Understanding Calipers

Purpose of Calipers

Calipers are essential tools in various fields, notably in engineering, manufacturing, and metalworking. They are designed to measure the distance between two opposite sides of an object, which can be vital in ensuring precise dimensions.

Measuring Inner and Outer Diameters

One of the primary purposes of calipers is to measure both inner and outer diameters. Whether calibrating the diameter of a bore or the thickness of a rod, calipers offer high precision, often to a thousandth of an inch or hundredth of a millimeter. This precision is key in applications such as mechanical engineering, where accurate dimensions can mean the difference between success and failure.

Measuring Length, Width, and Depth

Calipers aren’t limited to diameter measurements. They are also used to measure the length, width, and depth of components. For instance, the depth rod integrated into a caliper can measure the depth of holes or recesses, providing versatile utility in a single tool. This versatility makes calipers indispensable in carpentry, machining, and metalworking.

Importance of Calipers in Precision Measurement

Precision measurement is critical in industries where small deviations can lead to significant issues. For example, in aerospace engineering, the exact dimensions of a component can impact the performance and safety of an aircraft. Calipers provide the accuracy required for such high-stakes measurements. Furthermore, calipers are easy to use and provide quick assessments of dimensions, making them ideal for both initial measurements and quality control processes.

Overview of Caliper Types

Calipers come in various forms, each suited to specific tasks and preferences. The three primary types of calipers are Vernier, Dial, and Digital. Each type has unique advantages and limitations, making them suitable for different applications and user preferences.

Different Types of Calipers

General Characteristics

Understanding the general characteristics of each type of caliper helps in making an informed decision based on measurement needs and conditions.

Measurement Accuracy

All three types of calipers—Vernier, Dial, and Digital—offer high precision, typically up to 0.001 inches or 0.02 millimeters. However, the measurement accuracy can vary slightly based on the tool’s construction and the user’s proficiency.

Calibrated Metric and Inch Scales

Calipers are available for both metric and inch scales, sometimes even offering both on a single instrument. This dual-scale capability makes them versatile for international use, accommodating various standards and ensuring compatibility with global engineering requirements.

Readout Mechanisms

The readout mechanisms distinguish Vernier, Dial, and Digital calipers, each providing unique ways to interpret measurements.

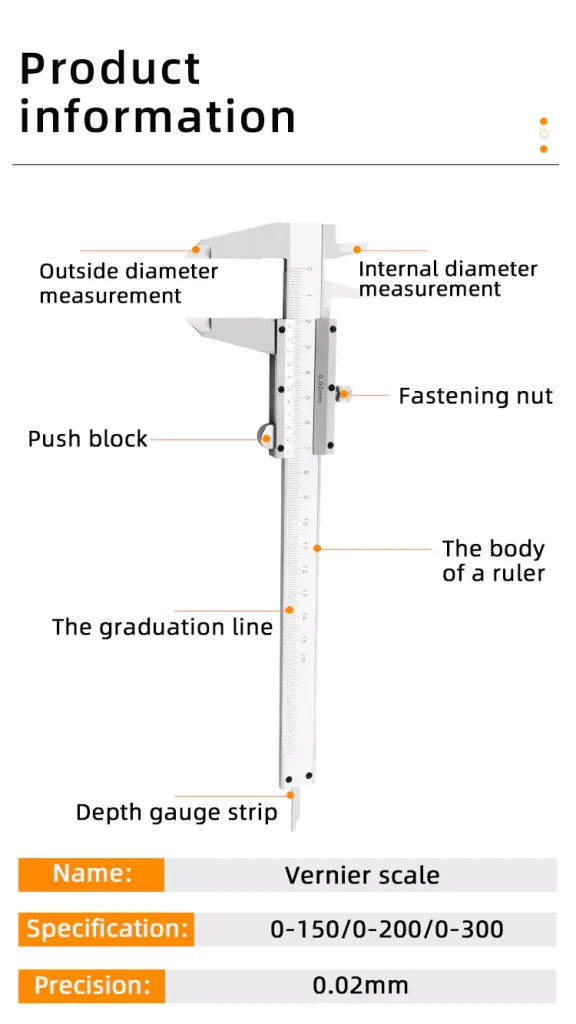

Vernier Scale

Vernier calipers employ a sliding vernier scale to provide precise measurements. This analog system requires the user to interpret the scale themselves, which can be challenging but is highly accurate when used correctly.

Dial Readout

Dial calipers offer an easier-to-read circular dial. The dial readout simplifies measurement interpretation, reducing the likelihood of reading errors. However, its analog nature still requires some skill to use effectively.

Digital Display

Digital calipers use an electronic display to show measurements in a numerical format, making them the easiest to read and use. The displayed measurement can quickly switch between metric and inch units, adding to their ease of use.

Measuring Ranges

Different applications may require different measuring ranges. Standard ranges for calipers are typically 0-6 inches (150 millimeters) and 0-12 inches (300 millimeters), although other sizes are available for specialized tasks.

Standard Ranges (0-6”, 0-12”)

The most commonly used calipers measure ranges from 0-6 inches, suitable for a wide variety of tasks. Larger calipers, with a range of up to 12 inches, are used for measuring wider components and are often found in industrial settings. The choice of range depends on the specific measurement requirements and the size of the objects being measured.

Vernier Calipers

Structure and Function

Vernier calipers are characterized by their analog readout, which involves a main scale and a sliding vernier scale. This structure allows for precise measurements, requiring the user to align the scales to interpret the measurements accurately.

Analog Readout

The analog readout of Vernier calipers involves aligning the zero of the vernier scale with the main scale. This method can take time but ensures high precision when executed correctly. The analog nature also means there are no batteries or electronics involved, which contributes to their reliability.

Interpolation for Improved Readings

One of the key features of Vernier calipers is interpolation. This technique involves estimating the intermediate values between two graduations, allowing for even finer measurements. Skilled users can achieve highly accurate readings through effective interpolation.

Advantages

No Battery Requirement

Vernier calipers do not require batteries, making them reliable in long-term operations without the need for frequent battery replacements. This is particularly beneficial in industrial settings where continuous use is necessary.

Durability and Reliability

Made predominantly from stainless steel, Vernier calipers are built to withstand harsh conditions. They are less susceptible to damage from drops or impacts compared to their digital counterparts, making them more reliable in rugged environments.

Disadvantages

Learning Curve for Accurate Readings

Using Vernier calipers requires practice and skill to interpret the scales accurately. This learning curve can be a disadvantage for new users who may find it challenging to achieve precise readings.

Potential for Reading Errors

Despite their accuracy, Vernier calipers are prone to human error. Misalignment of scales or incorrect interpretation can lead to inaccurate readings, which can be a significant drawback for critical measurements.

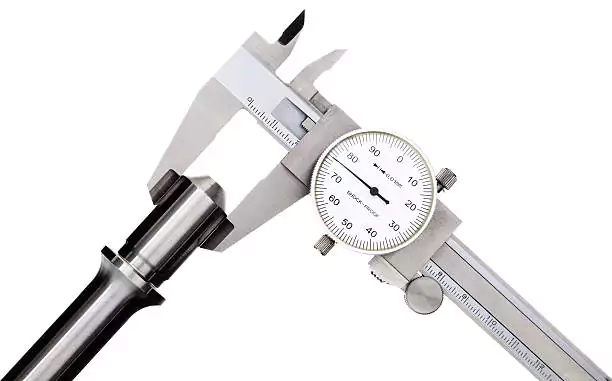

Dial Calipers

Structure and Function

Dial calipers feature a rack and pinion mechanism and a circular dial readout. This combination allows for easy and quick measurements, with the dial giving a direct and readable measurement.

Rack and Pinion Mechanism

The rack and pinion mechanism in dial calipers ensures smooth and precise movement of the sliding jaw. This mechanism translates the linear movement into a rotational dial movement, providing an easy-to-read measurement.

Circular Dial Readout

The circular dial readout presents measurements in a more intuitive manner, reducing the likelihood of errors. The dial typically has a gradient that corresponds to the main scale, helping users to quickly interpret measurements.

Advantages

Ease of Use Compared to Vernier Calipers

Dial calipers are generally easier to use than Vernier calipers. The direct readout from the dial makes them more user-friendly, especially for those who are not experienced with reading scales.

No Battery Requirement

Like Vernier calipers, dial calipers do not need batteries, making them suitable for continuous use without concerns about power availability. This reliability is crucial in professional environments.

Differential Measurements Capability

Dial calipers can be zeroed at any measurement point, allowing for differential measurements. This feature simplifies tasks such as comparing two components or measuring incremental dimensions.

Disadvantages

Sensitivity to Shock and Magnetic Fields

Dial calipers are sensitive to shock and magnetic fields, which can disturb the rack and pinion mechanism or the dial itself. This sensitivity can lead to inaccurate measurements and require recalibration.

Calibration Issues from Misalignment

The analog nature of dial calipers means they can suffer from calibration issues due to misalignment over time. Regular maintenance is necessary to ensure they continue to provide accurate readings.

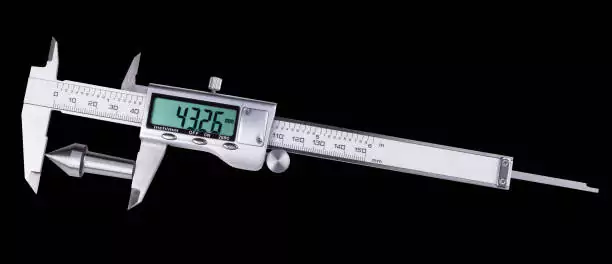

Digital Calipers

Structure and Function

Digital calipers use a linear encoder to measure distance and display it on a digital screen. This setup combines precision mechanics with electronic measurement technology, providing the most straightforward reading experience.

Linear Encoder and Digital Display

A linear encoder inside the digital caliper translates the movement of the sliding jaw into electronic signals. These signals are processed and converted into a digital readout, showing the measurement in an easy-to-read format.

Conversion Between Measurement Units

Digital calipers offer the convenience of switching between metric and inch units with the press of a button. This feature makes them highly versatile, accommodating varying measurement standards without the need for manual conversion.

Advantages

Easy and Fast Readings

Digital calipers provide quick and straightforward readings, reducing the potential for user error. The numeric display eliminates the need for interpreting scales, making them accessible even to novice users.

Zeroing Capability at Any Point

The ability to zero the caliper at any position enhances its functionality, allowing for relative measurements or incremental dimension assessments. This feature is especially useful in tasks requiring precise tolerance checks.

Additional Features (Reading Hold, Data Interface)

Many digital calipers come with additional features such as data hold, which keeps the current reading displayed even after the jaws are moved. Advanced models may also offer a data interface to transfer measurements to a computer, facilitating data analysis and record-keeping.

Disadvantages

Sensitivity to Magnetic Fields, Water, Dirt, and Oil

Digital calipers can be sensitive to environmental conditions such as magnetic fields, moisture, and debris. Exposure to these can affect their accuracy and functionality, making them less reliable in harsh conditions.

Dependence on Battery Power

The reliance on batteries is a notable drawback of digital calipers. Battery failure can hinder the use of the caliper, necessitating the need for spare batteries and regular battery checks, which can be inconvenient in continuous operations.

Key Differences Between Dial, Digital, and Vernier Calipers

Readings

Vernier Calipers: Manual Interpretation

Vernier calipers require manual interpretation of the scale, necessitating practice and accuracy from the user. While precise, this method is susceptible to human error.

Dial Calipers: Instant Dial Readout

Dial calipers offer an instant readout through a circular dial, providing a more straightforward interpretation compared to Vernier calipers. The dial system is more user-friendly, reducing the learning curve.

Digital Calipers: Numeric Display

Digital calipers display measurements in a clear numeric format, offering the simplest and quickest reading method. This feature significantly reduces the possibility of reading errors and makes them the most accessible tool.

Ease of Use

Vernier Calipers: Requires Practice

Vernier calipers demand a higher level of skill to use effectively. The need to interpret the sliding scale accurately can be challenging, especially for beginners.

Dial Calipers: User-Friendly

Dial calipers strike a balance between simplicity and precision. Their ease of use makes them suitable for a broader range of users, including those with less experience in precision measurement.

Digital Calipers: Simplest and Quickest

Digital calipers are the simplest and quickest to use, requiring minimal interpretation or expertise. This ease of use makes them highly suitable for rapid measurements and frequent use in various settings.

Use Conditions

Vernier Calipers: Robust in All Conditions

Vernier calipers are robust and less affected by environmental conditions such as moisture, magnetic fields, or dirt. Their simplicity and durability make them reliable in harsh working environments.

Dial Calipers: Moderate Sensitivity

Dial calipers have moderate sensitivity to environmental factors. While they are generally reliable, care must be taken to avoid shocks and strong magnetic fields that can affect their accuracy.

Digital Calipers: Most Sensitive

Digital calipers are the most sensitive to environmental conditions. Their electronic components can be disrupted by moisture, dirt, and magnetic fields, requiring careful handling and use in controlled environments.

Price

Vernier Calipers: Generally Most Affordable

Vernier calipers are typically the most affordable option. Their simplicity and lack of electronic components contribute to a lower price point, making them an economical choice for precision measurement.

Dial Calipers: Mid-Range Pricing

Dial calipers are priced in the mid-range, offering a balance of affordability and user-friendly features. Their cost reflects the added convenience of the dial readout system.

Digital Calipers: Generally Most Expensive

Digital calipers are generally the most expensive due to their advanced technology and additional features. Their high cost is justified by the ease of use, quick readings, and versatility they offer.

Pros of Each Type

Vernier Calipers

Fewer Moving Parts

Vernier calipers are known for their simple yet effective design. With fewer moving parts than their dial and digital counterparts, they offer increased durability and a reduced likelihood of mechanical failure. This simplicity ensures that Vernier calipers are long-lasting tools suitable for environments where reliability is paramount.

High Reliability and Durability

Due to their robust construction and mechanical design, Vernier calipers are highly reliable. They are less susceptible to damage from shocks or impacts, making them ideal for use in rugged industrial settings. Their durability means that they can withstand heavy usage without degradation of performance.

No Battery Requirement

One of the significant advantages of Vernier calipers is that they do not require batteries. This independence from electronic components not only enhances their durability but also means they are always ready for use. There is no risk of downtime due to battery failure, which is an important consideration in time-sensitive projects.

Dial Calipers

Ease of Reading

Dial calipers are praised for their ease of reading. The dial indicator provides a clear visual representation of measurements, which can be easier to interpret than the scale on a Vernier caliper. This feature is particularly beneficial in situations requiring quick and frequent measurements.

No Battery Requirement

Like Vernier calipers, dial calipers also do not depend on batteries. This similarity means they combine the readability of a dial with the reliability of a purely mechanical device, eliminating concerns related to battery life and ensuring consistent performance.

Easy Zeroing

Dial calipers allow for rapid and straightforward zeroing. This capability is crucial when taking multiple measurements in quick succession, as it ensures accuracy without the need for complex recalibration. Users can reset the dial to zero quickly, enhancing efficiency in measurement tasks.

Digital Calipers

Instant and Clear Readings

Digital calipers offer the convenience of instant and clear digital readouts. This feature eliminates the potential for human error in reading scales, leading to more accurate measurements. The digital display is easy to read, even in low-light conditions, making these calipers highly user-friendly.

Measurement Conversion

One of the standout features of digital calipers is their ability to convert measurements between different units. With just the push of a button, users can switch between metric and imperial units, simplifying the process and saving time. This functionality is particularly useful in international projects where different units of measurement may be required.

Data Recording and Interface Capabilities

Digital calipers often come with advanced features such as data recording and interface capabilities. These tools can connect to computers and other devices to log measurements, facilitating easy data analysis and sharing. This technological advantage makes digital calipers ideal for complex, data-driven projects where detailed measurement logs are necessary.

Cons of Each Type

Vernier Calipers

Requires Practice for Accurate Use

While Vernier calipers are highly reliable, they do require a degree of practice to use accurately. The user needs to learn how to read the scale properly and position the jaws correctly. Without sufficient practice, it can be easy to make mistakes, leading to measurement errors.

Potential for Reading Errors

The precision of Vernier calipers depends heavily on the user’s ability to read the gradations accurately. This manual reading process can lead to errors, especially for inexperienced users or in poor lighting conditions. Such potential for human error necessitates careful training and attention to detail.

Dial Calipers

Sensitivity to Shocks and Misalignment

Although dial calipers offer an easier reading experience, they are more sensitive to physical shocks and misalignment compared to Vernier calipers. The delicate mechanics of the dial can be affected by drops or bumps, leading to inaccurate measurements or even damage requiring professional repair.

Moderate Sensitivity to Magnetic Fields

Dial calipers can also be moderately sensitive to magnetic fields, which can distort the readings. This factor can be an issue in industrial environments where strong magnetic fields are present, potentially affecting the accuracy and reliability of the caliper.

Digital Calipers

Sensitivity to Environmental Factors

Digital calipers are the most technologically advanced but also the most sensitive to environmental factors. They can suffer from issues related to dust, moisture, and temperature extremes, which can affect their electronic components and lead to unreliable measurements if not properly maintained.

Dependence on Battery Power

One of the significant downsides of digital calipers is their dependence on battery power. This reliance means that batteries must be regularly replaced or recharged, adding a layer of maintenance. Moreover, a dead battery can halt work until it is replaced, which could lead to downtime in critical projects.

Applications and Recommendations

Industrial Applications

Machine Shops

In machine shops, precision is paramount. Digital calipers’ ability to provide instant, clear readings and data logging can significantly enhance efficiency and accuracy. Machine shops benefit from the ease of switching between measurement units, facilitating work with different specifications.

Metalworking and Machining

For metalworking and machining operations, Vernier calipers’ robustness and reliability are highly valued. The absence of a battery requirement means they are always operational, a crucial factor in continuous production environments where any downtime can be costly.

DIY and Hobbyist Use

Recommended Types for Beginners

For beginners engaged in DIY and hobbyist activities, dial calipers offer a good balance between ease of use and accuracy. The clear, readable dial simplifies the process of taking measurements, and the lack of a need for batteries ensures consistent availability.

Versatility and Ease of Use

Digital calipers also provide an excellent option for hobbyists who may benefit from the clear digital readout and the ability to easily switch between measurement units. Their user-friendly interface can make them more accessible for those less experienced with precision tools.

Professional Use

Importance of Accuracy and Reliability

In professional settings, the importance of accuracy and reliability cannot be overstated. Professionals often prefer to have multiple types of calipers available to suit different tasks. Vernier calipers might be chosen for their ruggedness, dial calipers for their ease of readout, and digital calipers for their advanced features.

Preference for Multiple Caliper Types

Professionals understand that no single type of caliper is superior in all situations. Therefore, maintaining a variety of calipers ensures that they have the best tool for each specific measurement task, from detailed quality control checks to rough initial measurements.

Summary

No Single Type of Caliper is Superior in All Cases

Each type of caliper has its unique strengths and weaknesses. Vernier calipers offer high durability and no battery dependency but require skill to use correctly. Dial calipers provide an easier reading experience and quick zeroing but are more delicate. Digital calipers deliver instant, clear readings and advanced features but depend on batteries and are more susceptible to environmental conditions.

Importance of Matching Caliper Type to Application

Selecting the right caliper depends on the specific requirements of the task at hand. For high precision and rugged use, Vernier calipers might be best. In situations where quick and easy readability is needed, dial calipers could be more suitable. For advanced data handling and flexibility, digital calipers are the preferred choice.

Final Recommendations for Different Users

- Industrial Users: A combination of Vernier and digital calipers ensures robustness and advanced capabilities.

- DIY Enthusiasts: Dial calipers are a great starting point for their ease of use and readability.

- Professionals: Utilizing all three types ensures that the most appropriate tool is always available for any given measurement task.