Factors to Consider When Choosing a Caliper (Cont.)

Measurement Range

The measurement range of a caliper directly impacts its suitability for specific tasks. A caliper with a limited range may not be useful for larger objects, while one with an extensive range might be overkill for small measurements. Calipers typically come with ranges such as 0-150 mm, 0-200 mm, or even 0-300 mm. When selecting a caliper, consider the dimensions of the objects you regularly measure. For intricate, smaller tasks, a caliper with a shorter range offers the necessary precision without the bulk. Conversely, for larger objects, a broader range is essential to ensure comprehensive coverage. However, an overly extensive range can sometimes sacrifice precision, so balance is key.

Material Quality

Material quality is a critical factor for the longevity and reliability of a caliper. High-quality materials, such as stainless steel or carbon fiber, enhance durability and ensure consistent accuracy over time. Stainless steel calipers are highly resistant to corrosion, making them suitable for various environments, including those exposed to moisture. Carbon fiber calipers, on the other hand, are lightweight yet robust, providing ease of handling without compromising strength. Investing in calipers made from superior materials not only ensures long-term use but also guarantees that the tool maintains its precision despite frequent usage or challenging conditions.

Varieties of Calipers

Vernier Calipers

Manual Operation

Vernier calipers are traditional tools that operate manually, requiring the user to align the vernier scale and the main scale to read measurements. This type of caliper demands a certain level of proficiency to interpret the readings accurately. While they might seem challenging for beginners, vernier calipers offer superior precision once mastered.

Examples of Vernier Calipers

High-quality vernier calipers, are renowned for their reliability and accuracy. These brands often provide robust vernier calipers made from durable materials, ensuring precision in demanding environments. Often used in workshops and educational settings, these calipers serve as excellent tools for those requiring exact measurements without the need for digital assistance.

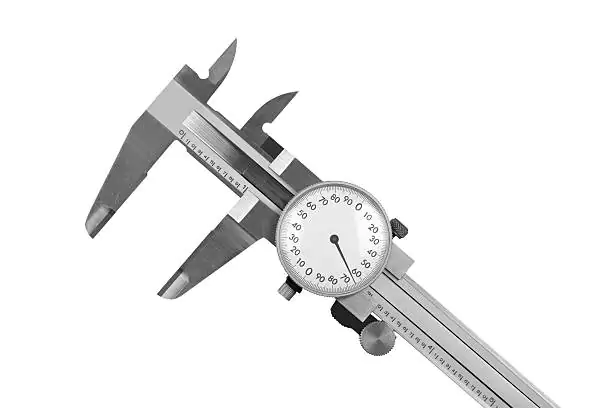

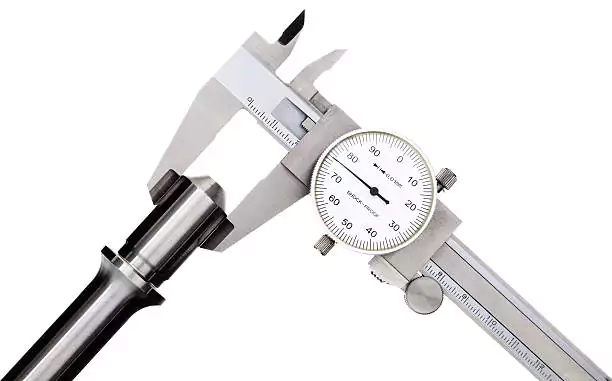

Dial Calipers

Ease of Use

Dial calipers simplify the process of taking measurements by incorporating a circular dial with a needle that points to the measurement reading. This design facilitates quick and easy reading of measurements, making them accessible to users of various skill levels. The dial provides an analog display, which some professionals prefer for its instant readability and lack of dependence on batteries.

Measuring Range

Dial calipers often come in various ranges, with common specifications including 0-150 mm, 0-200 mm, and 0-300 mm. These ranges cover most typical measurement needs, from small components to larger objects. The ease of use combined with varying ranges makes dial calipers versatile tools in both professional and amateur settings.

Examples of Dial Calipers

These calipers are lauded for their precise dial mechanisms and durable construction. Engineers and machinists often rely on these tools for tasks requiring exact measurements, trusting their accuracy and ease of use.

Digital Calipers

High Precision and Ease of Use

Digital calipers are the epitome of modern precision measurement tools. They feature a digital display that provides highly accurate readings effortlessly, often down to the hundred-thousandth of an inch. These calipers are extremely user-friendly, requiring merely a press of a button to take and read measurements. The high precision and straightforward operation make digital calipers an indispensable tool in high-tech fields and precision industries.

Examples of Digital Calipers

Brands like Mitutoyo and iGaging offer top-tier digital calipers that are highly rated for their accuracy and reliability. These models often come with additional features, such as data output ports for transferring measurements to computers or other devices, enhancing their utility in data-driven environments. The precision and advanced features of digital calipers cater to professionals needing accurate and efficient measurement tools.

Comparative Analysis: Vernier, Dial, and Digital Calipers

Resolution and Accuracy

When comparing vernier, dial, and digital calipers, one must consider resolution and accuracy. Digital calipers typically offer the highest resolution, providing readings down to the hundred-thousandth of an inch. Dial calipers, while also precise, generally have a slightly lower resolution, often to the nearest thousandth of an inch. Vernier calipers, though incredibly accurate, require manual interpretation of the scale, which might introduce slight user error. Nonetheless, vernier calipers are capable of high precision with skilled usage.

Ease of Reading

Ease of reading is another crucial factor distinguishing these calipers. Digital calipers stand out due to their electronic displays that present measurements clearly and unambiguously. In contrast, dial calipers provide analog readings through a needle pointing at a scale, which is straightforward but requires more attention. Vernier calipers, however, demand alignment of scales and careful interpretation, making them the most complex to read but highly rewarding in terms of precision for those who master their use.

Cost and Durability

Cost is a significant consideration when choosing a caliper. Vernier calipers are generally the most affordable, as they lack complex mechanisms or electronics. Dial calipers are moderately priced, offering a balance between cost and functionality. Digital calipers tend to be the most expensive due to their advanced features and high precision. However, the durability of these tools often correlates with their construction quality. Vernier and dial calipers, with fewer electronic components, can endure rougher handling and more challenging environments, whereas digital calipers might require careful maintenance to preserve their electronic parts.

Durability Considerations

Durability considerations include the material quality and construction of the caliper. Stainless steel models across all three types provide rust resistance and long-term reliability. However, the absence of electronics in vernier and dial calipers generally makes them more resistant to damage from drops or exposure to harsh conditions. Digital calipers, while precise, need to be handled with more care to protect their digital interfaces and sensors.

Application-Specific Uses for Calipers

Vernier Calipers in Workshops

Vernier calipers are often found in workshops where manual precision is paramount. Their ability to provide detailed measurements without relying on electronic components makes them ideal in environments where rugged, reliable tools are necessary. Skilled craftsmen appreciate the exactness vernier calipers can provide, ensuring that each product or component meets stringent specifications.

Dial Calipers in Professional Settings

Dial calipers are suited to professional settings where a combination of accuracy and ease of use is desired. The analog dial provides quick readings, which is beneficial in fast-paced environments such as automotive workshops or metal fabrication facilities. Their durability and straightforward reading mechanism make them preferred tools for professionals who need reliable measurements without the dependency on electronic displays.

Digital Calipers in Precision Industries

Digital calipers are indispensable in precision industries such as aerospace, biomedical engineering, and high-tech manufacturing. Their high resolution and easy-to-read digital displays make them essential for tasks requiring utmost accuracy and quick conversions between measurement units. The ability to transmit data electronically to software systems also provides a streamlined workflow for documentation and analysis.

Depth Calipers Explained

Definition and Uses

Depth calipers are specialized measuring tools designed to measure depths of slots, grooves, cavities, and blind holes. Unlike traditional calipers, which primarily measure length, width, and diameter, depth calipers focus specifically on the depth dimension. They are equipped with a depth rod or probe that extends to the measured depth, ensuring precise readings even in hard-to-reach or confined spaces.

Measuring Grooves, Cavities, Blind Holes

Depth calipers are crucial in applications such as mold making, machining, and quality control. They accurately measure grooves and cavities’ depths, ensuring that they meet design specifications. Blind holes, often found in mechanical and engineering components, require exact depth measurements to fit other parts properly and function correctly. Depth calipers provide the necessary precision to ensure structural integrity and compatibility.

Examples of Depth Calipers

Examples of reliable depth calipers include the Mitutoyo Depth Micrometer and the Starrett Precision Depth Gauge. These tools are renowned for their precision and ease of use in measuring depths. Their robust construction ensures durability, while their finely engineered depth rods and measurement systems provide accurate and repeatable results.

Accuracy and Reliability

Digital Calipers as the Most Accurate

Digital calipers are widely regarded as the most accurate measuring tools available due to their electronic measurement system. They eliminate the manual reading errors associated with vernier and dial calipers, providing direct digital readouts. This accuracy down to the nearest hundred-thousandth of an inch makes digital calipers indispensable in industries where precision is non-negotiable.

Reasons for High Accuracy

The high accuracy of digital calipers can be attributed to their advanced electronic sensors and microprocessors, which detect and process measurements with minimal deviation. The instant digital display ensures no manual interpretation errors occur, providing clear and exact readings. This technology ensures repeatability and consistency, crucial for maintaining high standards in precision industries.

Dial Calipers and Their Precision

Dial calipers, though slightly less precise than digital calipers, offer significant precision advantages over vernier calipers. The dial mechanism allows for fine adjustments and clear readings, often down to the nearest thousandth of an inch. The combination of a main scale and a dial gauge provides a dual-layer of precision, enhancing measurement reliability when managed by skilled professionals.

Main Scale and Dial Gauge Usage

Using the main scale in conjunction with the dial gauge allows for detailed and exact measurements. The main scale provides basic measurement increments, while the dial gauge fine-tunes the readings to a higher level of precision. This dual approach ensures comprehensive detail, making dial calipers a reliable choice for many professional applications.

Digital vs. Dial Calipers

Advantages of Digital Calipers

Accuracy and Precision

Digital calipers offer unparalleled accuracy and precision, thanks to their electronic measurement systems. The absence of manual interpretation reduces the likelihood of human error, ensuring consistently precise readings. This is particularly beneficial in high-precision industries where even the smallest deviation can lead to significant issues.

Quick Conversions

One significant advantage of digital calipers is the ability to quickly convert between measurement units. With the push of a button, users can switch between inches and millimeters, making these tools highly versatile for various international standards and specifications. This feature saves time and reduces the risk of conversion errors, enhancing efficiency and accuracy.

Advantages of Dial Calipers

Durability and No Battery Requirement

Dial calipers, lacking electronic components, are inherently more durable and can be used in harsher environments without the concern of damaging sensitive electronic parts. Furthermore, they do not require batteries, eliminating the risk of downtime due to power failure. This makes them highly reliable tools for consistent use in various conditions.

Analog Readout Preferences

Some professionals prefer the analog readout of dial calipers, finding the immediate visual feedback and needle movement easy to interpret. The analog system also allows for “seeing” slight variations in measurements, facilitating a more intuitive understanding of the data. This preference is particularly strong among those who have relied on analog tools for extended periods.

Conclusion

Selecting the perfect caliper for precision measurements involves considering numerous factors, including application environment, material quality, measurement range, and specific user needs. Whether opting for vernier calipers for their manual precision, dial calipers for their user-friendly dials and durability, or digital calipers for their high precision and quick unit conversions, understanding the strengths and suitable applications of each type is paramount. By thoroughly evaluating these aspects, professionals and hobbyists alike can choose the right caliper that ensures accuracy, reliability, and efficiency in their work.