Surface profilometers play a pivotal role in industrial processes and quality control by providing precise measurements of surface textures and topographies. These instruments are integral to various fields, from materials science to engineering, where understanding the surface characteristics of a material can significantly impact its performance and application.

Definition of a Profilometer

A profilometer is an instrument used to measure a surface’s profile to quantify its roughness. It works by moving a sensor across the surface and recording variations in height. This data is then processed to produce a detailed map of the surface structure, showcasing its peaks, valleys, and overall texture. These measurements are crucial in determining the efficiency and suitability of a material for specific applications, particularly in manufacturing where surface quality can affect everything from aesthetic appeal to functional performance.

Importance of Surface Profilometers

Surface profilometers are essential because they provide detailed and accurate readings of surface textures and profiles, which are critical in research and development, quality control, and production processes. By understanding the surface characteristics, engineers and scientists can predict how materials will behave under different conditions, ensuring that they meet the required standards for performance and durability. Profilometry, therefore, enhances product quality and reliability, leading to better performance and longevity.

Key Terms: Anisotropic and Isotropic Surfaces

Key to profilometry are the concepts of anisotropic and isotropic surfaces. Anisotropic surfaces have directional properties that change depending on the direction in which they are measured, whereas isotropic surfaces have uniform properties regardless of the measurement direction. Understanding these properties can inform decisions on material suitability for specific applications, as different textures may affect friction, lubrication, and wear in different ways.

What is a Profilometer or Surface Profilometer?

A profilometer or surface profilometer is a sophisticated device designed to capture the minutiae of a surface’s typography. It can measure the topographical features with remarkable precision, including their dimensions and textural variations. This data is invaluable in numerous applications, from ensuring the smooth operation of mechanical parts to enhancing the tactile appeal of consumer products.

Topographical Characterization

Topographical characterization involves detailing a surface’s three-dimensional features to understand its geometry and texture.

Primary Form

The primary form refers to the main shape of the surface, capturing macro-geometry without the fine details. This aspect is crucial for assessing the overall profile of a component and ensuring it conforms to its design specifications.

Sub-Micron Textural Variations

Sub-micron textural variations include the micro-geometry that highlights finer surface details. These variations can significantly influence the functionality of a component, such as how well it resists wear or adheres to other materials.

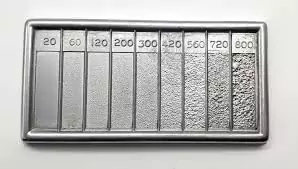

Dimensional Fractality and Surface Roughness

Dimensional fractality and surface roughness are critical parameters measured by a surface profilometer. Dimensional fractality represents complex surface patterns that persist across different scales, while surface roughness quantifies the variations in surface height at a microscopic level. Both parameters are essential for predicting and controlling mechanical properties and finishing processes.

Impact on Physical Properties

Directional Lay or Pattern

The directional lay or pattern is the dominant texture running across a surface. The orientation and type of this lay can affect the material’s interaction with other substances, impacting friction, wear, and lubrication.

Effects on Material Properties

Surface characteristics directly affect material properties like strength, fatigue resistance, and aesthetic qualities. Precise surface measurements can guide treatment processes like coating and polishing to enhance these properties.

Types of Surface Profilometers

Surface profilometers come in various types, each suited to different applications and accuracy requirements.

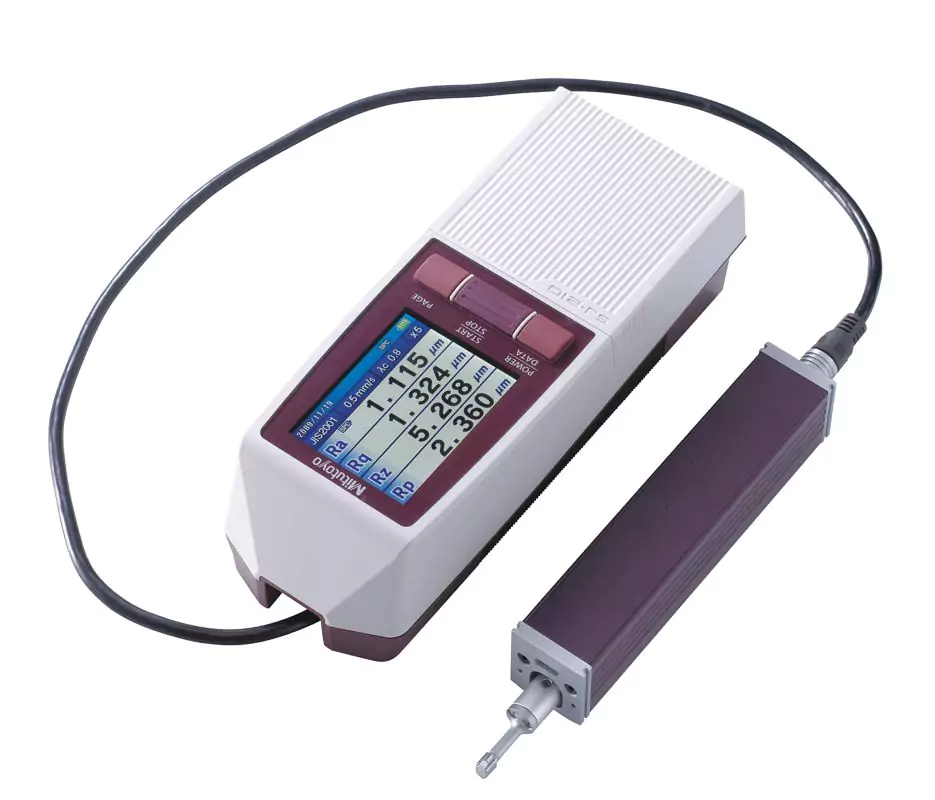

Stylus Profilometers

Stylus profilometers use a physical stylus to trace the surface and record height variations. They are effective for detailed measurements and can capture data over various scales.

Example: PGI Novus Surface Profilometer

The PGI Novus is an advanced stylus profilometer known for its high precision and large measurement range. It is widely used in industries requiring meticulous surface analysis, from automotive to aerospace sectors.

Optical Surface Profilometers

Optical profilometers use light, usually in the form of lasers or white light, to measure the surface without physical contact. They are ideal for delicate surfaces where contact might cause damage.

Example: PGI Matrix Optical Profilometer

The PGI Matrix Optical Profilometer provides non-contact measurement, allowing for rapid and accurate surface analysis. Its applications are diverse, including semiconductor manufacturing and biomedical engineering.

3D Non-Contact Surface Profilometers

3D non-contact profilometers offer comprehensive surface characterization without touching the material, making them suitable for fragile or soft surfaces.

Example: LUPHOScan HD 3D Non-Contact Profilometer

The LUPHOScan HD is renowned for its high-definition 3D surface mapping capabilities. It offers unparalleled accuracy and speed in capturing surface topographies, crucial for industries like optics and precision engineering.

Understanding, measuring, and analyzing surface texture through profilometry is indispensable for numerous industrial applications. Whether using stylus, optical, or 3D non-contact methods, surface profilometers provide critical insights that drive innovation and quality across various sectors.

Working Principles of Profilometers

Understanding the working principles of profilometers is crucial for leveraging their capabilities in various applications. These principles ensure that accurate, reliable data is collected across different scales and conditions, providing insights necessary for quality control and research.

High-Precision Data Acquisition

The hallmark of a surface profilometer lies in its ability to acquire high-precision data. This is achieved through advanced sensors and data processing algorithms that can detect and record minute variations in surface heights.

Nano-, Micro-, and Macroscale Measurements

A well-designed surface profilometer can perform measurements on the nano-, micro-, and macro-scales. At the nanoscale, profilometers capture atomic-level surface variations, which are crucial in semiconductor and nanotechnology industries. At the microscale, they provide detailed texture analysis that impacts material behavior in mechanical and biological systems. At the macroscale, measurements help assess overall shape and contour, essential for automotive and aerospace components.

Contact Methods

Contact profilometry involves physical interaction between the profilometer’s stylus and the sample surface. This method is advantageous in scenarios where the material’s mechanical properties need to be assessed.

Contact Surface Profilometer

A contact surface profilometer uses a fine stylus that traverses the material’s surface, recording height variations physically. The stylus is often diamond-tipped to ensure durability and minimal wear over prolonged usage.

Physical Contact with Substrate

By making direct physical contact with the substrate, the stylus can measure even the smallest deformations and variations in height. This interaction is especially useful for capturing accurate roughness profiles in materials with significant textural features.

Measuring Surface Deformations and Variations

Contact profilometers excel in measuring surface deformations and variations, providing quantitative data that helps in understanding material properties like hardness, elasticity, and wear resistance. This data is vital for predicting material behavior under mechanical loads and during interactions with other surfaces.

Advantages of Contact Profilometry

Contact profilometry offers unique advantages in specific applications, making it a preferred choice in many industrial and research settings.

Suitable for Roughness, Waviness, and Form Measurements

A contact surface profilometer is particularly adept at measuring surface roughness, waviness, and form. These measurements are critical in applications where surface texture directly affects the functionality, like in mechanical seals, bearings, and gears.

Resistance to Optical Interference and Lubricating Elements

Unlike optical methods, contact profilometry is less susceptible to interference from optical reflections or surface contaminants like lubricating elements. This resistance ensures that the data collected is accurate and reliable, even in less-than-ideal conditions.

Non-Contact Methods

Non-contact profilometry utilizes optical techniques to measure surface features without any physical contact, making it ideal for delicate or soft surfaces that could be damaged by a stylus.

Optical Acquisition Methodologies

Optical methods often employ lasers, white light, or electron beams to scan surfaces and obtain measurements.

Confocal Microscopy

Confocal microscopy is a powerful optical acquisition technique used in non-contact profilometers. It provides high-resolution images by focusing light from a laser through a pinhole to eliminate out-of-focus light. This method captures precise 3D topographical information and is widely used in biological and materials sciences.

Electron Microscopy

Electron microscopy, particularly Scanning Electron Microscopy (SEM), allows for surface measurements at incredibly high resolutions. By using a focused beam of electrons, SEM can provide detailed topographical information down to the nanometer scale, making it indispensable in fields like electronics and materials science.

Advantages of Non-Contact Profilometry

Non-contact profilometry offers several benefits that make it suitable for various high-precision applications.

Low Invasiveness

The primary advantage of non-contact profilometry is its non-invasiveness. It avoids any physical interaction with the surface, preventing potential damage or alteration to delicate, soft, or highly reflective surfaces. This feature is particularly beneficial in quality control for semiconductor wafers, thin films, and biomedical devices.

Improved Measurement Speeds

Non-contact methods typically offer faster measurement speeds compared to contact profiling. The rapid data acquisition capabilities of optical devices make them suitable for real-time monitoring and control in automated manufacturing processes, thereby enhancing productivity and efficiency.

Applications of Surface Profilometers

The versatility of surface profilometers makes them invaluable across numerous industrial and scientific domains. Their ability to provide precise surface measurements ensures that end products meet stringent quality standards and perform reliably in their intended applications.

Process Control Applications

In process control, surface profilometers are essential for monitoring and maintaining the quality of mechanically mating surfaces. This includes components that interact through movement or physical contact and require precise surface profiles to function effectively.

Assessing Mechanically Mating Surfaces

Surface profilometers play a crucial role in assessing surfaces of components that mate mechanically, ensuring proper fit and function.

Shafts and Bearings

In the case of shafts and bearings, the surface roughness and roundness are critical for minimizing friction and wear. Surface profilometers can accurately measure these parameters to ensure longevity and reliable performance.

Friction-Induced Defects

Profilometers help identify friction-induced defects such as scratches and wear tracks. Understanding these defects allows engineers to improve lubrication systems and surface treatments, enhancing the durability and efficiency of mechanical components.

Optical Lenses

In optics, the quality of the lens surface directly impacts its performance. Surface profilometers are used to ensure that lenses meet precise specifications, whether for consumer cameras or advanced scientific instruments.

Monitoring Batch-to-Batch Consistency

Achieving batch-to-batch consistency in optical lens manufacturing is vital for maintaining quality. Surface profilometers provide the detailed surface measurements necessary for monitoring and controlling the production process, ensuring that each lens produced adheres to rigorous standards.

Applications in Various Scales

From microscopic objectives to large astronomical telescopes, surface profilometers ensure that lenses perform optimally at all scales. By precisely measuring surface aberrations, these instruments help in designing lenses with minimal optical distortion.

Other Industry Applications

Beyond the previously mentioned applications, surface profilometers are invaluable in various other industries, contributing to product quality and performance improvements.

Reducing Uncertainties in Surface Topographies

Profilometry significantly reduces uncertainties in surface topographies by providing consistent and accurate measurements. This data is essential in fields like aerospace, automotive, and electronics, where precise surface characteristics can dramatically affect overall performance and reliability.

Enhancing Precision in Product Performance

By offering detailed surface analysis, surface profilometers help manufacturers fine-tune production processes, leading to enhanced precision in product performance. This enhancement is particularly evident in high-tech industries where even minor surface imperfections can lead to significant functional issues.

In summary, surface profilometers are indispensable tools in modern industry and research. They provide high-precision surface measurements using various methodologies, each suited to specific needs and applications. Whether employing contact or non-contact methods, these instruments deliver critical data that drive innovation and quality in numerous sectors, from manufacturing to materials science.

Recap of Profilometer Functions and Benefits

Surface profilometers play a critical role in modern industries, providing detailed insights into surface characteristics that are key to ensuring product quality, performance, and longevity. These instruments, whether contact or non-contact profilometers, allow for precise surface measurements, catering to a wide range of applications from material science research to quality control in production lines.

Precision and Accuracy

One of the primary benefits of using a profilometer is its ability to deliver high-precision and accurate surface measurements. This ensures that the surfaces of mechanical components meet specified tolerances, which is vital for their performance and durability. For instance, in the automotive industry, accurate surface texture measurements can prevent premature wear and tear of engine parts, leading to longer lifespans and more reliable products.

Diverse Application Range

Surface profilometers are versatile tools that find applications in various industries such as aerospace, biomedical engineering, optics, and electronics. Each industry has unique requirements for surface characteristics, and profilometers are adaptable to these needs, providing detailed data essential for optimizing processes and enhancing product performance.

Non-Destructive Testing

Another significant advantage of many surface profilometers is their non-destructive testing capability. Non-contact methods, in particular, can analyze delicate surfaces without causing any damage, making them ideal for inspecting high-precision optics, semiconductor wafers, or biomedical implants. This feature ensures the integrity of the components being tested while still providing crucial surface detail information.

Enhanced Product Development

Profilometry is integral to research and development processes. By understanding surface characteristics at various scales, engineers and researchers can innovate and improve product designs. This detailed surface analysis helps in identifying potential issues early, reducing the time and cost associated with iterative testing and redesigning.

Future Prospects in Metrology and Industry Applications

As technology advances, the role of profilometers in metrology and industry is expected to grow, driven by increasing demand for precision and efficiency. Emerging trends and applications will likely shape the future landscape of profilometry, making it more critical than ever for industries to stay abreast of these developments.

Integration with Advanced Manufacturing Processes

Future surface profilometers are anticipated to integrate more seamlessly with advanced manufacturing processes such as additive manufacturing and automated production lines. Real-time surface measurement capabilities will enable immediate adjustments to ensure consistent product quality, thereby minimizing waste and increasing overall production efficiency.

Enhanced Data Analytics and Machine Learning

The integration of machine learning and advanced data analytics with profilometry will further revolutionize surface measurement techniques. These technologies will allow for more sophisticated data interpretation, enabling predictive maintenance and advanced quality control measures. For example, by analyzing surface data trends, manufacturers could predict when machinery components are likely to fail and take preemptive action to avoid downtime.

Increased Use in Nanotechnology and Biotechnology

As nanotechnology and biotechnology fields expand, the demand for ultra-precise surface measurements will grow. Surface profilometers capable of measuring at the nanoscale will be critical in developing new materials and devices in these cutting-edge sectors. Applications in creating advanced medical implants, developing nanomaterials with specific properties, and ensuring the precision of microscopic components in electronics will drive innovations in profilometry technology.

Sustainability and Eco-Friendly Practices

Future advancements in profilometry are also expected to support more sustainable and eco-friendly manufacturing practices. By enabling precise control over surface finishes, profilometers can help reduce the need for excessive material usage and minimize environmental impact. Additionally, the detailed data provided by these instruments can help optimize recycling processes and enhance the lifecycle management of industrial components.

In conclusion, surface profilometers are indispensable tools in the realm of metrology and industrial applications. Their ability to deliver precise, reliable surface measurements ensures high-quality outputs and aids in diverse applications from scientific research to advanced manufacturing. As industries evolve, the role of profilometers will become increasingly pivotal, driven by technological advancements and the continuous quest for improved efficiency and sustainability. Staying updated with the latest profilometer technologies and methodologies is crucial for industries aiming to maintain a competitive edge and achieve excellence in product quality and performance.