Introduction to Milling Tools

Milling tools are indispensable components in the world of manufacturing and machining. Designed to effectively remove material and shape workpieces, these tools come in a variety of types and functionalities to achieve specific results. Milling tools are crucial for performing tasks such as drilling, slotting, shaping, contouring, and engraving. Understanding these tools is vital for manufacturers and machinists looking to achieve optimal performance and precision in their projects.

Importance of Understanding Milling Tools

Knowledge of milling tools and their applications is vital for ensuring efficiency and precision in manufacturing processes. Using the right tool for the job can dramatically reduce production times, enhance the quality of the finished product, and minimize tool wear and tear. Conversely, using the wrong tool can result in poor performance, increased costs, and substandard products. Therefore, a comprehensive grasp of milling tools and their uses is essential for anyone involved in machining.

Purpose of the Blog

In this blog, we aim to demystify two specific types of milling tools: Roughing End Mills and Finishing End Mills. By providing clear definitions, key characteristics, and detailed comparisons, we hope to guide our readers in selecting the appropriate tool for their needs.

Target Audience

This article is targeted towards manufacturers, machinists, engineers, and hobbyists who are involved in machining and manufacturing. Whether you’re a seasoned professional or a beginner, this guide will provide valuable insights into selecting the right milling tools for your projects.

Objectives

The main objective of this blog is to explain the differences between Roughing End Mills and Finishing End Mills. We will delve into the features, applications, and advantages of each tool, helping you make an informed decision on which tool to use for specific tasks.

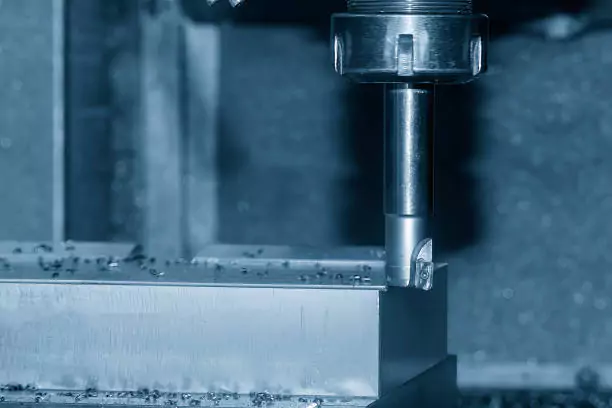

What is an End Mill?

Definition

An end mill is a type of cutting tool used in milling applications. Unlike a drill bit that cuts axially to create cylindrical holes, an end mill cuts laterally with its cutting edges located on both the periphery and face.

Comparison with Drill Bits

While both end mills and drill bits are used for cutting, their functions and applications are distinct. Drill bits are primarily used for creating cylindrical holes by cutting straight down into the material. In contrast, end mills can cut in various directions, including axial and lateral movements, making them versatile tools for a wide range of machining tasks.

Functions and Uses

End mills are commonly used for various machining tasks such as cutting slots, creating complex profiles, contouring surfaces, and engraving intricate designs. Their ability to cut in multiple directions allows for more complex and precise machining operations compared to drill bits.

Types and Variations

End mills are available in several types and variations, each designed for specific materials and tasks. Understanding these types is crucial for selecting the right tool.

Types Based on Material

End mills can be made from a variety of materials, including high-speed steel (HSS), carbide, and cobalt. Carbide end mills are particularly popular due to their hardness and resistance to wear, making them suitable for high-speed applications and harder materials.

Types Based on Flute Shape

End mills also vary based on the shape and number of flutes. Common types include two-flute, three-flute, and four-flute end mills, each offering different advantages. For example, two-flute end mills provide better chip clearance, making them ideal for softer materials, while four-flute end mills offer a smoother finish and are suited for harder materials.

Common Applications

End mills have a wide range of applications in various industries. Here are some common uses:

Slotting

Slotting involves creating channels or slots in a workpiece. End mills are highly effective for this task, providing clean and precise cuts.

Profiling

Profiling refers to shaping the edges or surfaces of a workpiece into a specific profile or contour. End mills are ideal for this purpose due to their lateral cutting capabilities.

Contouring

Contouring involves creating intricate designs on the surface of a workpiece. End mills with different flute shapes and sizes can achieve various contouring effects.

Engraving

Engraving is the process of etching designs or text onto a surface. End mills with fine cutting edges are perfect for this delicate task, allowing for precise and detailed engravings.

What is a Roughing End Mill?

Definition and Characteristics

A Roughing End Mill, often referred to as a hog mill, is engineered specifically for rapid material removal. Characterized by its serrated cutting edges, this tool efficiently grinds through large volumes of material, making it ideal for initial roughing cuts in machining operations.

Structure and Design

Roughing End Mills possess a unique structure that differentiates them from other end mills. They feature a serrated cutting edge that breaks up material into small chips, reducing heat buildup and tool wear. Their design typically includes a higher helix angle and a sturdy core to endure heavy cuts.

Materials Used

These end mills are typically constructed from materials such as high-speed steel (HSS) and carbide. Carbide roughing end mills are preferred for their exceptional hardness and wear resistance, especially when working with tougher materials.

Function and Purpose

The primary purpose of a Roughing End Mill is to remove large quantities of material quickly. This process prepares the workpiece for more detailed final operations.

Rapid Material Removal

Due to their aggressive cutting action, Roughing End Mills excel at removing significant amounts of material with each pass. This efficiency reduces the overall machining time and makes them a preferred choice for high-volume production environments.

Coarse Tooth Variants

Coarse tooth variants of Roughing End Mills are designed for extremely rapid material removal. These tools are suited for removing heavy stock and are often used in the initial stages of milling operations.

Fine Tooth Variants

Fine tooth variants offer a balance between material removal rate and surface finish. While not as aggressive as their coarse counterparts, they still remove material quickly and leave a more refined finish, making subsequent finishing operations easier.

Applications

Roughing End Mills find applications in various industries and materials.

Low to Medium Carbon Steel

These tools are highly effective for machining low to medium carbon steel, where rapid material removal is essential.

Alloy Steel

Roughing End Mills are also suitable for alloy steel, handling the tougher material efficiently without compromising on the speed of material removal.

High-Temperature Alloys and Stainless Steel

When it comes to high-temperature alloys and stainless steel, Roughing End Mills demonstrate exceptional performance. Their design allows them to tackle the hardness of these materials while maintaining efficient material removal rates.

Advantages

Efficiency in Heavy Cuts

One of the primary advantages of Roughing End Mills is their efficiency in making heavy cuts. Their design minimizes cutting forces and reduces the likelihood of tool deflection, ensuring consistent performance.

Lower Cutting Pressures

The serrated design of Roughing End Mills breaks materials into smaller chips, which translates to lower cutting pressures. This characteristic helps prolong tool life and reduces the stress on machining equipment.

Variants

Pitch Types

Roughing End Mills are available in different pitch types to cater to specific machining needs. Variable pitch designs help reduce vibrations and improve overall tool stability during heavy cuts.

Length Variations

These end mills come in various lengths to accommodate different cutting depths and workpiece sizes. Selecting the appropriate length ensures that the tool can perform effectively without excess stress.

Diameter Sizes

Roughing End Mills are available in a wide range of diameter sizes, allowing for flexibility in machining operations. The chosen diameter can significantly impact the material removal rate and the overall efficiency of the machining process.

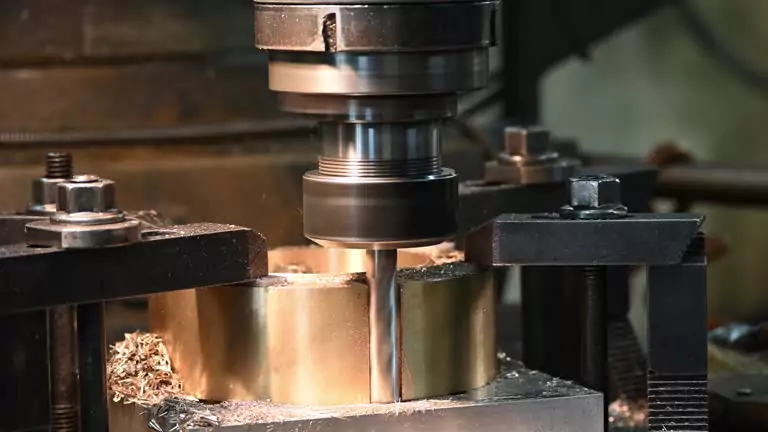

What is a Finishing End Mill?

Definition and Characteristics

A Finishing End Mill is specifically designed to provide a high-quality surface finish and precise dimensional accuracy. Unlike Roughing End Mills, these tools are used in the final phases of machining to achieve a superior finish and detailed features.

Structure and Design

Finishing End Mills have smooth cutting edges and a higher number of flutes compared to Roughing End Mills. This design allows for finer cuts and reduced tool marks on the workpiece surface.

Materials Used

Finishing End Mills are typically made from high-speed steel (HSS), carbide, and sometimes coated with materials like titanium nitride (TiN) to enhance performance and lifespan. Carbide variants are particularly favored for their hardness and wear resistance.

Function and Purpose

The primary purpose of a Finishing End Mill is to create a fine surface finish and adhere to exact dimensional tolerances. They are used after the bulk of the material has been removed by other milling tools.

High Surface Quality

Finishing End Mills excel in providing high surface quality. The multiple flutes and sharper edges result in smoother cuts, which are essential for applications requiring a refined surface finish.

Dimensional Accuracy

Precision is critical in the final stages of machining, and Finishing End Mills are designed to meet tight tolerances. Their accurate cuts ensure that the dimensions of the workpiece stay within the required specifications.

Applications

Finishing End Mills are indispensable in a variety of applications that require a smooth finish and precise dimensions.

Side Milling Operations

In side milling, the Finishing End Mill is used to make light passes along the side of the workpiece, refining the surface and ensuring dimensional accuracy. This operation is crucial in applications like mold-making, aerospace components, and precision engineering.

Advantages

High Surface Finish

One of the standout benefits of using Finishing End Mills is the high-quality surface finish they produce. This feature is crucial in applications where aesthetics and smooth surfaces are paramount.

Precise Tolerances

Finishing End Mills offer the advantage of maintaining precise tolerances. This ability is particularly important in industries where exact dimensions and specifications are crucial, such as aerospace and medical device manufacturing.

Variants

Flute Configurations

Finishing End Mills come with various flute configurations to suit different materials and cutting conditions. For example, higher flute counts provide a smoother finish, while lower flute counts can be used for materials that require more chip clearance.

Helix Angles

The helix angle of a Finishing End Mill affects its cutting action and performance. Tools with higher helix angles offer enhanced cutting action, less chatter, and produce smoother surfaces.

Roughing vs. Finishing End Mill

Basic Differences

Understanding the fundamental distinctions between Roughing End Mills and Finishing End Mills is essential for selecting the right tool for your machining needs.

Purpose and Use

The primary difference lies in their purpose and use. Roughing End Mills are designed for rapid material removal during the initial stages of a project. In contrast, Finishing End Mills are used in the final stages to achieve high surface quality and precise dimensions.

Material Removal Rates

Roughing End Mills excel at high material removal rates, making them ideal for heavy-duty cutting and quick stock removal. Finishing End Mills, on the other hand, remove less material but provide a much finer finish.

Surface Quality

Roughing: Basic Shape and Large Material Removal

Roughing End Mills are intended for shaping the workpiece and removing large amounts of material. They leave a rough surface that will be refined in subsequent machining steps.

Finishing: Surface Quality and Accuracy

Finishing End Mills focus on the surface quality and accuracy of the finished piece. They provide a smooth, high-quality finish that meets stringent aesthetic and functional requirements.

Cutting Parameters

Feed Rate

Feed rate is a critical parameter in machining. Roughing End Mills work effectively with higher feed rates due to their aggressive material removal capabilities. Finishing End Mills, however, require lower feed rates to achieve a precise and smooth finish.

Depth of Cut

Depth of cut significantly affects tool performance and the quality of the finished product. Roughing End Mills can handle deeper cuts, allowing for rapid material removal. Finishing End Mills, conversely, perform better with shallower cuts to ensure a superior finish.

Tool Geometry

Impact on Surface Finish

The geometry of the tool significantly impacts the surface finish. Roughing End Mills, with their serrated edges, produce a rougher finish, whereas Finishing End Mills, with their smoother edges and higher flute counts, deliver a much finer finish.

Tool Longevity

Tool longevity is another critical factor. Roughing End Mills, designed for heavy-duty operations, are built to withstand the stresses of roughing cuts but may wear out faster due to the heavy material removal. Finishing End Mills, crafted for precision and smooth cuts, typically have a longer lifespan when used correctly for their intended purpose.

Understanding the distinct characteristics, purposes, and advantages of Roughing End Mills and Finishing End Mills is essential for anyone involved in machining. By selecting the appropriate tool for the job, machinists can achieve greater efficiency, precision, and quality in their projects.

Advantages of Roughing End Milling

Efficiency in Material Removal

High Feed Rate Capability

Roughing end mills are capable of operating at high feed rates, significantly enhancing the efficiency of material removal. This high feed rate capability results in the quick removal of large amounts of material, thereby reducing the overall machining time.

Bulk Material Removal

The design of roughing end mills allows them to handle bulk material removal with ease. They can cut through tough materials and remove substantial amounts of stock in a short amount of time, making them ideal for initial roughing operations.

Structural Stability

Rigidity During Operation

Roughing end mills offer excellent rigidity during operation due to their robust construction. This rigidity minimizes tool deflection, ensuring stable and accurate cuts even under heavy load conditions.

Reduced Vibration

The specialized tooth geometry of roughing end mills helps to reduce vibration during cutting. Reduced vibration not only improves the quality of the cut but also extends the tool life by preventing premature wear and tear.

Tool Longevity

Wear Resistance

Roughing end mills, made from durable materials like HSS or carbide, exhibit exceptional wear resistance. This durability ensures that these tools can withstand the rigorous demands of machining operations, leading to longer tool life and reduced tool replacement costs.

Breakdown of Finishing End Mills

Function of Finishing End Mill

Finishing end mills are designed for achieving high precision and fine surface finishes. They are typically used in the final stages of machining to refine the geometry of the workpiece and ensure tight tolerances. These end mills are crucial for delivering the desired finish and accuracy on the machined parts.

Characteristics & Features

Design Aspects

Finishing end mills usually feature a higher number of flutes (cutting edges), which allows for a smoother and finer finish. The increased number of flutes provides better surface contact and reduces the spacing between cutting edges, resulting in a superior finish.

Cutting Mechanism

The cutting mechanism of finishing end mills involves finer cuts with smaller chip formation. The precise and controlled removal of material leads to highly accurate dimensions and smooth surfaces, essential for final product quality.

Tool Composition

Finishing end mills are often made from high-quality materials such as carbide, which offers excellent wear resistance and the ability to maintain sharp cutting edges. The composition of these tools is tailored to maximize performance and achieve the best possible surface finish.

Advantages of Finishing End Milling

Precision

High Dimensional Accuracy

Finishing end mills offer high dimensional accuracy, ensuring that the final dimensions of the workpiece adhere closely to design specifications. This precision is critical in applications that require exact tolerances, such as in the aerospace or medical device industries. Utilizing finishing end mills helps in maintaining the fidelity of the material to the desired specifications.

Low Feed Rate

A low feed rate is a significant advantage of finishing end milling. The slower advancement of the cutting tool allows for greater control over material removal, enabling the production of finely tuned and highly accurate features. This controlled approach minimizes errors and enhances the overall quality of the finished product.

Surface Quality

Good Surface Finish

Finishing end mills are designed to produce an excellent surface finish on the workpiece. The high number of flutes and the refined cutting edges reduce the surface roughness, creating a polished and visually appealing final product. This is especially important in industries where surface quality is paramount, such as in the manufacture of consumer electronics or decorative items.

Extended Tool Life

The materials and coating technologies used in finishing end mills contribute to their extended tool life. By maintaining sharp cutting edges and resisting wear, these tools can be used for longer durations without compromising on performance. This longevity translates to cost savings and increased efficiency in machining operations.

Material Removal

Minimal Material Removal

The primary focus of finishing end mills is on minimal material removal. This approach allows for the fine-tuning of the workpiece geometry and ensures that only the necessary amount of material is removed to achieve the desired finish. It reduces waste and improves resource utilization in the manufacturing process.

Choosing an End Mill

Milling Performance and Durability

High-Speed Milling

For applications requiring high-speed milling, choosing end mills made from robust materials such as carbide is essential. These tools can withstand the high temperatures and stresses associated with high-speed operations, providing consistent performance and durability.

Coating Resistance

The coating on an end mill significantly affects its performance and durability. Coated end mills, such as those with TiAlN or AlTiN coatings, offer superior resistance to heat and wear, enhancing the tool’s lifespan and enabling it to perform better under demanding conditions.

Cutter Diameter

Slot Width

The diameter of the cutter must align with the slot width required in the machining operation. Selecting the appropriate cutter diameter ensures that the slots are milled to the correct dimensions, reducing the need for additional finishing and improving overall efficiency.

Tool Rigidity

A larger cutter diameter generally provides better tool rigidity, reducing deflection and improving accuracy. This rigidity is particularly important in operations that involve high cutting forces or require precise dimensions.

Length of Cut

Contact Length

The length of cut must correspond to the contact length required in the machining process. Ensuring the correct length allows for optimal engagement of the cutting edges with the material, enhancing cutting efficiency and tool performance.

Overhang and Rigidity

Minimizing the overhang of the end mill helps in maintaining tool rigidity. Excessive overhang can lead to deflection, reduced accuracy, and increased wear. Choosing the correct tool length ensures stability and precision in the cutting process.

Tool Profile

Square Profile

Square profile end mills are versatile tools suitable for general-purpose milling applications. They are ideal for operations requiring flat surfaces and right-angle profiles, providing good performance across various materials.

Corner Radius Profile

End mills with a corner radius profile offer enhanced strength and reduced chipping compared to square end mills. The rounded corners distribute cutting forces more evenly, extending tool life and improving surface finish.

Ball Profile

Ball profile end mills are designed for contour milling applications. Their rounded ends make them ideal for creating 3D shapes, molds, and complex geometries, achieving smooth and precise finishes.

Material of the Tool

Carbon Steel

End mills made from carbon steel are affordable options for general-purpose machining. While they offer good performance in many applications, they are less durable than higher-grade materials and may not be suitable for high-speed or high-precision operations.

HSS (High-Speed Steel)

HSS end mills provide a good balance of performance and cost. They are tougher than carbon steel and can handle higher cutting speeds, making them suitable for a wide range of applications, including complex and intricate milling tasks.

Cobalt-bearing HSS

Cobalt-bearing HSS end mills offer enhanced performance and durability compared to standard HSS tools. The addition of cobalt improves heat resistance and wear properties, making them ideal for tougher materials and more demanding applications.

Cemented Carbide

Cemented carbide end mills are known for their exceptional hardness and wear resistance. They maintain sharp cutting edges even at high temperatures, providing superior performance in high-speed and high-precision milling operations.

Material You Are Cutting

Mechanical Properties

The mechanical properties of the material being machined play a crucial role in end mill selection. Harder materials require end mills with higher wear resistance and toughness, while softer materials can be machined with less robust tools.

Tool Geometry Suitability

The geometry of the end mill must be suitable for the material being machined. Different materials may require specific cutting angles, flute configurations, and coating types to optimize performance and achieve the best results.

Number of Flutes

Feed Rate

The number of flutes on an end mill affects the feed rate and cutting performance. A higher number of flutes allows for smoother finishes but may reduce chip evacuation efficiency. Balancing the number of flutes with the desired feed rate is key to achieving optimal results.

Chip Space

The space between flutes affects chip evacuation. More flutes result in smaller chip spaces, which can hinder chip evacuation in some materials. Selecting the appropriate flute count ensures efficient material removal and prevents tool clogging.

High Speed with Good Chip Evacuation

Tool Geometry

The geometry of the end mill, including the helix angle and flute design, plays a crucial role in chip evacuation. Tools with optimized geometry provide better chip flow, reducing cutting forces and enhancing performance at high speeds.

Tool Coating

Tool coatings, such as TiN, TiCN, and AlTiN, enhance chip evacuation by reducing friction and heat buildup. Coated end mills improve performance in high-speed operations, extending tool life and maintaining cutting efficiency.

Tips for Working with End Mills

Tooling Selection

Material and Project

Selecting the right tooling for the material and project is essential. Different materials require specific tool properties, and the complexity of the project may dictate the type of end mill needed. Understanding the requirements of the job ensures the best tooling choice.

Speed and Feed Rate

Optimal Speed Matching

Matching the cutting speed to the material and tool properties is vital for efficient milling. Operating at the right speed enhances cutting performance and prolongs tool life, providing better results.

Speed Reduction for Tool Life

Reducing the speed slightly can significantly extend tool life without compromising quality. This approach prevents overheating and excessive wear, ensuring consistent performance over prolonged use.

Chip Evacuation

Cutting Quality

Effective chip evacuation is crucial for maintaining cutting quality. Ensuring that chips are efficiently removed from the cutting area prevents clogging, reduces heat buildup, and improves surface finish.

Use of Coolant

Preventing Chip Build-up

Using coolant helps in preventing chip build-up, cooling the tool, and lubricating the cutting process. Proper coolant application enhances tool life and cutting performance, particularly in high-speed and high-volume operations.

Maximizing Cutting Edges

Increasing Surface Area

Maximizing the use of cutting edges increases the surface area involved in the cutting process, reducing wear on individual edges and enhancing overall tool performance. Utilizing the entire cutting edge ensures efficient material removal and prolonged tool life.

Tooling for High Production

Use of Carbide End Mills

For high-production environments, carbide end mills offer the best performance. Their superior hardness and wear resistance make them ideal for continuous operation, providing consistent results and reducing downtime for tool changes.

Handling Extra-Length End Mills

Use of Rigid End Mills

Extra-length end mills require careful handling to maintain rigidity and prevent deflection. Using rigid end mills supports stability and accuracy, ensuring precise cuts even with extended tool lengths.

Final Thoughts on Roughing vs. Finishing End Mills

Importance of Choosing the Right Tool

Success of CNC Machining Projects

Choosing the right end mill is critical to the success of CNC machining projects. The correct tool selection enhances efficiency, ensures precision, and reduces wear, leading to better overall performance and successful project outcomes.

Summary of Differences

Roughing vs. Finishing End Mills

Roughing end mills are designed for rapid material removal and bulk cutting, characterized by their serrated teeth and robust construction. In contrast, finishing end mills focus on achieving high precision and fine finishes, featuring more flutes and refined cutting edges. Understanding these differences is crucial for selecting the appropriate tool for each machining stage.

Final Considerations for Efficiency and Precision in Milling

Efficient and precise milling requires careful consideration of various factors, including tool selection, material properties, and machining parameters. By understanding the functions, characteristics, and advantages of roughing and finishing end mills, users can optimize their machining processes, improving productivity and achieving superior results. Properly applying these insights ensures a seamless transition from roughing to finishing, delivering high-quality machined parts that meet exact specifications.