Introduction to Gage Blocks

Definition and Purpose

NIST Definition

Gage blocks, also known as gauge blocks or precision gage blocks, are a fundamental instrument used in precision measurement and calibration. According to the National Institute of Standards and Technology (NIST), a gage block is a precision-ground and lapped length standard that maintains constant length over time. These tools are essential in quality control processes across various industries, ensuring equipment accuracy and performance.

Uses in Calibration and Measurement

Gage blocks play an integral role in the calibration of measuring devices, such as micrometers and calipers. By providing a known standard of length, these blocks allow for accurate setting and testing of metrology equipment. This precision enhances the reliability and consistency of measurements in manufacturing, aerospace, and scientific research fields, among others.

Measurement Systems

Metric System

In the metric system, gage blocks are measured in millimeters, providing a high degree of accuracy and ease of use in international settings. This system is commonly used in scientific and engineering applications where precision and universal standardization are critical.

Imperial System

The imperial system uses inches for measurement, which is prevalent in the United States and certain other regions. Gage blocks in the imperial system are equally precise, allowing for detailed measurements that meet industry standards. Both metric and imperial gage blocks ensure the flexibility and integration of global measurement practices.

Historical Context

Invention by Carl Edvard Johansson

Carl Edvard Johansson, a Swedish inventor, is credited with developing the concept of gage blocks in the early 20th century. His invention provided a reliable means of achieving precise measurements, revolutionizing the manufacturing and engineering industries. This innovation laid the groundwork for modern metrology.

Development of Hoke Design

William Hoke further refined the gage block concept by introducing what is now known as the Hoke design. This development improved the usability and accuracy of gage blocks, making them a staple in precision measurement. Johansson and Hoke’s contributions remain foundational to current precision measurement practices.

Properties of Gage Blocks

Standard Reference Conditions

Temperature

Gage blocks are calibrated under specific temperature conditions, usually 20°C (68°F), to ensure precision. Temperature fluctuations can lead to expansion or contraction of the blocks, affecting measurement accuracy. Maintaining a stable temperature environment is crucial for reliable results.

Barometric Pressure

Barometric pressure can also influence gage block measurements, though its effect is less significant than temperature. Accurate calibration considers the standard atmospheric pressure to minimize discrepancies caused by variations in environmental conditions.

Water Vapor Pressure

The presence of water vapor in the air can lead to corrosion and changes in gage block dimensions. Standard calibration practices account for water vapor pressure to maintain the integrity of the blocks over time.

CO2 Content of Air

The carbon dioxide content in the air can alter the refractive index, impacting the optical measurement of gage blocks. By controlling CO2 levels in the calibration environment, the precision and reliability of measurements can be preserved.

Effect of Atmospheric Conditions

Temperature’s Measurable Effect

Temperature variations can cause significant changes in gage block dimensions, leading to deviations in measurement accuracy. Regular calibration and maintaining a controlled environment ensure that gage blocks remain reliable standards.

Light Wavelength Dependence

The wavelength of light used in optical measurement systems can affect the precision of gage blocks. Calibration processes must consider the specific wavelengths employed to ensure accuracy, particularly in high-precision applications.

Common Shapes of Gage Blocks

Rectangular (Johansson) Design

Description and Uses

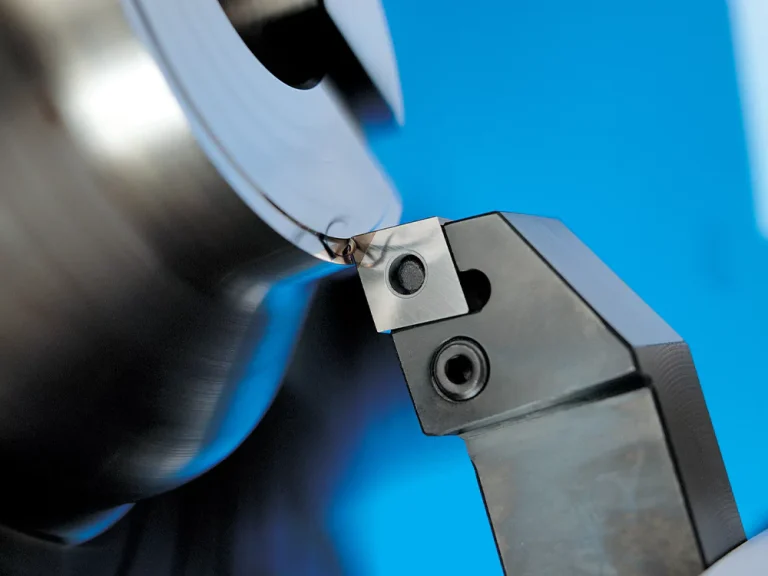

The rectangular design, also known as the Johansson design, is one of the most prevalent shapes in gage blocks. These blocks are characterized by their highly precise, flat, and rectangular surfaces. Rectangular gage blocks are commonly used in calibration labs and manufacturing industries, providing versatility and robustness in various applications.

Square (Hoke) Design

Description and Uses

The square design, known as the Hoke design, features gage blocks shaped in a perfect square for specific calibration tasks. These blocks are particularly useful in applications requiring exact 90-degree measurements. The square gage blocks offer superior stability and ease of wringing in complex measurement setups.

Invention by William Hoke

William Hoke’s invention of the square gage block design addressed specific metrology needs, enhancing the precision and efficiency of measurement processes. His contributions remain significant in modern metrology, with square blocks widely adopted in various precision measurement applications.

Wringing of Gage Blocks

Definition and Process

Wringing is the process of joining two gage blocks by their ultra-flat surfaces to make a precise length standard. This adherence happens through molecular attraction and a thin layer of air between the blocks, creating a bond without the need for external adhesives. The key to successful wringing is ensuring that both surfaces are exceptionally clean and smooth. Proper wringing ensures that the combined length of multiple blocks is accurate to within a few millionths of an inch, thereby providing highly reliable measurement standards.

Maintenance During Wringing

Use of Oil

During the wringing process, a thin layer of oil is sometimes applied to the surfaces of gage blocks to enhance adhesion and protect against wear. This oil layer helps maintain the integrity of the blocks and ensures a more effective bond between the surfaces. However, it is crucial to use the appropriate type of oil to avoid contamination and ensure optimal results.

Risks of Prolonged Wringing

Prolonged wringing can lead to issues such as permanent bonding or corrosion due to environmental factors like humidity. It is essential to periodically separate the blocks and inspect them for any signs of wear or damage. Proper maintenance during the wringing process can extend the lifespan of gage blocks and ensure consistent measurement accuracy.

Available Sizes and Measurement Units

Size Ranges

Common Set Sizes (up to 4 inches)

Gage blocks come in various sizes to accommodate different measurement needs. Common set sizes typically range up to 4 inches or 100 millimeters. These sets are widely used in precision engineering and manufacturing, offering a practical range of lengths for most calibration tasks.

Larger Set Sizes (up to 20 inches)

For more specialized applications, larger gage block sets are available, reaching up to 20 inches or 500 millimeters. These larger blocks are often used in industries requiring extensive calibration ranges, such as aerospace and heavy machinery manufacturing. The availability of larger sizes ensures that gage blocks can meet diverse and demanding measurement requirements.

Custom Orders

Special Orders for Blocks Exceeding 20 inches

In some cases, standard gage block sizes may not suffice for specific applications. Manufacturers offer custom orders for blocks exceeding 20 inches or 500 millimeters to meet unique measurement needs. These special orders are tailored to precise specifications, ensuring that the gage blocks provide the necessary accuracy for specialized tasks.

Gage Block Composition

Materials Used

Steel

Steel is one of the most common materials used in the manufacture of gage blocks. Steel gage blocks are known for their durability, wear resistance, and affordability. They are widely used in various industries due to their robustness and long service life.

Ceramic

Ceramic gage blocks, on the other hand, offer advantages such as rust resistance and the ability to maintain high precision without the need for protective gloves. Ceramic blocks are less prone to thermal expansion and have superior stability in various environmental conditions, making them ideal for certain high-precision applications.

Advantages and Disadvantages

Steel: Commonality and Cost

Steel gage blocks are highly affordable and readily available, making them a popular choice for many users. However, they are susceptible to rust and require careful handling and maintenance to prevent corrosion. The protective oil used during storage and handling can also be a minor inconvenience.

Ceramic: Rust Resistance and No Gloves Required

Ceramic gage blocks offer significant advantages in terms of rust resistance and stability. They do not require the use of protective gloves, simplifying their handling. However, ceramic blocks tend to be more brittle than steel and can be more expensive, which may limit their use in some applications.

Gage Block Tolerance Grades

Overview of Tolerance Grades

Grades K, 00, 0, AS1, AS2

Gage blocks are categorized into various tolerance grades, including K, 00, 0, AS1, and AS2. These grades indicate the level of precision and permissible deviation in the block’s length. Grade K represents the highest precision, often used in laboratory settings, while grades 00, 0, AS1, and AS2 offer varying degrees of accuracy suited for different applications.

Application and Accuracy

Calibration Lab Settings

In calibration lab settings, gage blocks must adhere to the highest tolerance grades to ensure the utmost precision. Grade K and 00 blocks are commonly used in these environments to maintain the strictest accuracy standards. These high-grade blocks minimize measurement errors and ensure reliable calibration of sensitive instruments.

ASME Standards and Limit Deviation

Gage blocks must comply with ASME standards, which specify the allowable limits of deviation for each tolerance grade. These standards ensure that gage blocks provide consistent accuracy across various applications. Understanding the permissible limits of deviation helps users select the appropriate grade for their specific measurement needs.

Example of Accuracy

Grade Zero Blocks

Grade zero gage blocks represent high precision, with deviations typically within a few millionths of an inch. These blocks are suitable for most industrial and laboratory applications, offering a balance of accuracy and cost-efficiency. The reliability of grade zero blocks makes them a preferred choice for many users seeking consistent measurement accuracy.

Gage Block Maintenance

Cleaning Procedures

Removing Debris and Oil

Regular cleaning of gage blocks is essential to maintain their precision. Removing debris and oil from the surfaces ensures that the blocks can be wrung effectively and measure accurately. Using a lint-free cloth and gentle solvents can help remove contaminants without damaging the blocks.

Immersing in Organic Solvents

For thorough cleaning, gage blocks can be immersed in organic solvents that dissolve oils and other residues. This process helps maintain the blocks’ surfaces in pristine condition, ensuring reliable measurements. However, it is crucial to use appropriate solvents that do not harm the blocks’ material.

Ethyl Alcohol Cleaning

Ethyl alcohol is commonly used for cleaning gage blocks due to its effectiveness and rapid evaporation. By wiping the blocks with ethyl alcohol, users can quickly remove contaminants without leaving residues. This cleaning method is simple and efficient, making it a popular choice for maintaining gage block accuracy.

Handling and Storage

Avoiding Damage

Proper handling of gage blocks is vital to prevent damage and maintain their precision. Avoiding drops, impacts, and excessive force ensures the blocks’ surfaces remain flat and smooth. Using protective gloves can also prevent contamination from oils and moisture on the hands.

Proper Storage Practices

Storing gage blocks in a controlled environment is essential for preserving their accuracy. Using protective cases and desiccants helps prevent exposure to moisture and contaminants. Organizing the blocks in a manner that prevents contact between surfaces can also reduce the risk of damage during storage.

Use of Rust Inhibitors for Steel Blocks

For steel gage blocks, applying rust inhibitors can help prevent corrosion and extend their service life. These inhibitors form a protective layer on the block’s surface, shielding it from moisture and other corrosive elements. Regular application of rust inhibitors is a crucial part of maintaining steel gage blocks’ integrity and accuracy.