| item | value |

| Customized support | OEM, ODM, OBM |

| Place of Origin | China |

| Brand Name | PROCNCTOOL |

| Model Number | 4NKT060308R |

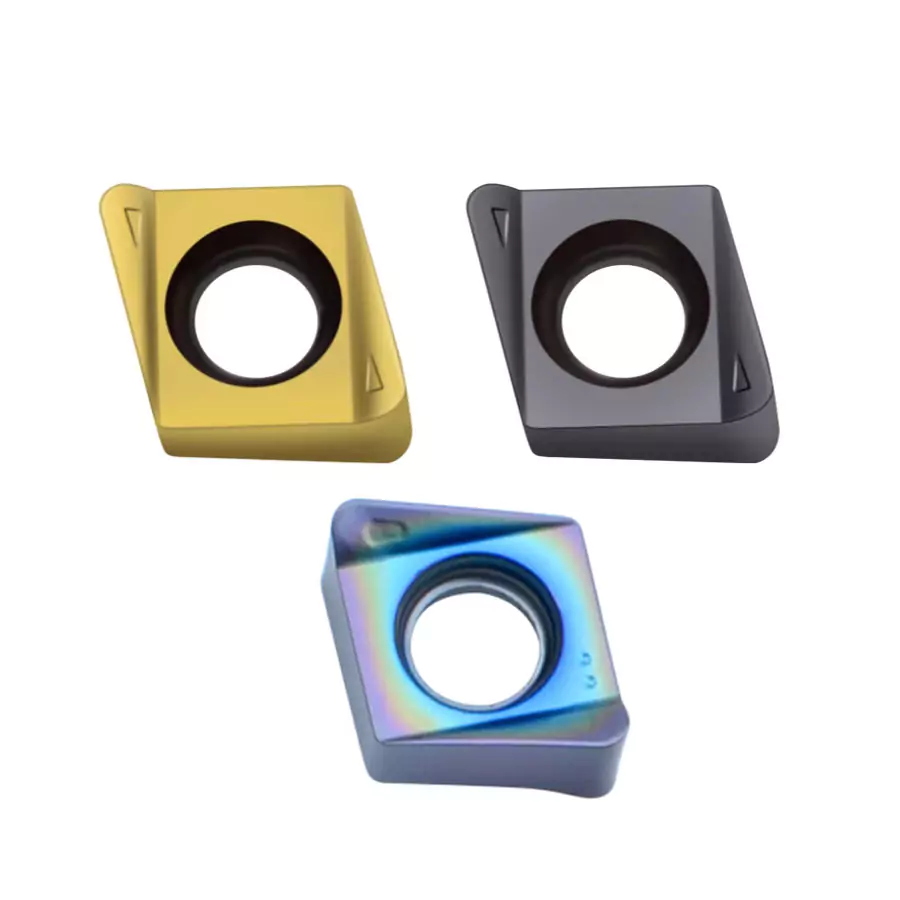

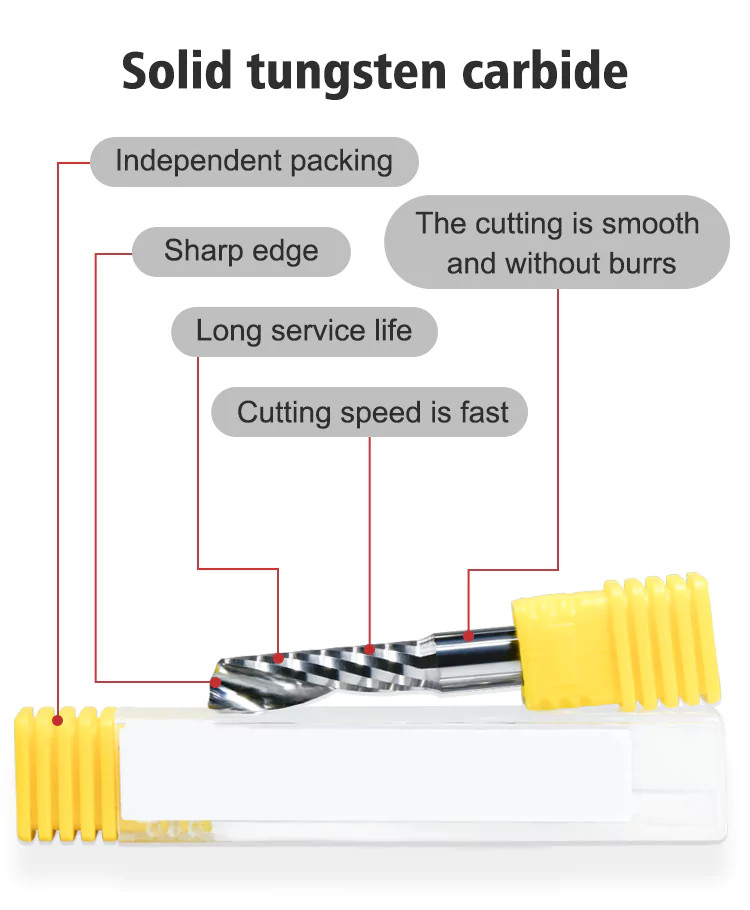

| Material | Tungsten Carbide |

| Coating | AlTiN, TiAIN, TiCN |

| Product Name | Solid Carbide Milling Inserts |

| Suitable for | Steel machining |

| Application | CNC Milling Machining |

| Usage | CNC Machine Center |

| Quality | Durable & free sample for testing |

| Type | Miling Cutter Inserts |

| SHIPMENT | DHL.TNT.UPS.FEDEX. EMS.SF EXPRESS |

| MOQ | 10 Pieces |

| Precision | High Speed Precision |

| Packing | 10pcs/ Box |

Frequently Asked Questions

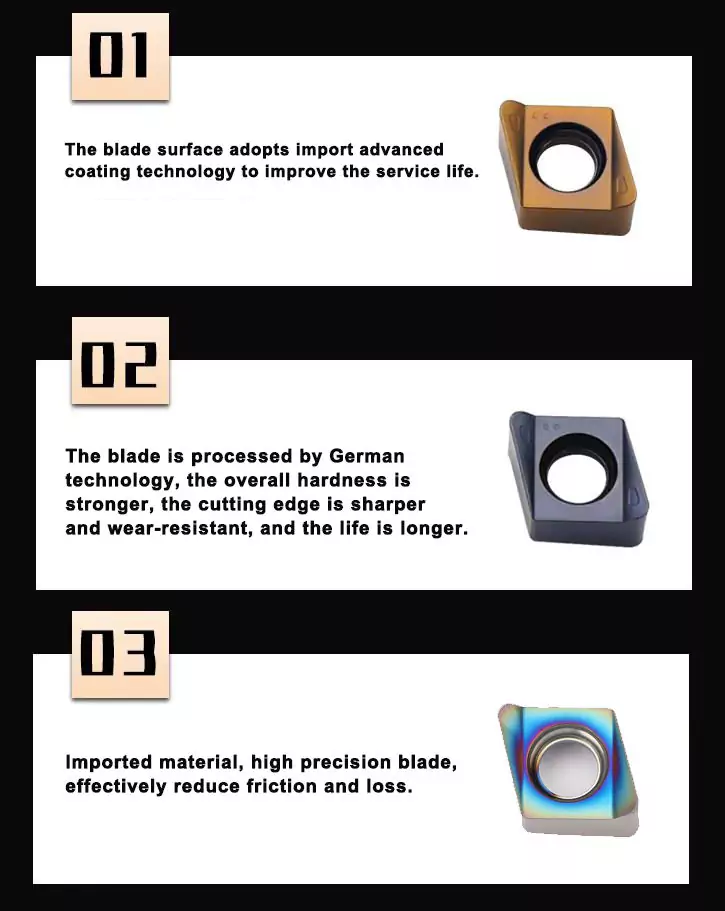

The milling cutter inserts from PROCNCTOOL are primarily made of high-quality tungsten carbide. Tungsten carbide is chosen for its exceptional hardness and wear resistance, making it suitable for demanding milling operations. It provides a balance of toughness and durability, ensuring that the inserts can maintain their cutting edge even under high-stress conditions. Additionally, the inserts may contain cobalt as a binder, enhancing their strength and performance in various milling applications.

The lifespan of milling cutter inserts depends on several factors including the material being machined, the cutting conditions, and the specific application. Generally, high-quality tungsten carbide inserts can last for several hours of continuous use. For example, in optimal conditions, an insert might last between 2 to 4 hours in high-speed milling operations. Proper maintenance and usage can extend this lifespan, ensuring consistent performance and reducing the frequency of replacements.

PROCNCTOOL offers milling cutter inserts with various advanced coatings to enhance performance and durability. Common coatings include:

- Titanium Nitride (TiN): Increases hardness and wear resistance.

- Titanium Carbonitride (TiCN): Provides superior wear resistance and reduces friction.

- Titanium Aluminum Nitride (TiAlN): Suitable for high-speed applications, offering excellent thermal stability.

- Aluminum Chromium Nitride (AlCrN): Known for high hardness and oxidation resistance.

These coatings help reduce tool wear, increase cutting speeds, and improve overall efficiency, making them suitable for demanding industrial applications.

Yes, the milling cutter inserts from PROCNCTOOL are versatile and can be used for both roughing and finishing operations. The inserts are designed with specific geometries and coatings that allow them to perform efficiently in different stages of the milling process. For roughing, they can remove large amounts of material quickly, while for finishing, they provide a smooth and precise surface finish. Selecting the appropriate insert geometry and coating ensures optimal performance for both types of operations.

The recommended cutting speed and feed rate for milling cutter inserts vary depending on the material being machined and the specific insert type. Generally, for tungsten carbide inserts with coatings like TiN or TiAlN, cutting speeds can range from 100 to 250 meters per minute (m/min) for steel and 300 to 500 m/min for aluminum. The feed rate should be adjusted based on the desired surface finish and material hardness, typically ranging from 0.05 to 0.2 millimeters per tooth (mm/tooth). Always refer to the manufacturer’s guidelines for optimal performance.

Yes, the milling inserts featured on thePROCNCTOOL website are designed to be suitable for high-speed machining operations. These inserts are typically made from materials like carbide or cermet, which are known for their excellent heat resistance and wear properties. Carbide inserts, for instance, can withstand higher cutting speeds compared to traditional tool materials like high-speed steel. The inserts are engineered with specific geometries and coatings that enhance their performance at elevated speeds, ensuring efficient material removal while maintaining dimensional accuracy and surface finish. It’s advisable to consult the manufacturer’s recommendations regarding the maximum permissible cutting speeds for different materials to optimize tool life and machining efficiency.

Yes, these inserts are versatile and can be used on both ferrous and non-ferrous materials. Inserts are available with various geometries, coatings, and grades tailored to specific machining requirements across a wide range of materials. For ferrous materials such as steel, inserts with tough substrates and wear-resistant coatings are utilized to withstand the high temperatures and abrasion encountered during machining. On the other hand, for non-ferrous materials like aluminum, inserts with sharp cutting edges and optimized chip breakers are preferred to ensure efficient chip evacuation and minimize built-up edge formation. Manufacturers provide detailed guidelines and recommendations for selecting the appropriate insert grade and geometry based on the specific material being machined, ensuring optimal performance and tool life.

The hardness rating of milling inserts varies depending on the material and grade used in their construction. Typically, inserts are made from materials like tungsten carbide, which has a hardness range of approximately 1500 to 2500 HV (Vickers hardness). Cermet inserts, another common material choice, have a hardness ranging from about 1200 to 1800 HV. These high hardness values contribute to the inserts’ ability to withstand the mechanical and thermal stresses encountered during machining processes. Harder inserts are generally more resistant to wear and deformation, ensuring longer tool life and consistent machining performance. Manufacturers provide detailed specifications and datasheets outlining the hardness ratings of their inserts, helping users select the appropriate insert for specific machining applications and materials.

Yes, PROCNCTOOL provides comprehensive instructional materials to guide users in effectively utilizing their milling inserts. These materials typically include user manuals, technical datasheets, cutting parameter recommendations, and application guides. The manuals offer insights into insert selection, machining strategies, and maintenance practices to optimize performance and extend tool life. Additionally, online resources such as video tutorials and machining calculators may be available to assist users in setting cutting parameters like cutting speed, feed rate, and depth of cut for various materials and machining conditions. Access to these instructional resources ensures that operators can maximize the efficiency and productivity of their machining operations while minimizing setup time and errors.

Yes, these milling inserts are designed to be compatible with a wide range of metals, including aluminum and stainless steel. Inserts are available in various grades and geometries tailored to specific material characteristics and machining requirements. For milling aluminum, inserts with sharp cutting edges and optimized chip breakers are utilized to facilitate efficient chip evacuation and prevent built-up edge formation. Stainless steel machining, on the other hand, demands inserts with tough substrates and wear-resistant coatings to withstand the high cutting forces and temperatures generated during the process. Manufacturers provide detailed recommendations for selecting the appropriate insert grade, geometry, and cutting parameters based on the specific metal being machined, ensuring optimal performance, surface finish, and dimensional accuracy in diverse machining applications.

Reviews

There are no reviews yet.