate measurements, parts may not fit together correctly, leading to product failures and increased costs due to wasted materials and time. Calipers and micrometers, in particular, are two of the most commonly used tools in this setting, each offering unique advantages and catering to different measurement needs.

Exploring Calipers

Definition and Function

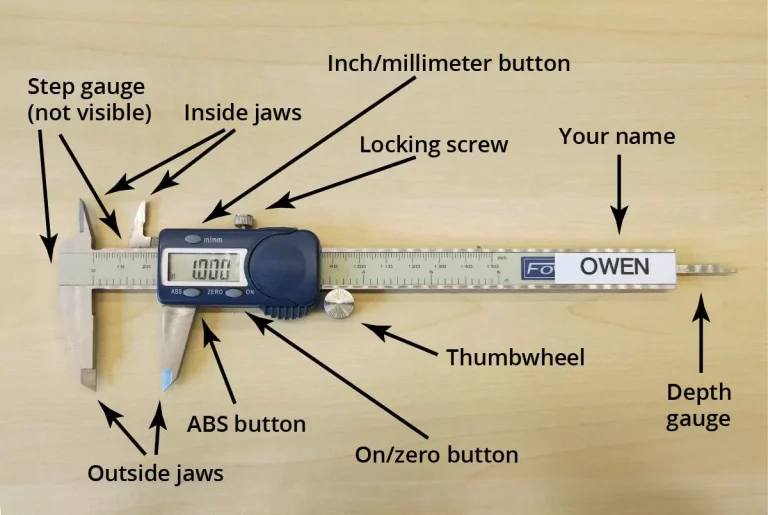

Calipers are measuring tools used to determine the distance between two opposite sides of an object. They are fundamental instruments in any workshop or laboratory, facilitating the measurement of length, width, and depth. Calipers can measure the external and internal dimensions of objects with a fair degree of accuracy, making them versatile tools in various applications.

Measuring Length, Width, and Depth

One of the primary functions of calipers is to measure the length, width, and depth of an object accurately. They come equipped with two sets of jaws: one to measure external dimensions and the other for internal dimensions. Additionally, a depth probe allows users to measure the distance from the edge to the bottom of a recess. This multifunctionality makes calipers indispensable in settings where a range of precise measurements is required.

Types of Calipers

Calipers come in several types, each suited to different measurement tasks and offering varying degrees of accuracy and ease of use.

Analogue or Vernier Calipers

Analogue or Vernier calipers are traditional calipers that feature a main scale and a sliding Vernier scale. These calipers require manual reading of measurements, which can be challenging for some users. However, they are highly reliable and require no batteries, making them a durable and cost-effective choice.

Digital Calipers

Digital calipers are advanced versions that display measurements on an electronic screen, making them easier to read and use. They often come with additional features such as data hold, inch/metric conversion, and zero setting. Their precision and ease of use make them popular in modern workshops, although they require batteries and can be more expensive than Vernier calipers.

Dial Calipers

Dial calipers use a dial gauge to display measurements, combining the simplicity of an analogue readout with the ease of a digital display. The dial caliper’s gear-train mechanism converts the linear motion of the caliper jaws into rotary dial movement, providing precise readings. These calipers are suitable for users who prefer a mechanical display but require greater accuracy than standard Vernier calipers.

In conclusion, while calipers—whether analogue, digital, or dial—offer a versatile range of measurement options, understanding their specific types and functionalities can significantly enhance the efficiency and accuracy of measurement tasks in workshops and laboratories.

Unveiling Micrometers

Definition and Function

Micrometers are precision measuring instruments used to measure very small distances, thicknesses, or diameters with high accuracy. These tools are crucial in applications where exact measurements are necessary, such as in mechanical engineering, metalworking, and machining. Micrometers can measure dimensions to the nearest hundredth or even thousandth of a millimeter, making them essential for tasks that require exceptional precision.

Measuring Thickness, Diameter, Length, and Depth

Micrometers primarily function by measuring the thickness, diameter, length, and depth of objects with great precision. The tool typically comprises a calibrated screw mechanism that allows for fine adjustments and precise measurement readings. This capability is particularly useful in settings where components need to fit together within very tight tolerances, ensuring flawless operation and performance.

Types of Micrometers

Like calipers, micrometers come in various types, each designed for specific measurement tasks and accuracy requirements.

Outside Micrometers

Outside micrometers, also known as external micrometers, are used to measure the outside dimensions of an object, such as its diameter or thickness. They have a C-shaped frame that holds an anvil and a spindle, which are adjusted to measure the object between them. This type of micrometer is widely used in metalworking and machining to ensure that parts meet precise dimensional specifications.

Inside Micrometers

Inside micrometers are utilized to measure the internal dimensions of an object, such as the diameter of a hole. They consist of a set of rods or extensions that can be adjusted to the required length. Inside micrometers are vital in quality control processes where the internal measurements of components need to be monitored and verified to meet exact standards.

Three-Point Bore Micrometers

Three-point bore micrometers are specialized tools designed to measure the inside diameter of cylindrical objects, such as pipes or tubes. They feature three contact points that provide a more accurate and stable measurement compared to traditional two-point inside micrometers. Their high precision makes them indispensable in applications where precise internal measurements are crucial.

Key Differences Between Calipers and Micrometers

Accuracy

Resolution Comparison

One of the most significant differences between calipers and micrometers lies in their accuracy. Micrometers generally offer higher resolution and accuracy compared to calipers. For instance, digital micrometers can measure increments as small as 0.001 mm, while digital calipers typically measure with an accuracy of 0.01 mm. This makes micrometers the preferred tool for tasks requiring the utmost precision.

Mechanisms for Measurement

The mechanisms used for measurement also differ between the two tools. Calipers use a sliding mechanism with a main scale and vernier, dial, or digital readout, which facilitate quick and versatile measurements but can be less precise due to potential reading errors. Micrometers, on the other hand, utilize a calibrated screw mechanism that allows for finer adjustments and more precise readings, making them ideal for high-precision tasks.

Measurement Range

Typical Caliper Ranges

Calipers are versatile tools with a broad measurement range. Standard calipers can measure objects ranging from 0 to 150 mm, with larger versions available for extended ranges up to 300 mm or more. This wide range makes calipers suitable for a variety of measurement tasks in different applications, from small components to larger objects.

Typical Micrometer Ranges

Micrometers, however, have a more limited measurement range compared to calipers. Standard micrometers usually measure in ranges from 0 to 25 mm, with specialized micrometers available for larger measurements. Despite their limited range, the higher precision and accuracy of micrometers make them the preferred choice for applications where exact measurements are critical.

Application Range

Versatility of Calipers

Calipers are highly versatile and can be used in a wide range of applications. They are effective for both rough and fine measurements and can measure external and internal dimensions as well as depths. This flexibility makes them an essential tool in many workshops, where they can be used for a variety of tasks from initial measurements to final inspections.

Specialized Use of Micrometers

Micrometers, while less versatile than calipers, excel in specialized applications that require high precision. They are the tool of choice for measuring small and delicate components where even the slightest error can affect the performance and quality of the final product. Industries such as aerospace, automotive, and precision engineering rely heavily on micrometers for quality control and assurance.

Practical Considerations

Cost-Effectiveness

Calipers as a Cost-Effective Solution

Calipers are generally more cost-effective compared to micrometers. Basic analogue calipers are inexpensive, while digital and dial calipers are moderately priced. Their versatility and broad range of applications justify the investment, making them a staple in many workshops. The affordability of calipers is particularly advantageous for small businesses and hobbyists who require reliable measurement tools without the high costs.

Micrometers for Precision

Micrometers, although more expensive than calipers, are worth the investment for tasks that demand the highest precision. The cost is justified by their superior accuracy and specialized design, which ensure reliable and consistent measurements in critical applications. For industries where precision is paramount, such as aerospace manufacturing and quality control in machining processes, the investment in high-quality micrometers pays off in enhanced product quality and reduced errors.

Productivity

Tool Switching and Operation Speed

Another practical consideration is the impact on productivity. Calipers are more versatile and faster to use, making them ideal for quick measurements and tasks that require frequent tool switching. Their ability to measure different dimensions without changing tools can save significant time in a busy workshop environment.

Bulk Measurement vs. Small Tasks

For bulk measurements, calipers are the tool of choice due to their speed and versatility. However, for small and precise tasks, micrometers are more suitable. The higher precision of micrometers makes them indispensable for detailed and exact measurements, even though they may require more time to use compared to calipers.

Selecting the Ideal Tool for Measurements

Choosing the Right Tool for the Application

Selecting the ideal measuring tool depends on the specific needs of the application. For tasks that require a broad measurement range and versatility, calipers are the best choice. They can handle a variety of measurements quickly and efficiently, making them suitable for general use in workshops and manufacturing settings.

Recommendations Based on Usage

For applications demanding high precision and accuracy, micrometers are the preferred tool. They provide reliable and highly precise measurements for critical components, ensuring that all parts meet stringent quality standards. In high-precision industries like aerospace and automotive engineering, micrometers are indispensable tools for quality control and assurance.

Summary of Benefits and Drawbacks

In summary, both calipers and micrometers have their unique benefits and drawbacks. Calipers offer versatility and convenience for a wide range of measurements with moderate accuracy. They are cost-effective and suitable for general measurement tasks. Micrometers, on the other hand, provide unparalleled precision for specialized applications but come with a higher cost and a limited measurement range. Understanding the specific requirements of the measurement task at hand is crucial in selecting the appropriate tool, ensuring accuracy and efficiency in every application.