Frequently Asked Questions

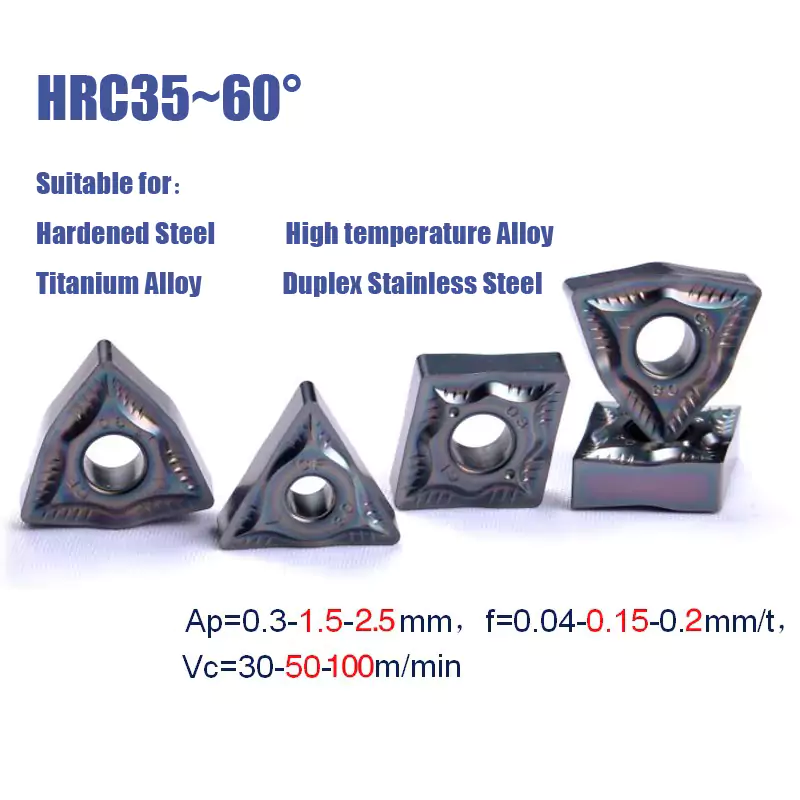

WNMG carbide inserts are engineered to handle a variety of materials, including steel, stainless steel, cast iron, and non-ferrous metals. Their robust construction and specific geometries ensure optimal performance across these different materials, maintaining wear resistance and prolonging tool life.

The website lists several sizes for the WNMG carbide inserts, including WNMG080404 and WNMG080408. These numbers refer to the insert’s dimensions, which are standardized to ensure compatibility with a wide range of tool holders and machining setups.

Yes, WNMG carbide inserts are highly suitable for machining cast iron. Their toughness and wear resistance make them ideal for dealing with the abrasive nature of cast iron. The inserts’ design ensures efficient chip formation and heat dissipation, which is crucial when working with this material.

WNMG carbide inserts offer several advantages:

- Versatility: Suitable for various turning applications, including roughing and finishing.

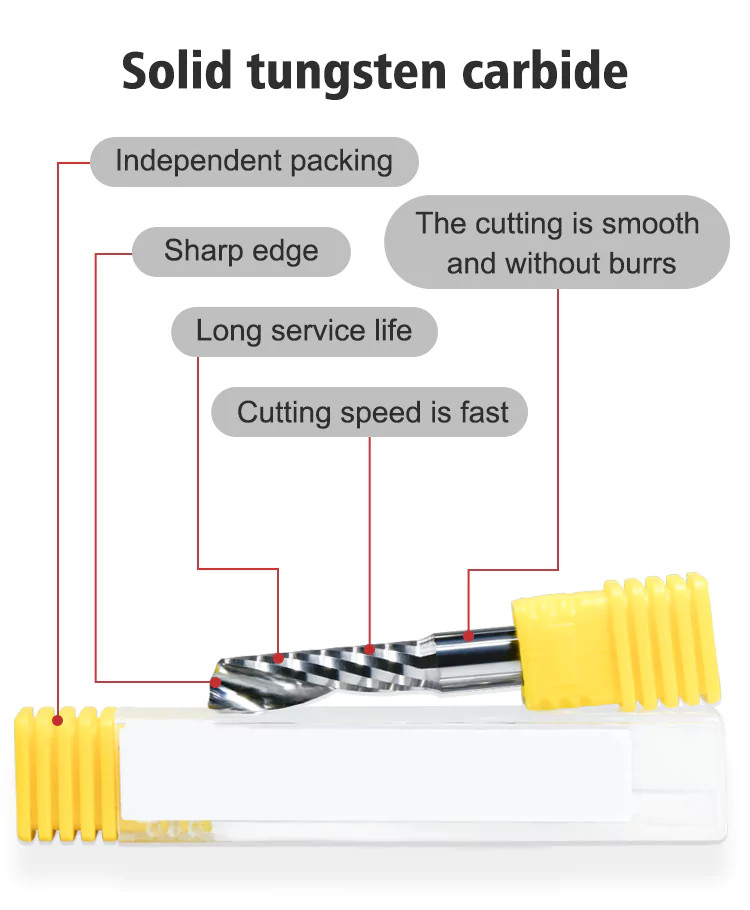

- Durability: Made from tungsten carbide, these inserts exhibit high hardness and wear resistance.

- Cost-Effective: The inserts are indexable, meaning they can be rotated to use multiple cutting edges, thus extending their lifespan and reducing costs.

- Efficiency: The design allows for effective chip control and smooth machining operations, resulting in better surface finishes and higher productivity.

- Compatibility: WNMG inserts can be used with a wide range of materials, including steel, cast iron, and non-ferrous metals.

The WNMG carbide inserts are coated with PVD (Physical Vapor Deposition) technology. This coating process enhances the wear resistance and extends the tool life by providing a hard, wear-resistant surface. The PVD coating is typically applied in a thin layer, which helps maintain the sharpness of the cutting edge while reducing friction and heat generation during the cutting process. This makes PVD-coated inserts particularly suitable for high-speed machining and applications involving difficult-to-machine materials.

The WNMG carbide insert is primarily used for turning and facing operations in CNC lathe machines. Its design, featuring a negative 6° cutting edge angle, makes it suitable for heavy-duty cutting tasks. These inserts are particularly effective in both roughing and finishing operations, providing versatility for a range of machining applications.

To install WNMG carbide inserts on your lathe:

- Preparation: Ensure the machine is turned off and the tool holder is clean.

- Insert Placement: Place the WNMG insert into the tool holder’s insert pocket, aligning it properly.

- Secure the Insert: Tighten the insert using the appropriate clamp or screw, ensuring it is firmly seated without over-tightening to avoid damaging the insert.

- Check Alignment: Verify that the insert is correctly positioned and aligned with the cutting edge at the desired orientation for the specific machining operation.

- Test Run: Perform a test cut at a low speed to ensure the insert is securely installed and functions correctly.

The WNMG inserts are made from tungsten carbide, a composite material composed of tungsten and carbon atoms. Tungsten carbide is known for its high hardness, wear resistance, and ability to withstand high temperatures, making it an ideal material for cutting tools. The inserts may also feature a PVD coating to further enhance their durability and performance. Tungsten carbide’s properties ensure that the WNMG inserts maintain sharpness and effectiveness in various machining applications, including turning, facing, and threading.

The primary difference between WNMG080404 and WNMG080408 inserts lies in their dimensions:

- WNMG080404: This insert typically has a smaller cutting edge length and is suitable for finer, more precise machining operations where a higher degree of accuracy and a smoother surface finish are required.

- WNMG080408: This insert features a larger cutting edge length, making it suitable for heavier cuts and roughing operations where material removal rate is prioritized over surface finish. The larger size also generally means a sturdier insert capable of handling more demanding machining tasks.

Yes, WNMG carbide inserts are highly wear-resistant. They are made from tungsten carbide, a material known for its exceptional hardness and durability. Additionally, the PVD coating enhances their wear resistance by providing a tough, protective layer that reduces friction and heat buildup during machining. This combination ensures that the inserts maintain their cutting performance over extended periods, even under demanding conditions, leading to longer tool life and reduced downtime.

Reviews

There are no reviews yet.