The Fundamentals of Ultrasonic Thickness Gauging

Overview of Ultrasonic Thickness Gauging

Ultrasonic Thickness Gauging is an essential technique utilized across various industries to measure the thickness of materials without causing any damage. By transmitting ultrasonic waves through a material and measuring the time it takes for the echoes to return, this non-destructive testing method offers high precision and reliability. Industries such as aerospace, automotive, manufacturing, and energy production frequently rely on Ultrasonic Thickness Gauging to monitor material integrity, ensure safety standards, and comply with regulatory requirements.

Historical Background

Early Developments in the 1940s

The origins of Ultrasonic Thickness Gauging can be traced back to the 1940s. During World War II, there was a heightened need for accurate measurements of vessel hulls and aircraft components to maintain structural integrity and ensure operational safety. Early ultrasonic techniques were rudimentary, relying on basic pulse-echo methods to gather data on material thickness. These initial advancements set the foundation for further innovation in non-destructive testing technologies.

Advances in the 1970s

The 1970s witnessed significant advancements in Ultrasonic Thickness Gauging with the development of more sophisticated equipment and techniques. Enhanced transducer technology allowed for better resolution and higher accuracy in thickness measurements. The introduction of digital electronics and more advanced signal processing methods facilitated more precise and easier-to-interpret results. This decade also saw the emergence of portable ultrasonic devices, making on-site inspections more feasible and convenient.

Modern Innovations in Microprocessor Technology

Modern Ultrasonic Thickness Gauging has been dramatically transformed by innovations in microprocessor technology. Microprocessors enable real-time data processing, digital signal enhancement, and automated defect recognition. These technological advancements have expanded the capabilities of ultrasonic gauges, allowing for more complex assessments, higher-speed operations, and integration with other testing modalities. Contemporary gauges can store vast amounts of data and provide instant feedback, which enhances both the efficiency and accuracy of thickness measurements.

Measurement Capabilities

Suitable Materials

Metals

Ultrasonic Thickness Gauging is highly effective for measuring the thickness of various metals, including steel, aluminum, and titanium. The high density and homogenous nature of metals ensure reliable ultrasonographic readings, which is critical for applications in construction, manufacturing, and aerospace industries.

Plastics

Plastic materials, both rigid and flexible, can also be accurately measured using ultrasonic techniques. This is particularly useful in the production of plastic components where consistent wall thickness is crucial for performance and quality assurance.

Composites

In the realm of advanced manufacturing, composite materials have gained prominence due to their lightweight and high-strength properties. Ultrasonic Thickness Gauging helps in assessing the uniformity and integrity of composite structures, which is essential in industries such as aerospace and automotive engineering.

Fiberglass

The non-destructive evaluation of fiberglass components, often used in marine and transportation industries, is efficiently conducted using ultrasonic gauging. It helps in detecting delaminations and structural weaknesses that could lead to failures.

Ceramics

Ceramics, commonly used in electronics, medical devices, and protective coatings, can be gauged ultrasonically for precise thickness measurements. This is important for maintaining the desirable electrical, thermal, and mechanical properties of ceramic materials.

Glass

Glass products, especially those used in critical applications like automotive windshields and aerospace windows, require precise thickness measurements that ultrasonic gauging can provide, ensuring durability and safety.

Liquid Levels

Not limited to solids, Ultrasonic Thickness Gauging can also measure liquid levels in containers. By determining the distance from the sensor to the liquid surface, this technique is essential for applications in the chemical and pharmaceutical industries.

Biological Samples

In medical applications, ultrasonic gauging is used to measure the thickness of biological tissues. This non-invasive method supports various diagnostic and research activities, emphasizing the versatility of this technique.

Unsuitable Materials

Wood

Due to its heterogeneous and porous nature, wood is not ideal for ultrasonic gauging. The irregularities within the wood structure scatter ultrasonic waves, leading to unreliable measurements.

Paper

The thin and fibrous composition of paper makes it unsuitable for ultrasonic measurements. The low density and compressibility of paper result in poor acoustic impedance, complicating thickness evaluation.

Concrete

Concrete’s high heterogeneity and the presence of air pockets significantly hinder the effectiveness of ultrasonic waves. This makes it challenging to obtain accurate thickness measurements, although specialized techniques are under development for particular uses.

Foam Products

Foam products, with their high air content and low density, are challenging to measure using ultrasonic techniques. The ultrasound waves get absorbed or scattered, leading to inaccurate results, making other methods preferable for these materials.

Operational Mechanisms of Ultrasonic Thickness Gauges

Basics of Sound Energy

Frequency Spectrum

The frequency spectrum of ultrasonic waves is crucial to understanding how Ultrasonic Thickness Gauging works. Frequencies typically range from 1 MHz to 20 MHz, suitable for penetrating various materials and obtaining clear readings. The choice of frequency depends on the material type and desired measurement resolution.

Ultrasound Definition

Ultrasound refers to sound waves with frequencies above the audible range for humans, which is about 20 kHz. These high-frequency sound waves can propagate through materials, enabling accurate thickness measurements without physical alteration or damage to the object being examined.

Working Principle

Sound Pulse Generation

The operational mechanism starts with the generation of short sound pulses by a transducer. These pulses travel through the material, and some energy is reflected back to the transducer when encountering a boundary.

Echo Detection

The returning echoes are detected by the same or a separate transducer. The time between the emitted pulse and the received echo is precisely measured. This time delay is directly related to the thickness of the material.

Mathematical Relationship (T = V x (t/2))

The thickness (T) of the material is calculated using the formula T = V x (t/2), where V is the sound velocity in the material, and t is the time taken for the echo to return. Accurate knowledge of the material’s sound velocity is essential for precise measurements.

Calibration and Coupling

Importance of Sound Velocity

Calibration is crucial because it ensures that the ultrasonic gauge provides accurate readings. This involves setting the gauge to the known sound velocity of the tested material. Different materials have unique sound velocities, which must be accurately calibrated to ensure correct measurements.

Common Couplants

Couplants, typically gels or liquids, are used between the transducer and the surface to eliminate air gaps, facilitating proper transmission of ultrasonic waves. Common couplants include glycerine, gel, and oils, each selected based on compatibility with the material and environmental conditions.

Different Measurement Modes in Ultrasonic Thickness Gauging

Mode 1: Pulse/Echo

The Pulse/Echo mode is one of the most commonly used methods in Ultrasonic Thickness Gauging. It involves sending a pulse of ultrasound into the material and measuring the time it takes for the echo to return from the back wall. This mode is particularly useful for general-purpose applications where a single boundary reflection suffices. Industries often use this mode to measure the thickness of metal plates, rods, and large structures. Its simplicity and effectiveness in a wide range of materials make it a go-to method for routine inspections.

Mode 2: Echo-Echo

The Echo-Echo mode provides significant advantages in situations involving sharp radii and high-temperature measurements. In this mode, multiple reflections within the material are analyzed to determine thickness. This is particularly beneficial in components with complex geometries where single reflections may not provide accurate readings. Echo-Echo mode is also advantageous in high-temperature environments because it minimizes the effects of surface irregularities and temperature gradients. This makes it suitable for components in engines, turbines, and other high-stress environments.

Mode 3: Multiple Echo

Multiple Echo mode is designed for applications requiring high accuracy and resolution. It uses several echo signals to refine the thickness measurement, making it ideal for thin materials where precision is paramount. This mode is beneficial in industries such as aerospace and electronics, where even slight variations in material thickness can have significant impacts on performance and safety. The ability to obtain high-resolution data ensures that any deviations are promptly detected and addressed, maintaining the integrity and functionality of critical components.

Types of Gauges Utilized in Ultrasonic Thickness Measurement

Corrosion Gauges

Corrosion gauges are specialized ultrasonic devices designed to assess the thickness of metal surfaces and detect corrosion. They are extensively used in industries like oil and gas, shipping, and power generation, where metal pipes and tanks are prone to corrosion. These gauges often feature dual-element transducers, which improve accuracy in measuring corroded surfaces by reducing the effects of surface roughness. By providing reliable data on material degradation, corrosion gauges help in planning maintenance activities and preventing catastrophic failures.

Precision Gauges

Precision gauges are tailored for applications demanding highly accurate thickness measurements, especially in smooth metals and plastics. These gauges typically use single-element transducers, which offer high resolution and precision. Industries such as manufacturing, aerospace, and medical device production rely heavily on precision gauges to ensure that components meet stringent specifications. The detailed measurements provided by these gauges facilitate quality control and product consistency, which are essential for maintaining industry standards and customer satisfaction.

Various Transducer Types for Ultrasonic Thickness Gauging

Contact Transducers

Contact transducers are designed for direct contact applications, where the transducer is placed against the material surface using a couplant. They are widely used for on-site inspections of metal, plastic, and composite structures. These transducers are favored for their simplicity and ease of use, making them suitable for routine maintenance checks in construction, automotive, and aerospace industries. Their ability to provide quick and reliable measurements enhances operational efficiency and safety.

Delay Line Transducers

Delay line transducers are equipped with a delay line that separates the transducer from the material surface. This design is particularly useful for thin material measurements and high-temperature applications. The delay line allows the sound waves to cool down before entering the transducer, preventing damage from high heat. These transducers are essential for industries like electronics and aerospace, where precise measurements of thin materials are critical. They also offer advantages in high-temperature environments, such as engine components, by providing accurate data without compromising the transducer’s integrity.

Immersion Transducers

Immersion transducers are used in applications where the material is immersed in a liquid medium. This setup is beneficial for on-line or in-process measurements, providing continuous data collection without interrupting production. Industries such as automotive, manufacturing, and food processing utilize immersion transducers to monitor material thickness during production processes. The ability to integrate these transducers within automated systems enhances productivity and ensures consistent product quality.

Dual Element Transducers

Dual element transducers consist of two separate elements: one for transmitting and one for receiving ultrasound waves. This configuration is particularly effective for measuring the thickness of corroded surfaces and other challenging materials. Industries that deal with aging infrastructure, such as oil and gas and maritime sectors, often use dual element transducers to assess the condition of metal structures. The separation of transmitting and receiving elements reduces the impact of surface roughness, providing more accurate measurements in challenging environments.

Considerations for Effective Use of Ultrasonic Thickness Gauges

Material Factors

Material properties significantly influence the effectiveness of Ultrasonic Thickness Gauging. Engineering materials, such as metals and plastics, provide reliable readings due to their uniform structure. However, attenuating materials, like rubber or polymers, absorb ultrasound waves, potentially leading to inaccurate measurements. Understanding the specific properties of the material being measured, including its acoustic impedance and density, is crucial for selecting the appropriate gauging technique and transducer type.

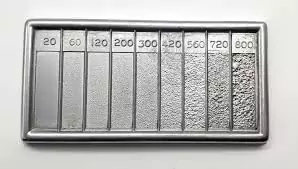

Thickness Range

The choice of ultrasonic frequency is vital for accurate thickness measurements. High frequencies, typically above 10 MHz, are used for thin materials, providing higher resolution and sensitivity. Conversely, low frequencies, around 1-5 MHz, are suitable for thicker materials, allowing deeper penetration of ultrasound waves. Selecting the appropriate frequency ensures that the gauge can detect the relevant echoes, yielding accurate thickness readings. This consideration is crucial for applications ranging from thin plastic films to thick steel plates.

Geometry

The geometry of the material or component being measured can affect the accuracy of ultrasonic thickness gauges. Curved surfaces, grooves, and cavities present challenges due to the potential for sound waves to scatter or reflect unpredictably. Specialized transducers, such as delay line or dual element types, can mitigate these challenges by providing more controlled sound wave transmission. Understanding the shape and features of the component ensures that the chosen technique and transducer will provide accurate readings.

Temperature

Temperature variations can impact the performance of ultrasonic thickness gauges. High temperatures can affect the properties of the transducer and the material, leading to measurement inaccuracies. Contact transducers may have limitations in high-temperature environments, as prolonged exposure to heat can degrade their performance. Delay line and immersion transducers offer solutions by isolating the transducer from direct heat or using a liquid medium to stabilize temperature. Accounting for temperature factors ensures that measurements remain accurate across different operating conditions.

In conclusion, Ultrasonic Thickness Gauging is a sophisticated and versatile technique that serves a wide array of industrial applications. By understanding the fundamental principles, measurement capabilities, operational mechanisms, and various modes and transducers, professionals can effectively utilize this technology to maintain material integrity and ensure safety standards. The continuous advancements in microprocessor technology and equipment design promise even greater capabilities and precision in the future, solidifying the importance of Ultrasonic Thickness Gauging in industry.