Introduction to Carbide Inserts

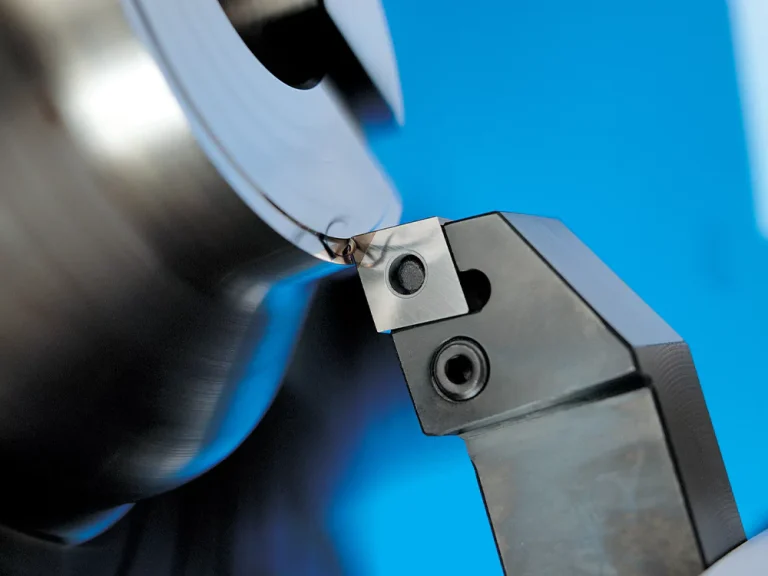

In modern machining, carbide inserts have become indispensable tools, revolutionizing the way we approach metal cutting and shaping. Understanding carbide inserts, their properties, manufacturing processes, and applications is essential for machinists and engineers who seek precision and efficiency in their work.

Definition and Composition

Carbide inserts are cutting tools used extensively in metalworking industries. They are composed primarily of tungsten carbide, which is a compound formed from tungsten and carbon atoms. This composition gives the inserts their hard and wear-resistant properties. Typically, tungsten carbide is bonded with a metallic binder such as cobalt, which enhances the toughness of the material. The resulting inserts can operate at impressive cutting speeds and maintain their integrity under high temperatures.

Production Processes and Precision Processing

The production of carbide inserts involves advanced manufacturing techniques to ensure high precision and consistency. The intricate process begins with selecting high-purity raw materials and follows with a series of controlled steps to create inserts that meet strict specifications. Precision processing, including grinding and finishing operations, is crucial to produce inserts with the exact dimensions and surface finishes required for various applications.

Manufacturing of Carbide Inserts

Starting Materials: Tungsten and Cobalt Powder

The fundamental materials for carbide inserts are tungsten carbide powder and cobalt powder. Tungsten carbide is known for its hardness, while cobalt serves as a binder that lends toughness to the final product. These materials are chosen for their complementary properties, combining to form a composite material capable of withstanding extreme machining conditions.

Mixing and Preparation Process

The mixing and preparation of tungsten and cobalt powders are critical steps in the production of carbide inserts. These processes ensure a uniform distribution of particles and the desired characteristics of the final product.

Mixing with Ethanol and Water

First, the tungsten and cobalt powders are mixed with a liquid medium—typically a mixture of ethanol and water. This step aids in achieving a homogeneous blend, which is essential for consistency in the mechanical properties of the final insert. The slurry is usually milled to achieve the desired particle size and to ensure that the tungsten carbide and cobalt particles are evenly distributed.

Quality Control in Laboratory

Quality control plays an integral role in the production of carbide inserts. Once the mixing process is complete, samples of the slurry are taken to the laboratory for thorough analysis. Various tests are carried out to verify the uniformity of the mixture, particle size distribution, and the chemical composition. Ensuring that these parameters are within specified limits is crucial for the performance and reliability of the carbide inserts in real-world applications.

Pressing and Insert Formation

Following the mixing and preparation, the slurry undergoes a pressing process to form inserts. This process involves placing the mixed material into molds and subjecting it to high pressure to shape the inserts. This is a critical step that determines the initial form and density of the carbide inserts. Precision is required to ensure consistent dimensions and properties across different batches. After pressing, the inserts are subjected to sintering—a high-temperature process that fuses the particles together, resulting in a dense and hard final product.

Properties of Carbide Inserts

High Hot Hardness

One of the most significant properties of carbide inserts is their high hot hardness. Unlike many other materials, carbide inserts maintain their hardness even at elevated temperatures. This trait is particularly beneficial in machining operations where high temperatures are generated due to friction between the cutting tool and the workpiece. High hot hardness allows carbide inserts to perform efficiently without losing their structural integrity.

Excellent Wear Resistance

Wear resistance is another critical property of carbide inserts, making them ideal for industrial applications. This attribute ensures that the inserts can cut through tough materials without degrading rapidly. Carbide inserts can endure prolonged use, making them cost-effective for manufacturers by reducing the frequency of tool changes and downtime.

Comparison with High-Speed Steel

Comparing carbide inserts with high-speed steel (HSS) highlights their superior performance in several areas. While HSS is known for its ability to withstand heavy cutting loads, carbide inserts offer greater hardness and wear resistance. This enables carbide inserts to cut faster and last longer, providing higher efficiency and productivity in machining operations. The superior characteristics of carbide inserts make them a preferred choice in high-precision cutting and high-speed milling applications.

Coatings on Carbide Inserts

Types of Coatings

Coatings play a critical role in enhancing the performance of carbide inserts. Various types of coatings are applied to carbide inserts to increase their lifespan, reduce friction, and improve cutting efficiency.

Titanium Nitride (TiN)

Titanium Nitride (TiN) is one of the most common coatings used on carbide inserts. TiN coating provides a hard, wear-resistant surface that reduces friction and improves the cutting performance of the insert. This coating is particularly beneficial in prolonging tool life and enhancing the aesthetic finish of the workpiece. Additionally, TiN-coated inserts can operate at higher cutting speeds, increasing productivity in machining processes.

Titanium Carbonitride (TiCN)

Titanium Carbonitride (TiCN) coating is another popular choice for carbide inserts. TiCN offers increased hardness compared to TiN and better wear resistance. This coating is well-suited for applications involving high-stress cutting conditions and abrasive materials. The presence of carbon in the coating enhances its durability and toughness, making TiCN-coated inserts ideal for heavy-duty machining tasks.

Titanium Aluminum Nitride (TiAlN)

Titanium Aluminum Nitride (TiAlN) is a high-performance coating known for its excellent thermal stability and oxidation resistance. TiAlN-coated carbide inserts can withstand extremely high temperatures, making them suitable for high-speed cutting applications. This coating forms a protective aluminum oxide layer during machining, which acts as a barrier against heat and wear. TiAlN-coated inserts are widely used in aerospace and automotive industries where precision and reliability are paramount.

Aluminum Titanium Nitride (AlTiN)

Aluminum Titanium Nitride (AlTiN) coating is similar to TiAlN but with a higher aluminum content, providing even better thermal stability and wear resistance. AlTiN-coated carbide inserts are designed for challenging machining operations involving hard and abrasive materials. The enhanced properties of AlTiN make it an excellent choice for applications that require consistent performance under severe conditions, such as milling and drilling hardened steels.

Role in Extending Insert Life

The application of these coatings on carbide inserts significantly extends their life by protecting the cutting edge from wear and thermal damage. Coated inserts can maintain their sharpness for longer periods, reducing the frequency of tool changes and improving overall productivity. By minimizing friction and heat generation, coatings also contribute to better surface finishes on machined parts. In essence, coated carbide inserts offer a combination of durability, efficiency, and cost-effectiveness, making them indispensable tools in modern machining operations.

Uses of Carbide Inserts

Historical Background and Ubiquitous Use

Carbide inserts have a rich history dating back to the early 20th century when they were first developed to address the limitations of traditional cutting tools. Since their introduction, carbide inserts have become ubiquitous in various industries due to their exceptional performance and versatility. They are now integral components in metal cutting, shaping, and finishing operations, transforming manufacturing processes and enabling precision engineering.

Applications in the Metal Cutting Industry

The metal cutting industry greatly benefits from the use of carbide inserts. Their high hardness, wear resistance, and heat tolerance make them suitable for a wide range of applications, including turning, milling, drilling, and threading. Carbide inserts can efficiently machine hard and abrasive materials, providing superior surface finishes and maintaining tight tolerances.

Surgical Tools

In the medical field, carbide inserts are used to manufacture surgical tools and instruments. Their precision and durability are crucial in creating medical devices that require accurate cutting and shaping. Carbide inserts ensure that surgical tools maintain their sharpness and effectiveness, even after repeated use and sterilization.

Jewelry Making

Carbide inserts also find applications in the jewelry industry, where precision and fine detailing are essential. They are used in cutting, engraving, and shaping precious metals and gemstones. The exceptional hardness and wear resistance of carbide inserts allow jewelers to create intricate designs and achieve high-quality finishes on their pieces.

Nuclear Science Industry

The nuclear science industry relies on carbide inserts for machining components used in nuclear reactors and other critical applications. The high-temperature stability and wear resistance of carbide inserts make them suitable for handling materials that are subjected to extreme conditions. Their reliability and precision are vital in ensuring the safety and efficiency of nuclear systems.

Hard Turning and Milling

In the machining industry, carbide inserts are extensively used for hard turning and milling operations. Hard turning involves machining hardened materials with hardness levels exceeding 45 HRC. Carbide inserts can handle these demanding conditions, providing precise cuts and extending tool life. Similarly, in milling operations, carbide inserts offer high material removal rates and superior surface finishes, making them indispensable tools for manufacturers seeking efficiency and precision.

Conclusion to the Article

Importance and Versatility in Various Industries

Carbide inserts hold immense importance and versatility across a wide range of industries. Their unique properties, such as high hardness, wear resistance, and thermal stability, make them ideal for challenging machining operations. Whether in aerospace, automotive, medical, or manufacturing sectors, carbide inserts enable precision, efficiency, and cost-effectiveness. Their ability to maintain performance under extreme conditions underscores their value as essential tools in modern machining.

Future Trends and Developments

Looking ahead, the future of carbide inserts is promising, with ongoing advancements in materials science and coating technologies. Researchers are continuously exploring new compositions and coatings to further enhance the performance and durability of carbide inserts. Developments in nanotechnology and additive manufacturing are expected to bring innovative solutions, enabling even higher precision and efficiency in machining processes. As industries evolve and demand for complex and high-performance components increases, carbide inserts will continue to play a pivotal role in shaping the future of manufacturing.