Common Points

Non-Destructive Testing

The principal function both a Coating Thickness Gauge and an Ultrasonic Thickness Gauge share is their non-destructive approach to testing. This means that these devices can evaluate the thickness of materials without causing any damage or alteration. Non-destructive testing is critical in various industries such as manufacturing, aerospace, and automotive, where maintaining the integrity of materials is crucial. By possessing this feature, users can ensure continuous quality control and compliance with standards without compromising the inspected parts.

Measurement without Material Destruction

Non-destructive testing provides the benefit of extending the lifespan of the materials being measured. For instance, coatings on pipelines, aircraft, and structures can be assessed periodically for consistency without the need to break or alter them. This advantage leads to significant cost savings in maintenance and repairs. Furthermore, the ability to conduct regular, non-invasive inspections is instrumental in preventing failures and ensuring safety.

Measurement Method

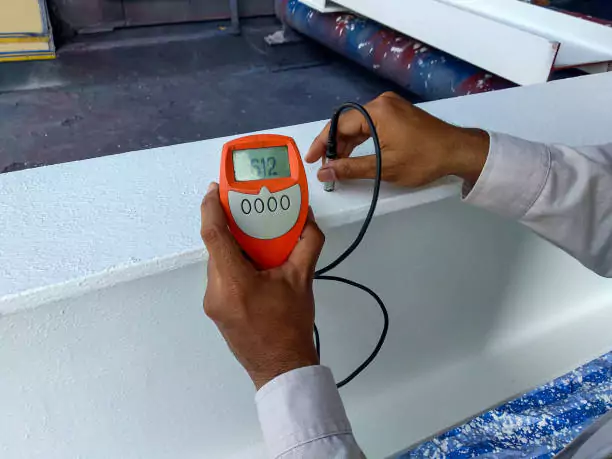

Both types of thickness gauges utilize a contact measurement method that involves the use of probes. The probe is placed on the surface of the material, and it conveys the data needed for the measurement process. This contact approach ensures that measurements are accurate and closely related to the actual surface being examined. The direct contact enhances reliability, making these gauges suitable for critical applications where precision is vital.

Contact Measurement with Probe

Probes used in these thickness gauges are designed to be sturdy and sensitive. They can adapt to various surface contours and compositions to provide accurate readings. Advances in probe technology have further enhanced the ability to measure small areas and complex geometries effectively. High-quality probes minimize user error and improve the repeatability of measurements, reinforcing the dependability of these tools in demanding industrial settings.

Coating Thickness Gauge

Definition and Usage

A Coating Thickness Gauge is specifically designed to measure the thickness of surface coatings. These coatings can range from paint and varnish to non-metallic layers on metallic substrates. The primary usage of this device is to ensure the uniformity and adequacy of coatings which is critical in processes involving protection against corrosion, wear, and other environmental factors.

Focus on Surface Coatings

Surface coatings serve diverse purposes, including aesthetic enhancement, functional improvement, and protection. The ability to monitor the thickness accurately ensures that the coatings fulfill their intended function. For instance, in the automotive industry, precise coating thickness is crucial for both the vehicle’s appearance and its resistance to corrosion and environmental damage.

Accuracy and Resolution

Accuracy and resolution are crucial parameters in evaluating the performance of a Coating Thickness Gauge. Most gauges offer precision down to micrometers, providing highly detailed assessments. The advanced technology embedded in these tools allows for consistent and reliable measurement results.

Measurement Precision (in micrometers)

With precision in the micrometer range, these gauges can detect even the slightest deviations in coating thickness. This level of sensitivity is essential in quality control processes where exceeding or not meeting the specific coating thickness can lead to product failure. High-resolution measurements enhance the ability to perform thorough inspections, ensuring that every layer applied adheres to strict guidelines and requirements.

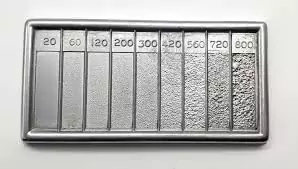

Types of Coating Thickness Gauges

Magnetic Method

The magnetic method is utilized predominantly for measuring non-magnetic coatings on magnetic substrates. This includes applications where paint is applied to steel surfaces. The magnetic properties of the substrate influence the gauge reading, allowing for a precise determination of the coating thickness.

Applications and Materials Measured

Magnetic method gauges are often used in industries such as automotive, shipbuilding, and construction. They are ideal for measuring paint, enamel, and other coating types on ferrous metals. This method’s reliability makes it indispensable in environments where maintaining strict quality and safety standards is paramount.

Eddy Current Method

Another method employed is the eddy current method, suitable for non-conductive coatings on conductive, non-ferrous metal substrates. This technique measures the thickness of coatings like paint on aluminum and other non-magnetic metals.

Applications and Materials Measured

Eddy current thickness gauges are widely used in the aerospace and electronics industries where aluminum and other non-ferrous metals are common. These gauges facilitate the quality control of coatings that serve both protective and functional purposes such as ensuring non-conductivity and preventing corrosion.

Ultrasonic Thickness Gauge

Definition and Usage

An Ultrasonic Thickness Gauge is designed to measure the thickness of base materials rather than surface coatings. This device uses ultrasonic pulse propagation principles to determine the material’s thickness and is thus particularly useful for assessing the integrity of structural components.

Focus on Base Material Thickness

By focusing on the thickness of the base material, ultrasonic gauges help in detecting thinning due to corrosion, wear, and other forms of degradation. This capability is essential in industries where material integrity is crucial, such as oil and gas, shipbuilding, and civil engineering.

Accuracy and Resolution

Ultrasonic Thickness Gauges typically offer measurement precision in millimeters, providing a clear and concise assessment of material thickness. These devices can detect variations that may indicate weaknesses or potential failure points in the material structure.

Measurement Precision (in millimeters)

The resolution in millimeters allows for a thorough evaluation of thicker materials, which is vital for structural applications. Such precision is necessary to ensure compliance with safety standards and to perform predictive maintenance, thereby preventing catastrophic failures.

Principle of Operation

Ultrasonic Thickness Gauges work by emitting an ultrasonic pulse through the material. The pulse propagates through the material and reflects back after reaching the opposite surface. By measuring the time it takes for the pulse to travel through the material and return, the gauge can calculate the thickness with high accuracy.

Ultrasonic Pulse Propagation

The propagation of ultrasonic pulses ensures that measurements can be taken from one side of the material, enabling inspections in situations where accessing both sides is impossible. This non-invasive method ensures operational efficiency and minimal disruption to regular activities.

Material Suitability

Different materials respond differently to ultrasonic waves. Therefore, ultrasonic thickness gauges are calibrated to accommodate a wide range of material types including metals, plastics, ceramics, and composites.

Types of Materials Measured

Ultrasonic thickness gauges can measure a variety of materials, ranging from metals and alloys to plastics and composites. This versatility makes them suitable for diverse applications spanning multiple industries, including manufacturing, construction, and aviation. The ability to precisely measure various materials ensures that these gauges meet the comprehensive needs of today’s industries, providing thorough assessments and maintaining material integrity.