Understanding High Temperature Ultrasonic Testing

High temperature ultrasonic testing, a specialized variant of ultrasonic testing, plays a vital role in various industries by enabling accurate thickness gaging and flaw detection under elevated temperatures. This advanced technique leverages the principles of sound wave propagation to inspect materials without causing damage, even when subjected to intense heat.

The Basics of Ultrasonic Testing at Elevated Temperatures

Ultrasonic testing involves sending high-frequency sound waves into materials and measuring their reflections to detect imperfections or measure thickness. When applied at high temperatures, this method requires special adaptations to ensure accuracy and equipment safety. Conventional ultrasonic transducers often fail to operate efficiently at these conditions, necessitating the use of specialized high-temperature transducers.

Situations Requiring High Temperature Ultrasonic Testing

Process Industries

In process industries such as petrochemical plants, power generation facilities, and refineries, high temperature ultrasonic testing is indispensable. These industries often operate under extreme thermal conditions, making traditional inspection methods impractical. Thickness gaging in boilers, heat exchangers, and pipelines ensures structural integrity and operational safety, preventing catastrophic failures.

Manufacturing Situations

Manufacturing environments dealing with metal forging, casting, and smelting also benefit immensely from high temperature ultrasonic testing. During these processes, materials reach high temperatures, and continuous quality control is critical. Monitoring the thickness of materials during production helps in maintaining product quality and ensuring conformity to specifications.

Challenges with Conventional Ultrasonic Transducers

Temperature Tolerance Issues

One of the primary challenges with standard ultrasonic transducers is their limited temperature tolerance. Traditional transducers are often engineered for lower temperature ranges, which restricts their application in high-temperature scenarios. Exposure to elevated temperatures can lead to malfunctioning and inaccurate readings, compromising the reliability of the inspection.

Risks of Permanent Damage

Conventional transducers risk permanent damage when subjected to high temperatures. The sensitive piezoelectric elements in these devices are not designed to withstand extreme thermal stress, which can result in degradation or total failure. This limitation underscores the necessity of utilizing high-temperature transducers capable of enduring such harsh conditions.

Specialized Transducers for High Temperature Conditions

Varieties of High Temperature Transducers

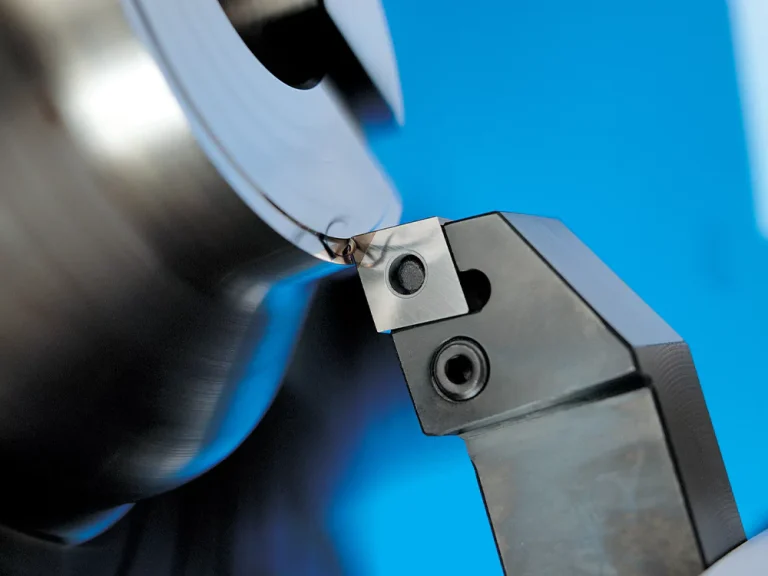

Dual Element Transducers

Dual element transducers are designed specifically for high temperature environments and consist of two piezoelectric elements. These elements function as separate transmitters and receivers, improving near-surface resolution and enhancing flaw detection capabilities. The design also helps in isolating the heat impact, making them more resilient to thermal stress.

Delay Line Transducers

Delay line transducers incorporate a delay line made from materials with high thermal stability. This design helps in delaying the ultrasonic signal, allowing it to cool before reaching the piezoelectric element. Such transducers are highly effective in high-temperature applications where precise thickness measurements are required.

Utilizations of High Temperature Transducers

Thickness Gaging Applications

Corrosion Survey Work

High temperature ultrasonic testing is extensively used in corrosion survey work. In environments such as power plants and chemical processing units, components are susceptible to corrosion at elevated temperatures. Utilizing high-temperature transducers ensures accurate thickness gaging despite thermal stress, aiding in the early detection of corrosion and timely maintenance.

Precision Thickness Gaging

Precision thickness gaging is critical in manufacturing processes where material specifications must be met precisely. High temperature transducers facilitate accurate measurements even during hot rolling, forging, and extrusion processes. This ensures that products meet industry standards and specifications, reducing waste and improving quality control.

By leveraging advancements in high temperature ultrasonic testing, industries can maintain robust quality assurance and operational efficiency despite challenging thermal conditions.

Flaw Detection Applications

Flaw detection is an essential application of high temperature ultrasonic testing in ensuring the integrity and safety of materials under elevated thermal conditions. Identifying imperfections such as cracks, inclusions, or voids can prevent potential failures in critical components. Different types of high temperature transducers play a significant role in flaw detection applications.

Dual Element Transducers in Flaw Detection

Dual element transducers are highly effective in flaw detection due to their improved near-surface resolution. By having separate transmit and receive elements, they can distinguish between signals reflected from flaws and those from the material surface. This enhances the accuracy of detection, especially in thin materials or near-surface defect scenarios, ensuring reliable identification of potential issues.

Delay Line Transducers in Flaw Detection

Delay line transducers, equipped with a thermally stable delay line, help in flaw detection by cooling the signal before it reaches the piezoelectric element. This design makes them suitable for high-temperature environments where precise flaw identification is required. Delay line transducers are particularly useful in detecting flaws in thick sections or materials with varying thermal properties, ensuring comprehensive evaluation under extreme conditions.

Angle Beam Transducers with High Temperature Wedges

Angle beam transducers, when used with high temperature wedges, offer another approach to flaw detection under elevated thermal conditions. These transducers introduce ultrasonic waves at an angle, making them effective in detecting planar flaws such as cracks and delaminations. The high temperature wedges ensure that the transducer can operate effectively without thermal degradation, providing reliable flaw detection even in challenging environments.

Couplants for High Temperature Testing

Couplants play a critical role in ultrasonic testing, facilitating the transmission of ultrasonic waves from the transducer into the test material. At elevated temperatures, standard couplants often fail to perform effectively, necessitating the use of advanced formulations.

Limitations of Standard Couplants

Propylene Glycol, Glycerin, and Ultrasonic Gels

Standard couplants such as propylene glycol, glycerin, and ultrasonic gels have limitations when used in high temperature environments. These materials can degrade quickly under heat, losing their coupling efficiency. As a result, ultrasonic signal transmission might be impaired, leading to inaccuracies in thickness gaging and flaw detection.

Advanced Couplants for High Temperatures

Advanced couplants are formulated to withstand higher temperatures without losing effectiveness. These specialized couplants maintain their viscosity and coupling properties, ensuring reliable ultrasonic testing under thermal stress.

Solutions for Medium Temperatures

For medium temperature ranges, couplants with moderate thermal stability are often sufficient. These couplants can endure temperatures up to 250°C (482°F) without significant degradation, making them suitable for various industrial applications where temperatures are high but not extreme.

Remedies for Higher Temperature Ranges

In environments where temperatures exceed 250°C (482°F), advanced high-temperature couplants are required. These couplants, designed to operate efficiently at temperatures reaching up to 600°C (1112°F), provide reliable performance in the most demanding conditions, ensuring accurate ultrasonic measurements and flaw detections.

Handling and Safety Concerns

Handling and safety concerns are pivotal when dealing with high temperature couplants. Proper handling techniques and safety measures ensure the effective use of these materials without risks.

Vapor Auto-Ignition Risks

One significant safety concern with high temperature couplants is the risk of vapor auto-ignition. At elevated temperatures, some couplants can produce volatile vapors that might ignite spontaneously. It is crucial to use couplants with low volatility and implement proper ventilation measures to mitigate this risk.

Management of Dried Residues

Dried residues left by couplants can interfere with subsequent testing and cause equipment malfunctions. Efficient cleaning procedures and the use of couplants that leave minimal residue are essential to maintain the integrity of testing equipment and ensure consistent results.

Effective Test Techniques at Elevated Temperatures

Successful ultrasonic testing at high temperatures requires specialized techniques to ensure accuracy and equipment longevity. These techniques include managing duty cycles, optimizing coupling methods, and utilizing advanced functions like gain boost.

Duty Cycle Considerations

Optimal Contact Time Recommendations

To avoid damage to the transducer, it is important to limit the contact time with the hot surface. Optimal contact time recommendations suggest short bursts of contact, typically not exceeding several seconds, to minimize thermal stress on the transducer.

Required Cooling Intervals

Intermittent cooling intervals are necessary to allow the transducer to dissipate heat accumulated during testing. These intervals help in maintaining the operational integrity of the device and prolong its lifespan, ensuring reliable performance over extended periods.

Proper Coupling Methods

Efficient coupling methods are critical for effective high temperature ultrasonic testing. Proper application of couplants and residue management play a significant role in maintaining test accuracy.

Applying the Couplant Efficiently

Applying the couplant efficiently involves spreading a thin, uniform layer between the transducer and the test material. This ensures maximum contact and optimal sound transmission, facilitating accurate thickness gaging and flaw detection.

Residue Removal Techniques

Effective residue removal techniques are essential to avoid any interference with the test results. Utilizing appropriate cleaning agents and methods to remove dried couplant residues ensures that the transducer maintains good surface contact and consistent performance.

Utilizing Gain Boost Functions Effectively

Employing Gain Boost Functions for Clarity

Gain boost functions enhance the clarity of ultrasonic signals by amplifying weaker reflections that may occur in high temperature environments. Employing these functions helps in distinguishing between genuine flaw indications and noise, improving the reliability of test results.

Adjusting for Velocity Variations

Impact of Temperature on Sound Velocity

Temperature variations can significantly impact the velocity of sound in different materials. As temperature increases, the sound velocity can change, affecting the accuracy of thickness measurements and flaw detection.

Importance of Recalibration to Maintain Accuracy

Recalibration is crucial to maintain measurement accuracy under varying temperatures. Periodically adjusting the calibration settings to account for changes in sound velocity ensures that the ultrasonic testing results remain reliable and accurate.

Zero Recalibration Necessities

Periodic Re-Zeroing Explanation

Periodic re-zeroing of ultrasonic equipment is necessary to ensure baseline accuracy in measurements. This process involves calibrating the device to a known zero point, compensating for any drift that may have occurred due to prolonged use or thermal effects. Regular re-zeroing maintains the precision of thickness gaging and flaw detection, ensuring consistent and reliable results.

In conclusion, high temperature ultrasonic testing is an invaluable tool in industries where elevated thermal conditions are commonplace. From ensuring the structural integrity of process industry components to maintaining quality in manufacturing, the use of specialized transducers, advanced couplants, and effective testing techniques ensures reliable and accurate ultrasonic inspections. By understanding and implementing these advanced methodologies, industries can achieve enhanced safety, quality, and operational efficiency.