Frequently Asked Questions

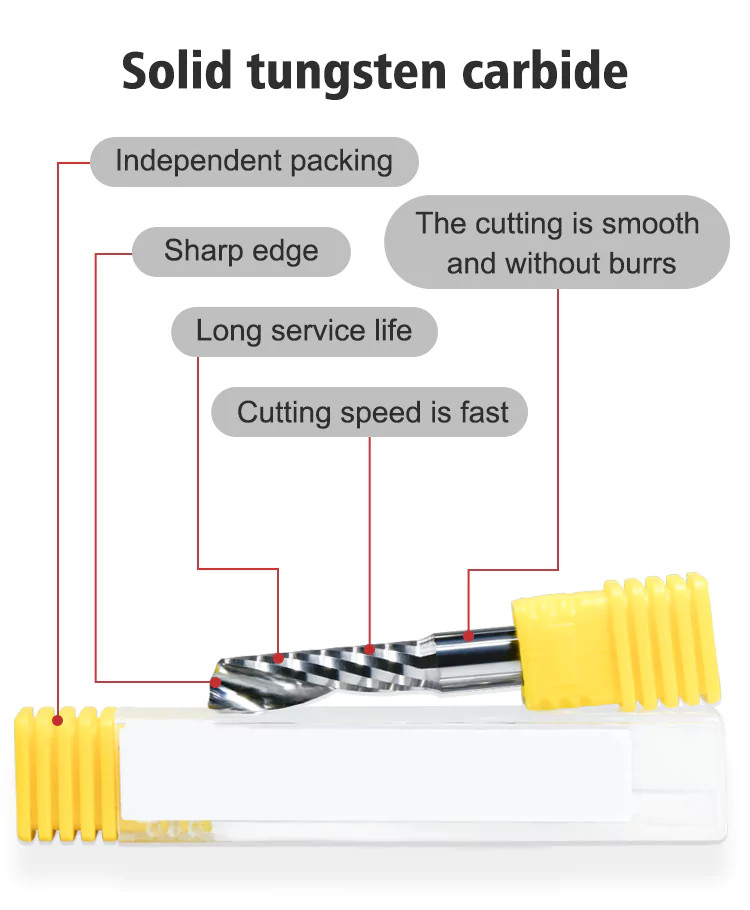

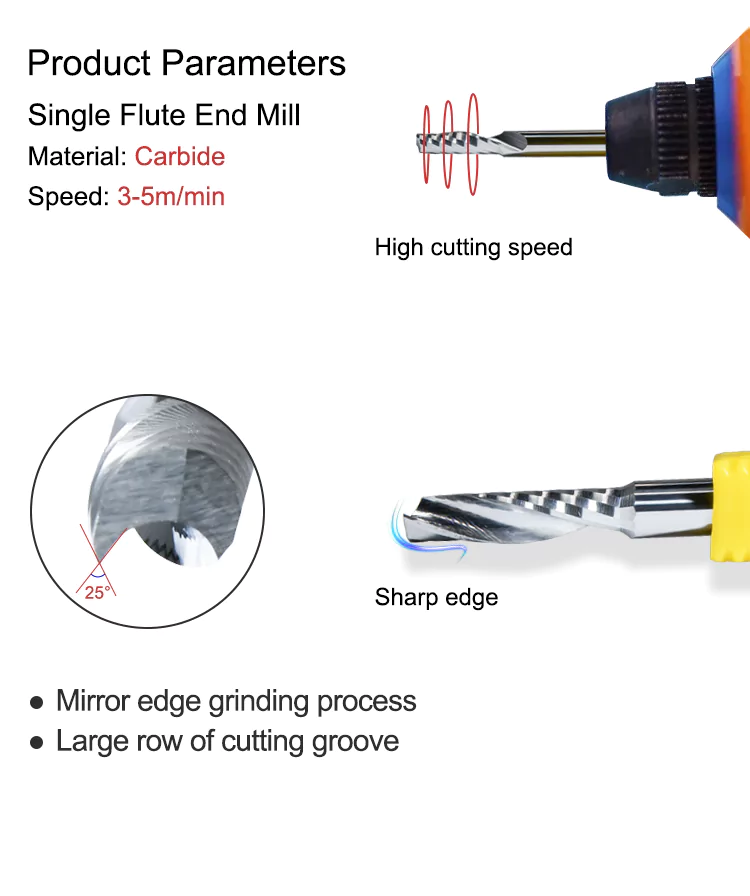

Woodworking end milling cutters are typically made from high-speed steel (HSS) or carbide. High-speed steel cutters are known for their durability and ability to withstand high temperatures without losing hardness, making them suitable for a variety of woodworking tasks. Carbide cutters, on the other hand, are preferred for their exceptional hardness and wear resistance, offering a longer lifespan and superior performance, especially in high-speed applications or when cutting harder woods.

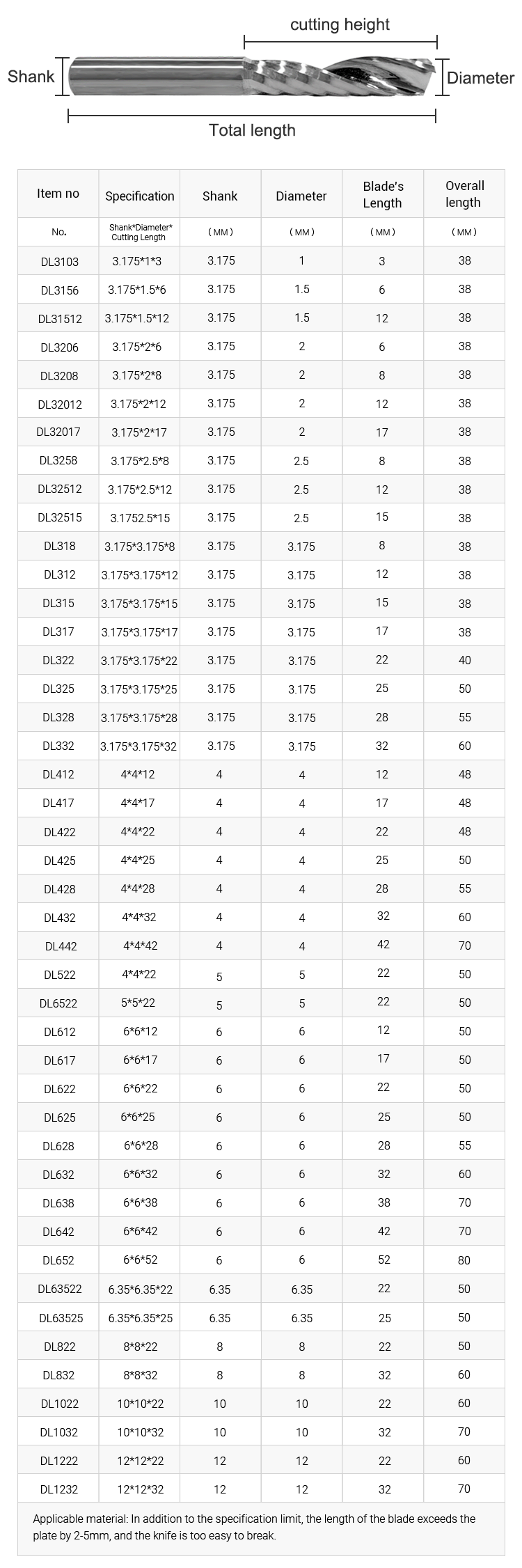

End milling cutters come in a wide range of sizes to accommodate different woodworking needs. Common sizes vary in cutting diameter from 1/8 inch (3.175 mm) to 1 inch (25.4 mm) or more, with cutting lengths ranging from a few millimeters to several inches. The shank diameter also varies, typically matching common tool holder sizes like 1/4 inch, 1/2 inch, or 6 mm, 12 mm. Specific size availability can depend on the manufacturer and the intended application of the cutter.

Yes, woodworking end milling cutters can be used on both hardwood and softwood. However, the choice of cutter material and design is crucial for optimal performance. Carbide cutters are generally better suited for hardwoods due to their hardness and wear resistance, while HSS cutters can efficiently handle softwoods. Additionally, the cutter’s flute design and cutting geometry should be matched to the type of wood to ensure smooth, efficient cutting and to minimize wear.

The lifespan of a woodworking end milling cutter depends on several factors, including the material it’s made from, the type of wood being cut, the cutting conditions (such as speed and feed rate), and how well the cutter is maintained. Generally, carbide cutters have a longer lifespan compared to HSS cutters due to their superior hardness and wear resistance. Under typical conditions, a carbide cutter can last several times longer than an HSS cutter. Regular maintenance, such as proper cleaning and sharpening, can also extend the cutter’s lifespan.

Choosing the right end milling cutter for your project involves considering several factors:

- Material: Choose carbide for hardwoods and high-wear applications, and HSS for softwoods and general use.

- Size: Select a cutter with the appropriate diameter and cutting length for your workpiece and the detail required.

- Flute Design: Use up-cut flutes for good chip removal and down-cut flutes for cleaner top surfaces. Compression cutters combine both to minimize tear-out.

- Cutting Geometry: Match the cutting edge geometry to the type of wood and the desired finish.

- Machine Compatibility: Ensure the shank size matches your router or CNC machine collet.

- Project Specifics: Consider the intricacies of your project, such as the need for plunge cutting, slotting, or edge finishing.

Straight milling cutters have flutes that run parallel to the axis of the cutter, providing a straightforward cutting edge that is effective for simple cutting tasks and operations requiring minimal tear-out. They are commonly used for making straight cuts and are easier to sharpen.

Spiral milling cutters, on the other hand, have flutes that twist around the cutter’s axis. This design allows for a smoother cutting action, better chip evacuation, and reduced vibration. Spiral cutters can be either up-cut, down-cut, or compression:

- Up-cut: Efficiently removes chips upwards, ideal for deeper cuts and improved material removal.

- Down-cut: Pushes chips downwards, resulting in a cleaner top surface with less tear-out.

- Compression: Combines both up-cut and down-cut flutes, minimizing tear-out on both top and bottom surfaces, making them ideal for laminated materials.

Proper maintenance and sharpening of an end milling cutter involve several steps:

- Cleaning: After each use, clean the cutter to remove resin, pitch, and wood debris. Use a specialized cleaning solution and a brush to ensure all residues are removed.

- Inspection: Regularly inspect the cutter for signs of wear, such as dull edges or chips. Replace the cutter if significant damage is detected.

- Sharpening: When the cutter becomes dull, sharpen it using a diamond wheel or professional sharpening service. Ensure the original cutting angles are maintained to preserve performance.

- Storage: Store cutters in a dry, clean environment, ideally in protective cases or holders to prevent damage to the cutting edges.

- Usage: Avoid excessive feed rates and ensure the cutter is properly secured in the tool holder to minimize stress and wear.

Yes, woodworking end milling cutters are designed to be used with CNC machines. They are specifically crafted to handle the precise and repetitive tasks required in CNC machining. When selecting a cutter for CNC use, ensure that the shank size matches the collet of your CNC machine and that the cutter’s specifications align with the material and type of cutting you plan to perform. Additionally, using the correct feeds and speeds as recommended by the cutter manufacturer will optimize performance and tool life.

The cutting diameter and length of an end milling cutter can vary widely depending on the specific model and intended application. Common diameters range from 1/8 inch (3.175 mm) to 1 inch (25.4 mm), while cutting lengths can range from a few millimeters to several inches. For precise specifications, refer to the manufacturer’s product details or datasheets, which provide exact measurements for each cutter model.

Using end milling cutters safely involves adhering to several important precautions:

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and appropriate clothing to protect against flying debris and noise.

- Secure Workpiece: Ensure the workpiece is firmly secured to prevent movement during cutting, which can lead to accidents or poor-quality cuts.

- Tool Installation: Make sure the cutter is properly installed in the tool holder or spindle, and check that it is tightly secured.

- Machine Setup: Verify that the machine settings, such as speed and feed rate, are correctly configured for the cutter and material.

- Clear Area: Keep the work area clean and free of obstructions. Ensure that there are no loose objects that could interfere with the cutting operation.

- Operational Awareness: Always stay alert and focused while operating the machine. Avoid distractions and never leave the machine running unattended.

- Maintenance: Regularly inspect and maintain both the cutter and the machine to ensure they are in good working condition.

Reviews

There are no reviews yet.